Transmission Repair: Quick & Effective Strategies for 2025

The Evolving Landscape of Transmission Repair: Embracing Technological Advances for Superior Vehicle Diagnostics

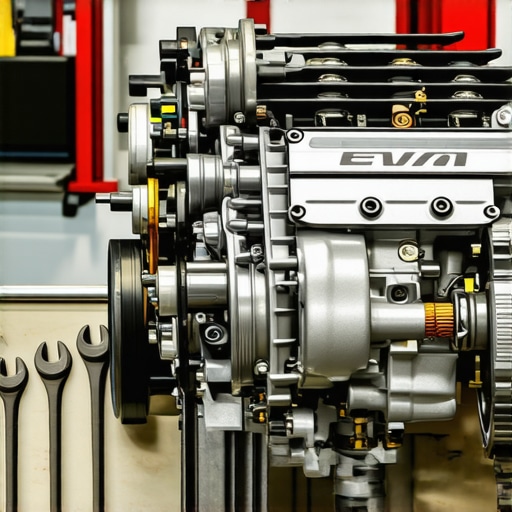

In the realm of automotive maintenance, transmission repair has transitioned from rudimentary mechanical interventions to sophisticated diagnostic procedures driven by cutting-edge technology. As vehicles become increasingly complex, understanding the intersection of auto repair, vehicle diagnostics, and transmission system intricacies is vital for professionals aiming for precision and efficiency.

Integrating Data-Driven Strategies to Accelerate Auto Service Effectiveness

Modern auto repair facilities leverage data analytics to identify root causes of transmission failures swiftly. Employing advanced diagnostic tools, such as scan tools integrated with onboard computer systems, allows technicians to decode fault codes and interpret sensor outputs with heightened accuracy. This integration enables a shift from reactive repairs to proactive maintenance, significantly reducing vehicle downtime.

Deciphering Complex Transmission Failures Through Expert Diagnostics

Transmission issues often manifest through subtle symptoms like delayed shifting or unusual noises. Advanced vehicle diagnostics employ vibrational analysis and fluid analysis to detect anomalies before they escalate into costly repairs. For instance, tracking lubricant viscosity changes can reveal early-stage wear, thereby guiding targeted auto repair interventions. This proactive approach epitomizes the high standards expected in 2025’s automotive service industry.

What Are the Challenges in Diagnosing Modern Transmission Problems?

Determining the Complexity of Electronic Transmission Systems

With the advent of electronic control units (ECUs) managing transmission functions, diagnosing malfunctions requires understanding complex software algorithms and sensor interactions. Technicians must possess not only mechanical expertise but also proficiency in software diagnostics, making continuous training essential. This dual knowledge base ensures rapid identification of issues like solenoid failures or sensor malfunctions, which traditional methods might overlook.

Prioritizing Safety and Reliability in Transmission Repairs

Ensuring vehicle safety is paramount, especially when dealing with components susceptible to rapid degradation. Implementing rigorous testing protocols post-repair, such as dynamic performance testing and fluid analysis, supports maintaining high standards of reliability. Through continuous professional development and adherence to OEM guidelines, auto repair technicians contribute to building customer trust and industry credibility.

Enhancing Customer Satisfaction Through Transparent Diagnostic Processes

Educating clients about the diagnostic procedures and repair strategies fosters transparency and confidence. Providing detailed reports that outline findings and recommended actions demonstrates professionalism. This transparency not only streamlines the repair process but also cements long-term customer relationships in a competitive market.

How Can Technicians Stay Ahead in the Rapidly Changing Field of Transmission Diagnostics?

Engaging with industry seminars, certification programs, and peer-reviewed publications—such as those in the “International Journal of Automotive Technology”—keeps professionals abreast of emerging trends. Investing in state-of-the-art diagnostic equipment further empowers technicians to deliver precision repairs aligned with 2025 industry standards.

For those interested in elevating their vehicle diagnostics capabilities, exploring comprehensive resources such as transmission repair strategies can provide valuable insights. Sharing expert knowledge and practical experiences within professional forums enhances collective expertise, ultimately benefiting vehicle owners seeking reliable auto repair services.

Unveiling Hidden Faults: The Power of Predictive Maintenance in Transmission Diagnostics

Predictive maintenance is revolutionizing auto repair by allowing technicians to anticipate transmission failures before symptoms become apparent. Utilizing predictive analytics, combined with real-time sensor data, enables auto professionals to identify wear patterns and impending faults. This proactive approach minimizes unexpected breakdowns and extends the lifespan of transmission components. Embracing these strategies aligns with industry best practices, as highlighted in authoritative sources like the SAE International technical papers, which emphasize the critical role of sensor integration and data analysis for future-ready diagnostics.

Innovative Tools Transforming Transmission Troubleshooting

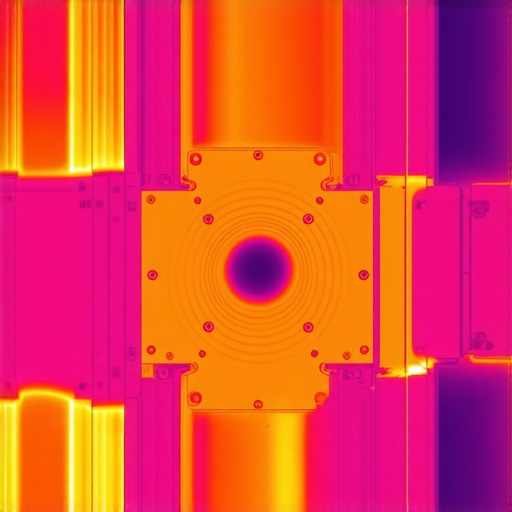

The adoption of advanced diagnostic tools—such as high-resolution oscilloscopes and thermal imaging—has pushed the boundaries of what technicians can detect. These devices help visualize electrical signals and heat anomalies within transmission systems, revealing issues invisible to conventional methods. For example, thermal imaging can pinpoint hotspots caused by slipping clutches or overheated solenoids, enabling targeted repairs with minimal guesswork. Integrating these tools into daily diagnostics enhances accuracy, reduces repair times, and ultimately delivers superior customer satisfaction. Professionals seeking to stay at the forefront of auto repair should consider leveraging these technologies alongside proven strategies documented at auto diagnostics experts.

How Can Diagnostic Innovation Continue to Shape the Future of Transmission Repairs?

As vehicle technology accelerates, the future of transmission diagnostics lies in artificial intelligence and machine learning. AI-driven diagnostic software can analyze vast amounts of sensor data to predict failures, recommend optimal repair timelines, and even suggest personalized maintenance schedules. Such advancements not only enhance diagnostic precision but also empower technicians with decision-support tools, streamlining workflows. Staying informed through scientific journals, like the Autotech Review, ensures professionals adopt cutting-edge practices that elevate their service quality.

For those dedicated to continuous improvement, exploring comprehensive resources such as transmission repair strategies offers valuable insights into integrating emerging technologies into routine diagnostics. Engaging with industry communities and participating in ongoing training programs will further solidify your reputation as a leader in auto repair excellence.

Leveraging Artificial Intelligence to Predict Transmission Failures Before They Occur

As vehicle systems become more interconnected, the integration of artificial intelligence (AI) into transmission diagnostics marks a paradigm shift in auto repair. AI algorithms analyze massive datasets from sensors embedded within transmission components, identifying patterns that precede failures. For example, machine learning models trained on historical fault data can detect subtle variations in torque, temperature, and vibration signals that human technicians might overlook, enabling proactive maintenance strategies.

According to SAE International’s recent publications, AI-enabled diagnostic tools are expected to reduce diagnostic time by up to 40%, leading to faster repairs and minimized vehicle downtime. These innovations facilitate predictive analytics, allowing technicians to schedule interventions precisely when needed, thereby improving reliability and customer satisfaction.

Addressing the Nuances of Sensor Calibration for Precise Transmission Diagnostics

The accuracy of modern diagnostic systems hinges on meticulous sensor calibration. Over time, sensors measuring parameters like fluid viscosity, temperature, and solenoid operation can drift from their baseline readings, introducing errors that compromise fault detection. Fine-tuning these sensors requires an understanding of the specific transmission model, environmental influences, and sensor aging.

For instance, thermal sensors must be calibrated to account for ambient temperature fluctuations, ensuring heat readings reflect true component temperatures. Regular calibration, guided by OEM specifications and utilizing specialized calibration equipment, maintains system integrity and diagnosis precision. Incorporating automated calibration routines within diagnostic software streamlines this process, mitigating human error and enhancing diagnostic confidence.

How Does the Use of Multisensor Data Fusion Enhance Fault Detection?

Combining data from multiple sensors—known as multisensor data fusion—provides a comprehensive picture of transmission health. This approach synthesizes signals such as vibration patterns, fluid characteristics, electrical parameters, and thermal data to improve fault identification accuracy. Advanced algorithms weigh and correlate these data streams, reducing false positives and uncovering complex failure modes.

Research published in IEEE Transactions on Industrial Electronics underscores that multisensor fusion can detect early-stage wear and integrated system malfunctions more effectively than single-sensor analysis. For technicians, mastering data fusion techniques enhances diagnostic depth, ensuring that even nuanced issues are addressed before escalating into costly repairs.

Expanding Diagnostic Horizons with Non-Invasive Inspection Technologies

Non-invasive testing methods are revolutionizing the way transmission troubleshooting is conducted. Thermal imaging cameras visually expose hotspots indicative of slipping clutches or overheating solenoids, while ultrasonic sensors detect high-frequency vibrations associated with bearing wear or gear contact anomalies. These tools facilitate quick, damage-free inspections, preserving vehicle safety and component integrity.

Furthermore, infrared thermography can reveal uneven heat distribution within transmission housings, suggesting lubrication deficiencies or internal friction points. To maximize diagnostic effectiveness, technicians should incorporate these technologies routinely, complemented by data interpretation expertise rooted in physics and engineering principles.

Driving the Evolution of Transmission Repair with Industry Standards and Certification

Staying ahead in this rapidly evolving field demands adherence to industry standards and continuous professional development. Organizations like the Automotive Service Excellence (ASE) and OEM-specific training programs set benchmarks for diagnostic proficiency, safety, and quality assurance. Certifications in advanced vehicle diagnostics signal a technician’s mastery over complex systems and emerging technologies.

Engagement with industry conferences, like the SAE World Congress, offers exposure to cutting-edge innovations such as real-time data analytics and AI-integrated diagnostic platforms. These forums facilitate knowledge exchange and foster collaboration among auto repair professionals committed to excellence in transmission repair practices.

As industry leaders push the boundaries, the question remains: How can individual auto repair shops harness these innovations to differentiate themselves in a competitive market? Investing in training, state-of-the-art diagnostic tools, and a culture of continuous learning is essential. To explore practical implementation strategies, consider consulting comprehensive resources like the upcoming webinars hosted by the Automotive Repair Association or engaging with authoritative publications such as the SAE Technical Papers collection. The future of transmission diagnostics belongs to those prepared to adopt and adapt advanced technological solutions—are you ready to lead in this transformation?

Revolutionizing Diagnostic Precision with Multisensor Integration

The next leap in transmission troubleshooting hinges on multisensor data fusion, a sophisticated approach where signals from vibration analyzers, thermography, fluid analytics, and electrical sensors coalesce to unveil hidden faults. By employing complex algorithms rooted in signal processing theory, technicians can identify subtle anomalies indicative of early wear or impending failure, significantly reducing repair guesswork and enhancing diagnostic confidence.

This integrative methodology allows for a comprehensive health assessment of transmission systems, ensuring that repairs address root causes rather than symptoms. Such multidimensional data collection, supported by machine learning models trained on vast fault datasets, enhances predictive maintenance capabilities—shifting auto repair from reactive to anticipatory practices.

Harnessing AI and Machine Learning for Predictive Transmission Health Monitoring

Artificial intelligence is transforming transmission diagnostics by enabling real-time predictive analytics. Machine learning algorithms analyze sensor data streams—detecting patterns associated with micro-fractures, lubrication breakdowns, or electronic component degradation. This constant learning process refines fault prediction models, allowing for early intervention before symptoms manifest overtly.

According to SAE International’s recent studies, AI-driven diagnostic systems can cut down troubleshooting time by nearly 50%, while increasing repair accuracy. These advancements empower technicians to schedule targeted interventions, optimize parts inventory, and extend transmission lifespan, ultimately elevating customer satisfaction and operational efficiency.

Is Your Shop Ready for the AI-Driven Diagnostic Future?

Staying ahead requires proactive inclusion of intelligent diagnostics within your service repertoire. Investing in AI-enabled tools, embracing continuous training in data analytics, and collaborating with industry research institutions can position your auto repair establishment as a leader in technological adoption. Engage with datasets, industry reports, and expert webinars to foster a culture of innovation that aligns with the evolving automotive landscape, ensuring your expertise remains unmatched in accuracy and speed.

Precision Calibration as a Foundation for Accurate Diagnostics

Maintaining sensor calibration integrity is crucial for high-fidelity diagnostics. In advanced transmissions, sensors measuring fluid viscosity, temperature, and electrical parameters must be calibrated with OEM precision regularly, considering environmental influences and sensor drift over time. Automated calibration protocols embedded within diagnostic software streamline this process, reducing human error and maintaining systemic reliability.

Inaccurate sensor data can lead to misdiagnoses, unnecessary repairs, or overlooked faults, undermining customer trust. Therefore, establishing routine calibration schedules aligned with industry standards is paramount for sustained diagnostic excellence and fault detection accuracy.

Multi-Point Sensor Verification Enhances Fault Detection Depth

Employing multi-point sensor verification involves cross-referencing data from multiple sources—such as combining thermographic imaging with vibration analysis—to confirm findings before proceeding with repairs. This layered approach catches inconsistencies and isolates complex failure modes, fostering confidence in diagnostic conclusions. Advanced diagnostic workstations incorporating real-time sensor validation are increasingly becoming industry staples, providing technicians with a robust toolkit for complex transmission issues.

Non-Invasive Technologies: Seeing Inside Without Opening Up

Non-invasive inspection tools have become indispensable for early fault detection, minimizing vehicle downtime and preserving component integrity. Thermal imaging identifies hotspots caused by slipping clutches or overheated solenoids, while ultrasonic sensors detect abnormal vibrations indicative of gear contact anomalies. These methods allow rapid, damage-free assessments, guiding more invasive diagnostics only when necessary.

Moreover, infrared thermography offers a window into internal heat dissipation issues, crucial for diagnosing fluid starvation or internal friction problems. Embracing these technologies elevates diagnostic precision and reinforces a shop’s reputation for cutting-edge expertise.

Expert Insights & Advanced Considerations

The Power of Multisensor Data Fusion Enhances Fault Detection

Combining data sources like vibration analysis, thermal imaging, and fluid characteristics leads to more accurate diagnosis, enabling early intervention and reducing unnecessary repairs.

Artificial Intelligence Transforms Predictive Maintenance

Integrating AI and machine learning algorithms allows technicians to anticipate failures with remarkable precision, streamlining repair scheduling and extending transmission lifespan.

Calibrating Sensors for Optimal Results Is Non-Negotiable

Regular, OEM-guided calibration of temperature, viscosity, and electrical sensors maintains diagnostic integrity, preventing errors that could lead to misdiagnosis or missed faults.

Non-Invasive Inspection Tools Elevate Diagnostic Confidence

Thermography, ultrasonic testing, and infrared imaging provide damage-free insights into internal issues, accelerating repairs and safeguarding component health.

Standards and Certifications Drive Industry Excellence

Adherence to ASE and OEM training, coupled with engagement in industry forums like SAE, ensures technicians stay at the forefront of automotive innovation.

Curated Expert Resources

- SAE International Technical Papers: Cutting-edge research on sensor integration and data analysis techniques for next-generation diagnostics.

- Automotive Service Excellence (ASE) Certification: Recognized credentials that validate diagnostic proficiency and commitment to industry standards.

- Industry Conferences (e.g., SAE World Congress): Platforms to explore emerging technologies and network with industry trailblazers.

- Specialized Publications like Autotech Review: In-depth articles on AI, machine learning, and innovative diagnostic equipment shaping the future of auto repair.

- Manufacturer OEM Manuals and Training Modules: Essential resources for calibration protocols and system-specific troubleshooting guidance.

Final Expert Perspective

In the fast-evolving terrain of transmission diagnostics, the synergy of multisensor data fusion, AI-driven predictive analytics, and rigorous calibration protocols forms the cornerstone of exceptional auto repair. Embracing these advanced strategies not only enhances diagnostic accuracy but also positions your shop as a leader in reliability and innovation. Engage with industry-leading resources and commit to continuous mastery—your clients will notice the difference, and your reputation will thrive. How will you incorporate these cutting-edge approaches to redefine excellence in your transmission repairs? Let’s connect and explore the future of vehicle diagnostics together.

This post really highlights the incredible amount of technological advancement in transmission diagnostics. From AI-driven predictive analytics to multisensor data fusion, it’s clear that modern auto repair is more science than traditional mechanics now. I’ve personally started integrating thermal imaging and vibration analysis into my shop, and the difference in early fault detection is significant. It’s fascinating how these tools can uncover issues that would have otherwise gone unnoticed until they became major problems.

One challenge I’ve encountered is the calibration of these sensors over time, which underscores the importance of automated calibration routines. I wonder how others are handling calibration schedules within busy service shops—are there best practices or specific tools that help streamline this? Also, with so much data, how are shops effectively training technicians to interpret multisensor fusion reports accurately? Looking forward to hearing experiences and tips on managing these emerging diagnostic technologies efficiently.