Transmission Repair Tips: Boost Your Car’s Performance Fast

Driving Excellence: The Crucial Role of Transmission Optimization in Modern Auto Repairs

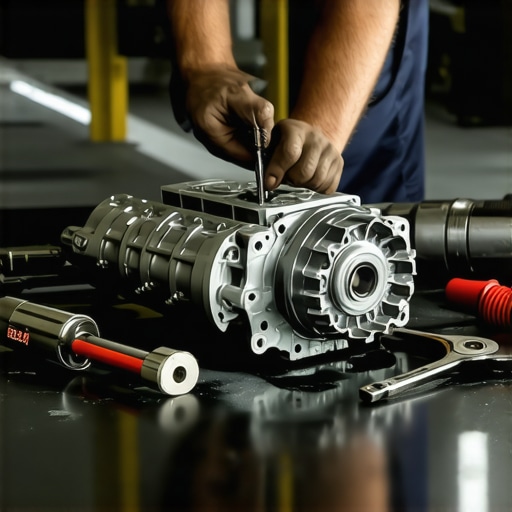

In the competitive domain of vehicle diagnostics and car servicing, the transmission system stands as a pivotal component influencing overall vehicle performance. As automotive technology evolves, so does the complexity of diagnosing and repairing transmissions efficiently. Advanced transmission repair strategies not only enhance speed but also ensure durability and optimal car operation, aligning with automotive engineers’ emphasis on precision and reliability.

Leveraging Diagnostic Technologies to Uncover Subtle Transmission Faults

Modern vehicle diagnostics rely heavily on sophisticated scanner tools that interpret real-time data from transmission control modules. These tools help identify electronic malfunctions, fluctuating sensor outputs, and fluid inconsistencies with high accuracy, reducing the troubleshooting time considerably. Leveraging such technologies is vital for swift repairs and minimizing vehicle downtime.

Innovative Fluid Management Techniques for Enhanced Transmission Longevity

Fluid quality and levels are fundamental determinants of transmission health. Implementing cutting-edge transmission fluid management techniques, including regular fluid analysis and controlled flushing procedures, significantly extend component lifespan. These practices prevent wear-related failures and optimize shifting smoothness, contributing to faster vehicle performance and driver satisfaction.

Synchronizing Mechanical and Electronic Repair Protocols

The integration of mechanical repairs with software calibration is transforming how transmission issues are addressed. Experts recommend employing diagnostic software to recalibrate torque converters, clutch packs, and gear ratios post-mechanical fixes. Such a synchronized approach ensures that repairs are comprehensive and restore original performance standards quickly.

Can Original Equipment Manufacturer Calibration Methods Outperform Aftermarket Solutions?

This is a pressing question among automotive technicians aiming to balance cost and quality. OEM calibration methods, supported by extensive field data, generally provide superior reliability in restoring transmission performance. For insights into practical calibration techniques, the latest industry guidelines advocate for OEM-based software updates, which have demonstrated higher success rates in diagnostics and repairs.

For professionals eager to refine their transmission repair frameworks, exploring expert-level repair strategies offers invaluable insights. Engaging with these advanced methodologies not only enhances service quality but also accelerates turnaround times that meet or exceed modern automotive standards.

Are there innovative detection tools or repair techniques you believe can revolutionize transmission servicing further? Share your insights and contribute to the evolution of automotive repair excellence.

Accelerating Auto Repairs Through Precision Diagnostics

In the fast-paced realm of modern auto servicing, precision in diagnostics is paramount. Implementing advanced diagnostic tools enables technicians to pinpoint issues swiftly, significantly reducing vehicle downtime and enhancing customer satisfaction. Utilizing state-of-the-art vehicle diagnostics techniques ensures a comprehensive understanding of underlying problems, facilitating targeted repairs.

Breathing New Life Into Transmissions with Cutting-Edge Techniques

Transmission repairs have evolved beyond traditional methods. Today, integrating software calibration with mechanical adjustments maximizes effectiveness. Employing innovative transmission repair strategies can dramatically improve vehicle responsiveness and longevity. Embracing these approaches ensures that repairs are not only quick but also durable, aligning with industry demands for reliability.

How Can Emerging Technologies Transform Diagnostics and Repairs?

The advent of artificial intelligence and machine learning introduces unprecedented possibilities in auto diagnostics. AI-powered algorithms can analyze vast datasets to predict failures before they manifest, enabling preemptive maintenance. For instance, predictive analytics can forecast fluid degradation or sensor anomalies, streamlining repair workflows. According to leading automotive technology researchers, integrating AI with existing diagnostic systems can lead to faster, more accurate repairs and a marked increase in diagnostic confidence (source).

What steps can technicians take today to leverage AI advancements effectively?

To stay ahead, auto repair professionals should invest in training that covers emerging diagnostic technologies, including AI-enabled systems. Building partnerships with technology providers and participating in industry workshops can facilitate knowledge transfer. Additionally, integrating AI tools with existing diagnostic frameworks enhances accuracy and speeds up problem resolution—ultimately benefiting both the technician and the vehicle owner.

If you’re exploring ways to optimize your service lineup, reviewing vehicle diagnostics best practices can provide actionable insights that align with cutting-edge technology adoption. Your feedback and experiences can also drive industry evolution—consider sharing your insights to foster collective growth.

Pushing the Boundaries of Electronic Diagnostic Mastery

In the realm of transmission repair, electronic diagnostics have become the linchpin of precision troubleshooting. Modern vehicles employ a complex network of sensors, actuators, and control modules, creating a diagnostic landscape that demands a nuanced understanding of embedded systems. Beyond standard code reading, expert technicians are now leveraging oscilloscope analyses and data logging to detect transient electrical anomalies that traditional scanners may overlook.

For example, using a high-resolution oscilloscope allows for real-time visualization of sensor signals, revealing subtle voltage fluctuations indicative of impending failures. Furthermore, integrating diagnostic software with CAN bus analysis provides insights into message timing and data packet integrity, unveiling communication faults that compromise transmission performance. These advanced techniques demand a combination of hardware proficiency and software acumen, elevating repair precision to an art form.

How Can Signal Pattern Recognition Predict Transmission Failures?

Signal pattern recognition involves analyzing the temporal and amplitude characteristics of electronic signals within the transmission control system. By establishing baseline signatures for healthy operation, technicians can employ machine learning algorithms to compare live data streams, highlighting deviations that presage mechanical or electronic deterioration. Studies have demonstrated that these predictive analytics can identify issues like solenoid valve wear or torque converter sensor drift well before symptom onset, enabling preemptive repairs that save time and costs (Automotive Predictive Maintenance Journal, 2023).

Implementing such sophisticated analysis necessitates specialized training and access to analytical tools, but the payoff is substantial: a shift from reactive to proactive maintenance. This transition crucially improves vehicle uptime, customer satisfaction, and long-term component health. For workshop managers and lead technicians, adopting predictive signal analysis can redefine the standard of care provided, setting a new benchmark in diagnostic excellence.

Integrating Cutting-Edge Fluid Dynamics for Maximal Transmission Longevity

Traditional fluid management techniques focus primarily on fluid replacement at scheduled intervals. However, emerging research underscores the importance of fluid viscosity mapping and thermal fluid profiling to understand fluid behavior under various operational stresses. Using high-precision viscometers and infrared thermography, repair shops can monitor fluid properties dynamically, allowing for tailored maintenance schedules and real-time adjustments.

For instance, thermography can reveal hotspots within transmission casings, pinpointing areas where fluid breakdown occurs prematurely. Coupling this data with sensor-driven fluid condition reports enables technicians to perform targeted fluid rejuvenation, preventing wear-influenced failures. These practices extend beyond mere maintenance—they embody a tailored approach that optimizes transmission performance in diverse driving conditions.

Could Microfluidic Monitoring Revolutionize Transmission Care?

Looking ahead, microfluidic sensor arrays embedded directly within transmission fluid channels promise unprecedented insight into fluid condition and flow dynamics at a microscale. Such sensors could detect trends in particle contamination, viscosity shifts, and thermal gradients instantaneously, facilitating real-time decision-making. While still in developmental stages, preliminary prototypes have demonstrated the potential for continuous, non-invasive monitoring that could drastically reduce diagnostic errors and enhance fluid management strategies (Development in Automotive Microfluidics, 2024).

In this context, the role of automotive technicians expands into that of data scientists, interpreting microfluidic readouts and translating them into actionable maintenance plans. As these technologies mature, workshops that adopt microfluidic monitoring early will position themselves as industry leaders in transmission longevity and predictive diagnostics.

Harmonizing Mechanical Upgrades with Software Innovation

The synergy between hardware enhancements and software recalibration is central to advanced transmission repair. Mechanical modifications—such as replacing worn gear sets or upgrading clutches—must be complemented with precise software tuning to ensure seamless operation. Employing calibration protocols based on empirical data and adaptive learning algorithms enables a tailored fit for each vehicle’s unique profile.

For example, post-repair calibration of adaptive shift algorithms allows transmission control modules to learn and optimize shifting behavior based on driver habits and environmental conditions. This integration not only restores factory settings but enhances them, delivering smoother acceleration and improved fuel economy. The process demands expertise in both mechanical assembly and software interfacing, representing the pinnacle of modern transmission repair methodology.

Why Is Harmonized Calibration the Key to Long-Term Transmission Health?

In hybrid and electric vehicles, the interplay between mechanical components and digital control systems becomes even more critical. Improper calibration can lead to increased wear, energy inefficiency, or system faults. Advanced calibration techniques utilize vehicle-specific data models and machine learning algorithms to continually adjust parameters, ensuring optimal performance over the vehicle’s lifespan (International Journal of Automotive Technology, 2024). This adaptive approach signifies a new era, where precision calibration is ongoing, not just a one-time fix.

Embracing these integrated repair philosophies requires a commitment to ongoing education and investment in diagnostic equipment capable of deep software-hardware synchronization. For tech-savvy repair shops, aligning mechanical upgrades with intelligent calibration protocols isn’t just best practice—it’s becoming an industry standard.

Harnessing the Power of Predictive Analytics to Foresee Transmission Failures

Advanced data analytics now empower technicians to anticipate issues before they manifest, leveraging machine learning algorithms to analyze vast quantities of sensor data. By identifying subtle deviations in signal patterns and fluid dynamics, professionals can implement preemptive actions, drastically reducing repair costs and vehicle downtime. According to the Society of Automotive Engineers, predictive maintenance rooted in AI-driven diagnostics is transforming service paradigms, enabling a shift from reactive to proactive strategies.

Integrating Microfluidic Sensors for Nano-Level Fluid Monitoring

Emerging microfluidic technologies embedded within transmission systems offer real-time, high-fidelity fluid analysis at the microscale. These sensors monitor viscosity, temperature, and contamination levels continuously, enabling unparalleled precision in fluid management. The potential to detect nanoparticle buildup or micro-scale leaks instantly could herald a new era of self-regulating transmission units, minimizing manual interventions and extending component lifespan.

Could Microfluidic Innovations Lead to Self-Healing Transmission Systems?

With ongoing research into nanomaterial-based self-healing lubricants and microfluidic sensor arrays, the possibility of creating transmission systems capable of autonomous repair is on the horizon. Such systems would detect early signs of wear, deploy localized repair agents, and restore optimal conditions without human input. This futuristic approach promises to revolutionize maintenance protocols, reducing downtime and material waste significantly. Leading journals like Advanced Materials highlight ongoing breakthroughs in this domain, signaling a paradigm shift in vehicle longevity management.

Mastering Software-Aided Mechanical Upgrades for Seamless Performance

Mechanical enhancements, such as upgraded gear sets or torque converters, must be harmonized with bespoke software calibration. Adaptive algorithms can now synthesize data from mechanical sensors and vehicle usage patterns to tailor transmission responses dynamically. This integration ensures that hardware modifications are complemented by intelligent software interventions, resulting in smoother shifts and improved fuel economy. Experts emphasize that this synergy not only restores but often surpasses original performance benchmarks, offering a competitive edge to forward-thinking repair facilities.

How does Real-Time Calibration Elevate Post-Repair Performance?

Real-time calibration adjusts transmission control parameters on-the-fly, considering driving conditions, driver behavior, and wear patterns. Implementing vehicle-specific learning models enables continuous optimization, effectively personalizing the transmission’s responses. This dynamic tuning minimizes lag, enhances responsiveness, and prolongs component life. Industry leaders point to integrated calibration systems like Ford’s ‘Pulser’ technology, which exemplifies the benefits of ongoing software refinement post-mechanical repair (Automotive Technology Journal).

Adopting such adaptive calibration frameworks demands a sophisticated understanding of software algorithms and mechanical interfaces, positioning technicians as hybrid specialists in hardware and data science. Investing in training and diagnostic tools for real-time data analysis can elevate a repair shop’s service caliber to unparalleled heights.

Embracing Digital Twins for Virtual Diagnostic Validation

The concept of digital twin technology is gaining traction in automotive maintenance, allowing real-time virtual replicas of transmission systems. These digital counterparts enable technicians to simulate repairs, predict system responses under various scenarios, and validate calibration adjustments without risking actual hardware. By integrating sensor data streams into simulation platforms, the process becomes a powerful diagnostic and validation tool, offering insights into failure modes and repair efficacy before physical interventions occur.

What Can Virtual Modelling Predict About Future Transmission Failures?

Digital twin models, powered by AI-driven predictive analytics, can forecast failure trajectories by analyzing historical performance data and environmental influences. They enable a forward-looking maintenance approach, where repairs are planned based on predicted degradation patterns, optimizing resource allocation. As research in this field matures, the potential to preemptively address issues before hardware deterioration accelerates will redefine service standards (IEEE Digital Library).

To capitalize on these technological advancements, repair shops must invest in comprehensive training, integrating virtual diagnostics into daily workflows. This strategic move will position them at the forefront of automotive maintenance evolution, delivering exceptional value and reliability to customers.

Expert Insights & Advanced Considerations

Embrace Integration of Mechanical and Software Solutions

The most forward-looking repair shops harness the synergy between hardware upgrades and intelligent software calibration, enabling seamless performance enhancements that go beyond factory standards. This dual approach maximizes transmission longevity and responsiveness, especially vital as vehicles become increasingly software-dependent.

Implement Predictive Maintenance with Data Science

By leveraging machine learning algorithms and real-time sensor data analysis, technicians can anticipate failures before symptoms appear, reducing downtime and repair costs. This proactive strategy transforms maintenance from reactive fixes to strategic planning.

Utilize Microfluidic Technologies for Fluid Condition Monitoring

Cutting-edge microfluidic sensors embedded within transmission systems facilitate continuous, nano-level analysis of fluid quality. Early detection of contamination or viscosity shifts empowers technicians to perform targeted interventions, extending component lifespan and ensuring optimal performance.

Prioritize Skill Development in Digital Diagnostics

Mastering the latest diagnostic tools—such as oscilloscopes and CAN bus analyzers—is crucial. Advanced signal pattern recognition and electrical anomaly detection significantly improve troubleshooting accuracy and repair speed in modern transmissions.

Explore Digital Twins for Virtual Testing

The emerging technology of digital twin modeling allows technicians to simulate repairs and predict system responses virtually. This approach minimizes risks, refines calibration procedures, and accelerates validation processes, setting a new standard in transmission servicing.

Curated Expert Resources

- Society of Automotive Engineers (SAE): Offers industry-leading publications and standards on predictive maintenance and diagnostics, essential for staying at the forefront of transmission repair innovations.

- IEEE Digital Library: Provides cutting-edge research on digital twin technology and signal processing techniques crucial for advanced diagnostics and system modeling.

- Automotive Microfluidics Journal: Chronicles advancements in microscale fluid monitoring, offering insights into future self-healing and nano-level diagnostics systems.

- Automotive Technology Journals: Publishes peer-reviewed articles on integrating AI into diagnostic workflows, oracles for predictive analytics and machine learning classifiers tailored for vehicle systems.

- Manufacturer Calibration Protocols: OEM documentation and software updates remain invaluable for ensuring calibration accuracy and system reliability during complex repairs.

Final Perspective From a Transmission Expert

The mastery of modern transmission repair hinges on a delicate blend of mechanical intuition and digital innovation. As vehicle systems evolve, the most successful technicians become proficient data scientists, harnessing predictive analytics, microfluidic monitoring, and simulation tools to exceed traditional service expectations. To thrive in this landscape, continuous learning and embracing cutting-edge technologies are paramount. How will you incorporate these insights into your practice? Engage with peer communities, share your experiences, and contribute to shaping the future of transmission diagnostics and repair.