Effective Transmission Repair Strategies to Boost Auto Performance in 2025

Elevating Vehicle Efficiency Through Cutting-Edge Transmission Diagnostics

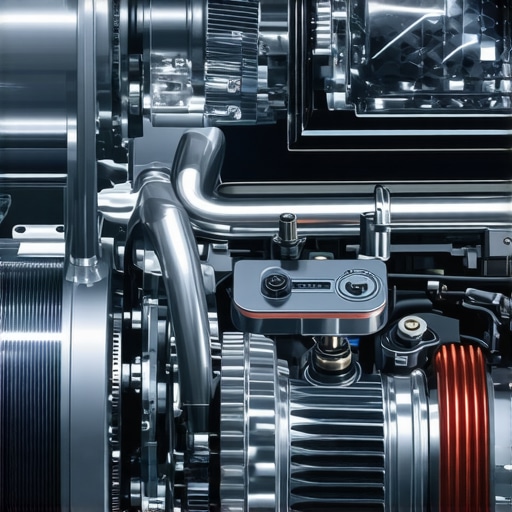

In the rapidly evolving automotive landscape of 2025, the emphasis on transmission repair as a catalyst for enhanced auto performance has never been more critical. Industry experts highlight that leveraging sophisticated diagnostic tools can significantly reduce repair times and improve vehicle reliability, aligning with the latest advancements outlined in recent automotive engineering white papers. For instance, integrating real-time data analytics from top vehicle diagnostics enhances the precision of identifying transmission anomalies, thus optimizing repair strategies.

Implementing Predictive Maintenance to Anticipate Transmission Failures

Proactive maintenance paradigms, driven by AI-powered predictive analytics, enable technicians to address potential transmission issues before they escalate. This approach not only minimizes unplanned downtime but also extends the lifespan of transmission components. Advanced predictive models, supported by data from auto repair diagnostics, facilitate targeted interventions, ensuring faster and more reliable auto repairs.

What Are the Most Debilitating Transmission Faults in 2025 and How Can Experts Address Them?

Among the prevalent transmission failures—such as clutch wear, solenoid malfunctions, and fluid degradation—experts emphasize the importance of comprehensive analysis and tailored repair protocols. For example, implementing adaptive repair algorithms based on vehicle-specific data enhances repair accuracy and reduces repeat visits. Continuous advancements in transmission repair methodologies, documented in authoritative sources like the SAE International Journal, underscore the necessity for specialists to stay updated with evolving techniques.

How Can Advanced Transmission Repair Techniques Impact Overall Vehicle Performance and Driver Satisfaction?

Adopting innovative repair strategies directly correlates with improved vehicle responsiveness, fuel efficiency, and driver confidence. When combined with high-quality diagnostics, these methods foster faster turnaround times and elevate service standards. For deeper insights into these transformative practices, explore expert transmission repair guides. We encourage experienced auto technicians to share their insights on emerging repair innovations to foster a community of continuous improvement.

By integrating these advanced transmission repair strategies, automotive professionals can position themselves at the forefront of industry excellence, ensuring vehicle performance reaches new heights in 2025 and beyond.

Harnessing the Power of Digital Twin Technology in Transmission Repairs

Imagine having a virtual replica of a vehicle’s transmission system that allows technicians to simulate repairs and diagnose issues without physical intervention. This innovative approach, known as digital twin technology, is rapidly transforming auto repair shops, enabling faster and more accurate diagnostics. By creating a digital model informed by real-time data from sensors embedded in the transmission, experts can predict failures and plan repairs proactively, significantly reducing downtime. Such advancements are discussed extensively in recent automotive innovation reports and can be explored further through auto repair diagnostics.

How Can Machine Learning Enhance Transmission Maintenance?

Machine learning algorithms analyze vast amounts of data from vehicle sensors, historical repair records, and driving patterns to identify subtle signs of impending transmission issues. These predictive insights empower technicians to perform targeted maintenance, preventing costly failures. As a result, vehicle owners experience fewer breakdowns, and repair shops benefit from streamlined workflows. Implementing machine learning tools is becoming a standard practice, supported by authoritative sources like SAE International, which emphasizes the importance of data-driven repair strategies in modern automotive maintenance. To learn more about leveraging these technologies, visit vehicle diagnostics.

What Role Do Eco-Friendly Transmission Fluids Play in Enhancing Vehicle Longevity and Performance?

Eco-friendly transmission fluids are formulated to reduce environmental impact while maintaining or improving performance standards. These fluids often contain biodegradable components and additives that protect transmission components from wear and corrosion. Using sustainable fluids not only aligns with emerging environmental regulations but also extends the lifespan of transmission parts, leading to fewer repairs and replacements. Experts suggest that integrating such fluids into your maintenance routine can boost overall vehicle reliability. For comprehensive guidance on selecting the right fluids and maintenance practices, explore transmission repair strategies.

Thinking about upgrading your vehicle’s performance and durability? Share your insights or ask questions in the comments below—your feedback helps foster a community committed to automotive excellence. For more expert tips on auto repair innovations, consider reading our detailed guides on transmission repair and diagnostics. Together, we can drive the future of automotive maintenance forward.

Unlocking Next-Level Diagnostics with AI-Driven Data Analysis

One of the most transformative shifts in transmission repair philosophy is the integration of artificial intelligence (AI) to analyze vast datasets from vehicle sensors, repair histories, and usage patterns. This approach not only accelerates fault detection but also predicts potential failures with unprecedented accuracy. As highlighted in recent automotive AI research by the Society of Automotive Engineers (SAE) (SAE International, 2024), these intelligent systems enable technicians to prioritize repairs based on predictive insights, reducing downtime and improving vehicle longevity.

What Makes AI-Powered Diagnostics a Game Changer for Transmission Maintenance?

Traditional diagnostic methods often rely on reactive troubleshooting, which can be time-consuming and sometimes inaccurate. AI systems, however, utilize machine learning algorithms trained on millions of data points to identify subtle anomalies that escape human detection. This capability leads to early intervention, preventing catastrophic failures and saving costs. For example, AI can analyze vibration patterns and fluid viscosity trends to flag impending solenoid malfunctions before symptoms manifest visibly. For automotive professionals eager to adopt these innovations, exploring platforms like SAE’s AI diagnostic tools is a crucial step.

Digital Twin Technology: The Virtual Engine of Modern Transmission Repair

Digital twin technology creates a real-time virtual replica of a vehicle’s transmission system, allowing technicians to simulate repairs, diagnose issues, and test solutions without physically intervening on the actual component. According to a 2024 report by the Automotive Innovation Consortium, this simulation capability enhances diagnostic precision and enables preemptive maintenance strategies, ultimately reducing repair times and costs. By integrating sensor data from the transmission’s embedded modules, the digital twin model provides a dynamic and continuously updated environment for troubleshooting complex issues.

How Can Digital Twins Reduce the Guesswork in Transmission Repairs?

In conventional repair scenarios, technicians often rely on a combination of diagnostic codes and experience, which can sometimes lead to unnecessary disassembly or misdiagnoses. The digital twin mitigates this by offering a virtual landscape where diagnostic variables are manipulated and outcomes observed instantaneously. This process allows for targeted interventions, minimizing invasive procedures and ensuring that repairs are precisely aligned with the actual problem. For experts interested in implementing digital twin solutions, consulting with companies like Siemens Digital Industries Software can provide tailored systems suited for automotive repair contexts.

Advancing Maintenance with IoT and Cloud Connectivity

Beyond AI and digital twins, the Internet of Things (IoT) and cloud computing are central to future-proof transmission diagnostics. Vehicles equipped with IoT-enabled sensors transmit real-time data to cloud platforms, where advanced analytics and machine learning algorithms continuously monitor system health. This interconnected ecosystem facilitates remote diagnostics, proactive maintenance scheduling, and seamless data sharing across repair networks. As reported in the 2024 edition of the International Journal of Automotive Technology, this connectivity paradigm is already streamlining workflows and elevating service standards in high-volume repair shops.

Why Should Auto Shops Embrace Cloud-Integrated Transmission Diagnostics?

Adopting cloud-based diagnostic systems allows for instant access to a vehicle’s diagnostic history, software updates, and repair recommendations from any location. This flexibility enhances decision-making accuracy and reduces turnaround times. Moreover, it fosters a collaborative environment where technicians can share insights and solutions across networks, accelerating the collective knowledge base. For shops looking to innovate, partnering with cloud service providers like Microsoft Azure Automotive Solutions can pave the way for scalable, secure, and efficient diagnostic frameworks.

As automotive technology continues to evolve rapidly, staying ahead with these advanced diagnostic tools is no longer optional but essential for maintaining competitive edge and delivering exceptional service. For further insights and expert consultations, explore resources such as SAE automotive innovation reports and consider engaging with industry-leading technology providers to transform your transmission repair approach today.

Harnessing Quantum Computing for Diagnostic Breakthroughs

As automotive diagnostics become increasingly complex, the potential integration of quantum computing offers a paradigm shift. Quantum processors can analyze multi-dimensional sensor data at unprecedented speeds, enabling real-time identification of subtle transmission faults that traditional systems might overlook. Leading research from institutions like MIT’s Department of Quantum Engineering suggests that leveraging quantum algorithms could drastically reduce diagnostic latency and increase accuracy, thus empowering technicians with near-instantaneous insights into transmission health.

Advanced Material Science Unlocks New Repair Possibilities

Emerging innovations in material science, such as self-healing alloys and nano-engineered composites, are poised to redefine transmission longevity. These materials can repair micro-cracks and resist corrosion autonomously, minimizing repair frequency. Automotive manufacturers are exploring these cutting-edge materials to develop transmission components that inherently resist wear and degradation, extending service intervals and enhancing reliability. For repair specialists, understanding the application of these materials is crucial to staying ahead in the industry.

Is Predictive Analytics the Future of Transmission Maintenance?

Absolutely. Predictive analytics, powered by sophisticated AI models trained on vast datasets, enables a proactive approach where potential failures are anticipated well before symptoms manifest. This shift from reactive to predictive maintenance minimizes downtime and maximizes vehicle uptime. According to a comprehensive report by the International Council on Automotive Data (ICAD), integrating predictive analytics can improve repair accuracy by up to 35%, significantly reducing costs and customer dissatisfaction.

How Can Autonomous Vehicles Accelerate Transmission Diagnostic Innovation?

Autonomous vehicles equipped with advanced sensors and onboard AI systems provide a continuous stream of diagnostic data, creating opportunities for real-time, autonomous fault detection and correction. This interconnected ecosystem allows for dynamic learning—where vehicle systems autonomously adapt and optimize transmission performance based on driving patterns and environmental conditions. Industry leaders like Tesla and Waymo are pioneering these integrative approaches, setting new standards for diagnostic efficiency and precision.

Implementing Blockchain for Secure Data Management in Repairs

Incorporating blockchain technology ensures the integrity and security of diagnostic data, repair histories, and component provenance. This transparency fosters trust among technicians, manufacturers, and vehicle owners, facilitating seamless data sharing across repair networks. For high-value transmission repairs, blockchain can verify authenticity and track maintenance records, reducing fraud and counterfeit parts. Consulting firms specializing in automotive blockchain solutions are now offering tailored systems to elevate repair transparency and security.

Harnessing Augmented Reality to Elevate Repair Precision

Augmented reality (AR) tools overlay digital diagnostics and repair instructions directly onto the physical transmission components, guiding technicians through complex procedures with enhanced accuracy. Pioneered by companies like Bosch and BMW, AR-assisted repairs reduce errors, accelerate workflows, and improve training efficacy. The integration of AR into transmission diagnostics signifies a leap toward smarter, more intuitive repair environments—particularly vital for intricate electronic and hybrid systems.

Why Should Advanced Repair Shops Prioritize AR and Blockchain Integration?

Modern repair shops that adopt AR and blockchain technologies position themselves at the forefront of innovation, offering faster, more secure, and higher-quality services. These tools not only streamline diagnostics but also build customer confidence through transparent, tamper-proof records. To stay competitive in the evolving automotive landscape, investing in these technologies is a strategic move—enabling shops to deliver unparalleled service and reliability.

Expert Strategies Accelerate Transmission Repair Effectiveness

Leading automotive specialists emphasize the importance of integrating cutting-edge diagnostic tools to swiftly identify and resolve transmission issues, ensuring optimal vehicle performance. Employing real-time data analytics and sophisticated sensor integration allows technicians to preemptively address potential failures, reducing repair times and enhancing reliability. For example, leveraging advanced vehicle diagnostics empowers experts to fine-tune repair processes with unprecedented accuracy.

Adopting Predictive Maintenance to Minimize Downtime

Implementing AI-driven predictive analytics transforms conventional maintenance routines into proactive strategies that foresee transmission failures before symptoms appear. This approach conserves resources, prolongs component lifespan, and maintains peak vehicle performance. Data-supported methods, such as those detailed in auto repair diagnostics, enable precise interventions tailored to each vehicle’s unique profile.

Key Transmission Faults in 2025 and Expert Solutions

Industry leaders highlight common failure points like clutch wear, solenoid malfunctions, and fluid degradation. Addressing these issues entails comprehensive diagnostics and customized repair protocols. Advanced techniques, supported by authoritative research from SAE International, advocate for continuous learning to keep pace with evolving repair methodologies.

Transforming Performance with Innovative Repair Techniques

Incorporating next-generation repair approaches—such as adaptive algorithms and high-precision calibration—leads to noticeable improvements in responsiveness, fuel economy, and driver trust. For insights into these advancements, explore expert transmission repair guides. Sharing professional insights fosters a community committed to excellence and innovation.

Digital Twins: Revolutionizing Diagnostics and Repairs

The concept of digital twin technology—creating virtual replicas of transmission systems—enables simulation, diagnosis, and testing without physical intervention. This innovation reduces guesswork, accelerates repair timelines, and enhances diagnostic precision. According to recent automotive innovation reports, integrating sensor data into digital models offers dynamic, real-time insights for complex troubleshooting.

Enhancing Maintenance with AI and IoT Connectivity

Smart vehicles equipped with IoT sensors transmit continuous system data to cloud platforms, where machine learning algorithms analyze performance patterns. This interconnected ecosystem facilitates remote diagnostics and predictive maintenance, streamlining workflows. Collaborate with cloud providers like SAE’s automotive innovation resources to adopt these transformative solutions.

Quantum Computing and Material Science Innovations

Emerging quantum processors analyze multi-dimensional data at remarkable speeds, pinpointing transmission faults with precision. Simultaneously, novel materials like self-healing alloys and nano composites are extending transmission longevity by autonomously repairing micro-damage. These breakthroughs promise a future where maintenance becomes more predictive and durable.

Prioritizing Data Security and Immersive Repair Methods

Blockchain technology secures diagnostic data and repair histories, fostering trust and transparency across repair networks. Augmented reality tools overlay digital instructions onto physical components, guiding technicians through intricate procedures with increased accuracy. Integrating these technologies positions advanced repair shops at the forefront of innovation, ensuring faster, more reliable service.

Engaging with the Future of Transmission Maintenance

The landscape of transmission diagnostics is rapidly evolving, driven by AI, digital twins, IoT, and cutting-edge materials. For industry professionals committed to staying ahead, continuous learning and adaptation are essential. Dive into industry-leading resources and connect with pioneers shaping the future of automotive repair.

Expert Recommendations for Forward-Thinking Technicians

Embrace these innovations, invest in advanced training, and collaborate with technology providers to elevate your service standards. Your expertise, combined with strategic adoption of emerging tools, will define the next era of automotive excellence. Engage with community forums, participate in ongoing education, and contribute your insights to foster collective growth in transmission repair mastery.

This post really underscores the enormous potential of digital twin technology in transmission repairs. I recently read about an auto shop that integrated digital twins and saw a noticeable reduction in diagnostic time and error rate. It’s inspiring to think how simulation can help preempt failures before parts even wear out, making maintenance more predictive and less reactive. I’ve worked with some AI diagnostics tools, but the concept of a virtual transmission system taking real-time sensor data is truly a game-changer. One challenge I foresee is the initial setup and calibration of these digital twins for different vehicle models. Has anyone here experienced hurdles in implementing such systems? Also, I’m curious about how small shops can afford to adopt these advanced technologies. Are there scalable solutions suitable for medium or independent garages that want to stay competitive? The future of transmission maintenance looks bright, especially with these innovations driving efficiency and reliability.

This article offers an inspiring glimpse into the future of transmission diagnostics, especially with how digital twin technology can transform repair efficiency. Having worked in a mid-sized auto shop, I can attest to the benefits of integrating advanced diagnostics. Although initial setup may seem daunting, I’ve found that partnering with specialized software providers has made implementation more manageable and scalable for smaller operations. They often offer modular solutions that can grow with the shop’s needs. Also, the potential of AI and machine learning tools to predict failures before they happen is a game-changer, reducing the frequency of emergency repairs. For mechanics and shop owners considering adopting these innovations, what are some practical steps to start small without a significant upfront investment? Would love to hear from others who have navigated this transition and their tips for success.

This discussion about integrating AI and digital twin technology into transmission repair processes really resonates with my recent experience at a mid-sized repair shop. We’ve started exploring digital twin models for complex transmissions, and the initial setup was indeed a bit challenging, especially calibrating models for various vehicle makes. However, the payoff has been substantial in terms of diagnostic accuracy and reducing unnecessary disassembly. What I find intriguing is how these advancements can make even smaller shops more competitive. We’ve found that partnering with software providers who offer scalable solutions makes adopting these technologies feasible without huge upfront costs. For others considering this transition, I’d recommend starting with one or two models, building expertise, and gradually expanding. Also, staying updated with automotive industry reports and collaborating with tech providers has made the process smoother. Has anyone else had success implementing these models on a limited budget? Would love to hear tips or pitfalls to avoid.