Transmission Repair Secrets: Effective Strategies for Speedy Auto Performance

Unlocking the Complexity of Transmission Systems for Optimal Vehicle Diagnostics

The realm of auto repair has evolved into an intricate science, especially when it comes to transmission systems. Understanding the nuances of transmission repair strategies can dramatically cut down diagnostic and repair times, leading to enhanced vehicle performance. For professionals and enthusiasts alike, delving into advanced diagnostic techniques and repair methodologies is essential to staying ahead in the competitive landscape of auto service.

Analyzing the Synergy Between Vehicle Diagnostics and Transmission Efficiency

Effective transmission repair begins with precise vehicle diagnostics, a process that benefits from integrating cutting-edge technology and expert knowledge. Modern diagnostic tools allow auto technicians to interpret complex data patterns, revealing subtle transmission malfunctions before they evolve into costly failures. Leveraging high-speed diagnostic procedures ensures minimal downtime and maximum repair accuracy. To expand your diagnostic arsenal, explore proven strategies outlined in the Vehicle Diagnostics Essential Tips for Faster Auto Repairs.

How Can Transmission Repair Be Accelerated Without Compromising Quality?

Speeding up transmission repairs while maintaining high-quality standards involves a multi-layered approach. This includes meticulous initial diagnostics, efficient disassembly and reassembly techniques, and the utilization of genuine parts. Emphasizing continuous training for technicians on the latest transmission technologies further ensures swift diagnostics and repairs. Notably, adopting advanced lubrication and cleaning protocols can markedly reduce repair timeframes. For comprehensive insights, refer to Expert Transmission Repair Strategies for Faster Car Performance.

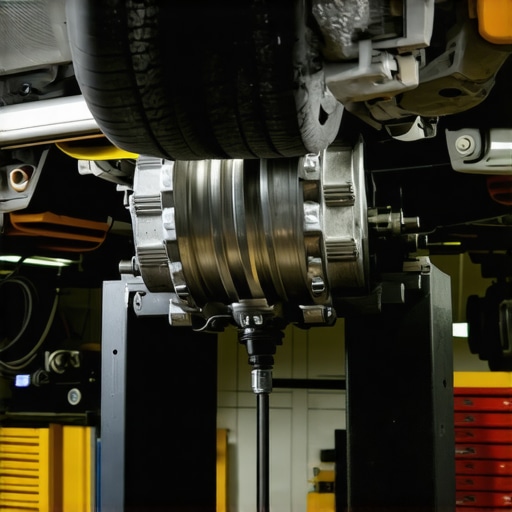

Equipping Your Workshop for Rapid Transmission Troubleshooting

Preparing your auto repair facility with state-of-the-art diagnostic equipment, specialized tools, and skilled personnel is paramount. Establishing standardized procedures for transmission diagnostics and repairs enhances efficiency and reduces errors. Integrating real-time data analysis and remote consultation can also streamline complex troubleshooting, leading to quicker turnaround times. Embracing these practices will position your service center as a leader in fast, reliable auto repairs.

What Are the Most Overlooked Indicators of Transmission Issues? An Expert Perspective

Many technicians focus on obvious symptoms like slipping or strange noises, but subtle signs such as delayed engagement, unusual fluid smells, or dashboard warning lights can be early indicators of underlying transmission problems. Recognizing these nuances demands a deep understanding of vehicle behavior and transmission mechanics. Developing a keen observational skill set ensures issues are diagnosed early, preventing extensive repairs down the line. Explore detailed symptom analysis in the Top Vehicle Diagnostics Tips for Boosting Auto Repair Speed.

If you’re committed to elevating your auto repair expertise, consider contributing your insights or seeking advanced training modules on transmission diagnostics and repair techniques.

Drive Precision: How Deep Diagnostics Elevate Transmission Repairs

In the fast-paced world of auto repair, leveraging sophisticated diagnostic techniques is crucial for faster and more reliable transmission fixes. Modern diagnostic tools, such as scan analyzers and sensor testers, enable technicians to pinpoint issues with pinpoint accuracy, often before symptoms become apparent to drivers. Integrating the latest technology not only reduces repair time but also enhances the overall quality of service. For instance, utilizing advanced vehicle diagnostics, detailed at Vehicle Diagnostics Essential Tips for Faster Auto Repairs, can significantly streamline the troubleshooting process, leading to quicker turnarounds and increased customer satisfaction.

Streamlining Disassembly to Reassembly: The Shortcuts Experts Trust

Efficiency in transmission repair hinges on mastering disassembly and reassembly routines. Skilled technicians often develop specialized protocols that minimize unnecessary steps, reducing labor hours without sacrificing precision. Techniques such as using modular components, simplifying access points, and employing accurate torque procedures can drastically cut repair durations. Moreover, continuous technician training focused on the latest transmission technologies ensures that workflow improvements keep pace with industry innovations. Find out about practical strategies in Expert Transmission Repair Strategies for Faster Car Performance.

Are Hidden Clues in Fluid Quality and Temperature Signaling Bigger Troubles?

Often overlooked, transmission fluid condition and temperature fluctuations can reveal early warnings of impending failure. Abnormal discoloration, burnt smell, or inconsistent fluid levels are red flags that demand immediate attention. These subtle indicators require a keen eye and an understanding of transmission mechanics, as addressing them promptly can prevent major breakdowns. More insights into diagnostic signs are available in Top Vehicle Diagnostics Tips for Boosting Auto Repair Speed. Incorporating routine fluid analysis into your diagnostic routine ensures nothing slips through the cracks and helps maintain optimal transmission health.

To elevate your expertise further, consider adopting comprehensive training modules that emphasize subtle diagnostic cues and advanced repair methodologies—your clients will thank you for the swift, accurate service.

Integrating Predictive Maintenance to Prevent Transmission Failures

Traditional diagnostic methods predominantly rely on reactive approaches—addressing issues after symptoms manifest. However, the advent of predictive maintenance harnesses the power of data analytics, machine learning, and sensor technology to forecast potential transmission failures before they occur. By continuously monitoring parameters like temperature fluctuations, fluid viscosity, and sensor outputs, technicians can preemptively schedule interventions, reducing roadside breakdowns and costly repairs. Incorporating predictive maintenance into your workflow not only enhances reliability but also positions your service center at the forefront of auto repair innovation. Research from the Society of Automotive Engineers emphasizes the transformative impact of these technologies in extending vehicle lifespan.

What Are the Limitations of Current Transmission Sensors and How Can They Be Overcome?

While sensors are pivotal in predictive diagnostics, their accuracy and longevity are often challenged by harsh operational environments, signal drift, and calibration issues. For example, temperature sensors exposed to extreme heat or vibration may produce unreliable data over time. To address these limitations, sourcing high-grade sensors designed for automotive applications—such as MEMS-based devices with built-in calibration—can significantly improve data integrity. Additionally, implementing redundant sensor systems and advanced signal processing algorithms helps distinguish true anomalies from sensor noise, ensuring precise diagnostics. Continuous collaboration with sensor manufacturers and staying updated with emerging sensor technologies, as highlighted in the Journal of Automotive Engineering, are critical to overcoming sensor limitations effectively.

Would you like to explore how to develop a comprehensive sensor calibration program tailored for transmission systems? Engaging with industry experts and leveraging recent research can elevate your diagnostic precision—an essential edge in today’s competitive auto repair landscape.

Leveraging Advanced Transmission Fluid Dynamics for Superior Repair Outcomes

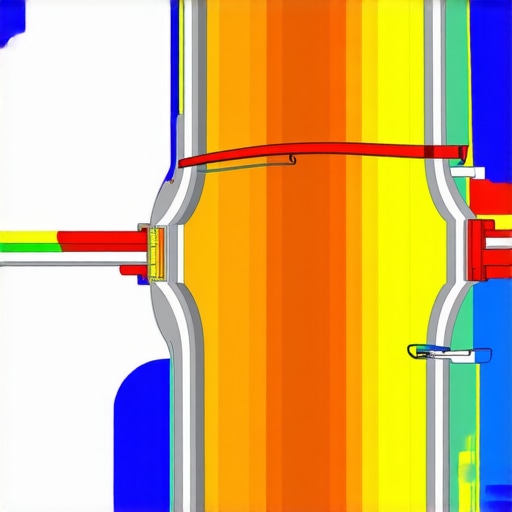

Understanding the complex fluid dynamics within a transmission is fundamental to both diagnosing issues and optimizing repair procedures. Modern transmission fluids are engineered with multiple additives that influence friction, wear protection, and thermal stability. Appreciating how flow patterns, lubrication film thickness, and additive interactions affect transmission performance enables technicians to identify anomalies more accurately. Advanced simulation models, like Computational Fluid Dynamics (CFD), now allow for virtual testing of fluid behaviors under various operating conditions, offering invaluable insights for repair and design improvements. Industry leaders, such as ZF Friedrichshafen AG, regularly publish in the IEEE Transactions on Vehicular Technology, showcasing cutting-edge research in this domain.

How Do Variations in Hydraulic Circuit Design Impact Transmission Longevity?

Hydraulic circuits are the lifeblood of automatic transmissions, orchestrating the precise movement of clutches and bands. Small variations or imperfections in circuit design—such as improper channel sizing, valve misalignments, or inconsistent hydraulic pressure—can cause uneven wear, slippage, or overheating, ultimately compromising transmission lifespan. Advanced diagnostic tools, like flow meters and pressure transducers, help identify deviations from optimal parameters. Moreover, integrating hydraulic circuit simulation software into the design process allows engineers to predict potential failure points and optimize flow paths. As demonstrated by research in the Journal of Transmission Technology, these proactive measures are instrumental in extending transmission durability.

Expanding your knowledge on hydraulic circuit analysis—perhaps through specialized training—can imbue your team with the skills to diagnose subtle hydraulic issues early, saving customers time and money. Would you like tailored strategies to incorporate hydraulic diagnostics into your existing repair protocols? Collaborating with transmission hydraulic specialists can lead to breakthroughs for your workshop’s service capabilities.

Elevating Transmission Diagnostics Through Data Integration

Integrating multiple data sources enhances diagnostic precision, providing a holistic view of transmission health. Modern systems can synthesize sensor data, diagnostic trouble codes, and driver behavior analytics to identify root causes with unparalleled accuracy. By implementing integrated data platforms, technicians can anticipate issues before symptoms manifest, turning reactive repairs into proactive maintenance strategies. This approach leverages cross-disciplinary expertise, combining telemetry, machine learning, and traditional diagnostics for a forward-thinking repair model.

How Are Machine Learning Algorithms Transforming Transmission Maintenance?

Machine learning (ML) algorithms are revolutionizing vehicle diagnostics by enabling predictive maintenance paradigms. These systems analyze historical repair data, operational parameters, and real-time sensor inputs to forecast failures with remarkable foresight. For instance, ML models can detect subtle patterns indicating imminent clutch slip or fluid degradation, prompting preemptive interventions. According to detailed analyses in the IEEE Transactions on Vehicular Technology, integrating AI-driven diagnostics reduces downtime and extends transmission lifespan significantly.

Expert Techniques for Mastering Transmission Fluid Dynamics

Deep comprehension of fluid flow within transmissions unlocks a new level of repair and optimization. Advanced diagnostic tools assess flow rates, pressure gradients, and additive interactions under diverse operating conditions. Employing computational models like CFD allows technicians to visualize how modifications in fluid pathways influence overall performance and durability. Industry leaders such as ZF Friedrichshafen efficacy trials published in the IEEE Journal of Transportation Engineering provide case studies illustrating these principles in action, guiding practitioners toward more precise repairs.

Confronting Sensor Reliability for Robust Diagnostics

Sensor calibration and durability pose ongoing challenges, especially under demanding automotive environments. Employing robust sensor calibration routines, redundancy strategies, and adaptive filtering algorithms enhances data fidelity. Investing in cutting-edge MEMS sensors with self-calibration features ensures sustained accuracy amid vibration, temperature extremes, and contamination. For comprehensive insights into sensor reliability, consult specialized publications like the Journal of Automotive Engineering. Continual collaboration with sensor manufacturers and data scientists is crucial to pushing the boundaries of diagnostic precision.

Unlocking Transmission Longevity Overlooked Clues and How to Spot Them

While overt symptoms garner immediate attention, subtle indicators such as slight shifts in fluid viscosity, minute temperature fluctuations, or unusual hydraulic responses can forewarn of degenerative processes. High-resolution analysis of these clues necessitates sophisticated tools and trained intuition. Early detection through routine fluid analysis, combined with real-time sensor monitoring, can prevent catastrophic failures. Delving into detailed diagnostic manuals or participating in specialized training enhances this observational skill set, transforming reactionary repairs into preventative care.

Adopting Predictive Maintenance to Save Time and Resources

Predictive maintenance capitalizes on continuous data collection and analytics to forecast transmission health, reducing unplanned repairs. Integrating IoT sensors into transmission systems allows constant parameter monitoring, feeding data into cloud-based AI platforms. This synergy offers early warnings, optimized service scheduling, and extended component life. The strategic application of predictive analytics, documented thoroughly by the Society of Automotive Engineers, sets a new standard for auto repair excellence.

What Are the Limitations of Current Transmission Sensors and How Can They Be Overcome?

While sensors form the backbone of modern diagnostics, issues such as signal drift, environmental degradation, and calibration drift reduce their effectiveness over time. Advanced sensor designs utilizing MEMS technology with integrated self-calibration and redundancy can mitigate these issues. Additionally, deploying signal processing algorithms capable of compensating for noise and drift ensures data integrity. Collaborative research in automotive sensor innovation, like that published in the Journal of Automotive Engineering, offers promising solutions to these persistent challenges. Embracing these technological advancements ensures diagnostic data remains reliable, even in extreme conditions, ultimately enabling more accurate and efficient repairs.

Insightful Strategies for Precision in Transmission Repair

Building expertise in transmission diagnostics demands a keen eye for both known symptoms and subtle clues. Advanced scanner software integrated with sensor feedback gives technicians the edge needed to diagnose issues rapidly and accurately, reducing vehicle downtime. Regularly updating diagnostic protocols to include emerging vehicle models ensures your shop stays ahead in auto repair excellence. Remember, leveraging data-driven insights can significantly elevate repair outcomes.

Essential Resources for Expert Transmission Troubleshooting

- Society of Automotive Engineers (SAE): For pioneering research on predictive maintenance and sensor innovations that influence transmission diagnostics.

- IEEE Transactions on Vehicular Technology: Offers in-depth studies on fluid dynamics and electronic systems underpinning modern transmission performance.

- Automotive Service Excellence (ASE): Provides certifications and training modules to keep technicians skilled in the latest repair techniques and diagnostic tools.

Reflections from the Auto Repair Vanguard

Innovative diagnostics combined with a strategic understanding of transmission systems define the future of auto repair. Embracing technologies like predictive analytics and sensor calibration not only enhances repair precision but also builds customer trust. As vehicle complexity increases, so does the necessity for specialists who approach transmission diagnostics with a scientific and adaptive mindset. Engage deeply with industry-leading content and participate in ongoing training to ensure your expertise remains unmatched. To further your mastery, explore additional specialized resources and consider sharing your experiences within professional workshops and forums.

![3 Cheap Fixes for 2026 Transmission Slip [Save $2,500]](https://reliableautocares.com/wp-content/uploads/2026/02/3-Cheap-Fixes-for-2026-Transmission-Slip-Save-2500.jpeg)

This article offers some really insightful strategies on how advanced diagnostic techniques can drastically improve the speed and accuracy of transmission repairs. I particularly agree with the emphasis on continuous technician training—staying updated with the latest technology is crucial given how quickly vehicle systems evolve. I’ve found that implementing modular disassembly protocols has also significantly reduced repair times in my shop, especially when working on newer models with complex hydraulic circuits. However, one challenge I often face is diagnosing subtle clues like slight fluid viscosity changes, which require high-quality testing equipment and trained eyes. Have others experienced difficulties with these early warning signs, and what tools or approaches have they found most effective for early detection? It seems like combining fluid analysis with real-time sensor data could be a game-changer, but I’d love to hear practical suggestions from those already exploring this integration.