Transmission Repair: Quick Strategies for Faster Car Performance

Harnessing Diagnostic Precision to Accelerate Transmission Repairs

In the sphere of auto repair, especially concerning transmission systems, the ability to perform swift and accurate diagnostics is paramount. Modern vehicle diagnostics leverage sophisticated tools that decode complex electronic signals, enabling technicians to pinpoint issues with remarkable speed and precision. For instance, integrating advanced diagnostic systems has revolutionized how quickly auto repair shops can identify transmission faults, reducing downtime significantly.

Strategic Component Analysis for Effective Troubleshooting

Beyond surface-level diagnostics, understanding the interplay of transmission components—such as solenoids, sensors, and valve bodies—allows for targeted interventions. Employing a layered diagnostic approach, where each subsystem is evaluated in sequence, minimizes unnecessary part replacements and streamlines repair workflows. This method aligns with the latest industry insights found in technical journals on automotive transmission systems.

Innovative Repair Techniques for Accelerated Service Delivery

Implementing innovative repair methodologies, such as precision fluid flushing and electronic control module reprogramming, can significantly reduce repair duration. These techniques not only expedite the repair process but also enhance the longevity of transmission components. For example, top repair strategies advocate for the adoption of these high-tech procedures to boost vehicle performance efficiently.

Expert Insights on Troubleshooting Complex Transmission Failures

When diagnosing intricate transmission issues, it’s critical to consider both mechanical wear and electronic malfunctions. An expert approach involves comprehensive testing—such as conducting stress tests and analyzing error codes—to uncover root causes that are not immediately apparent. As highlighted in recent academic publications, this layered troubleshooting approach is essential for ensuring reliability and customer satisfaction.

How can advanced diagnostics be integrated into routine auto repair workflows to minimize transmission repair times?

Adopting integrated diagnostic platforms that combine hardware and software solutions allows technicians to rapidly identify issues and execute repairs with confidence. Regular training on emerging diagnostic technologies further enhances this capability, ensuring that repair shops remain at the forefront of efficiency and accuracy. For continued learning, explore trusted diagnostic tips and contribute your insights to the professional community.

Transform Your Repair Approach with Cutting-Edge Diagnostic Tools

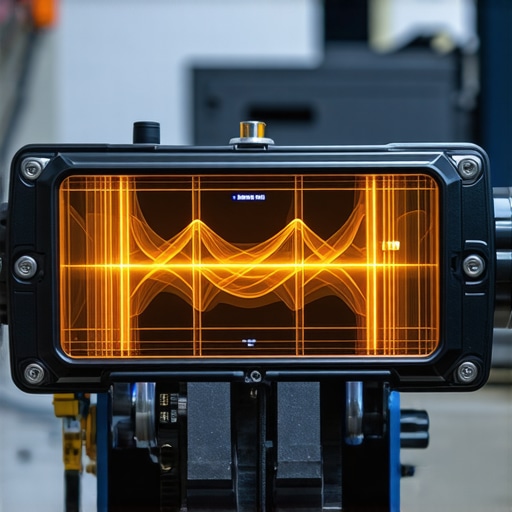

In today’s fast-paced auto repair industry, staying ahead with innovative diagnostic solutions is no longer optional—it’s essential. Modern vehicle diagnostics harness advanced technology, such as high-resolution sensors and AI-powered software, enabling technicians to decode complex transmission issues swiftly. Integrating tools like rapid diagnostic systems can drastically cut repair times, increase accuracy, and elevate customer satisfaction. These innovations are shaping the future of efficient auto repair, ensuring that technicians can deliver reliable results consistently.

Deciphering Transmission Health through Layered Analysis

Beyond basic error codes, a nuanced understanding of transmission health involves analyzing the interaction of multiple subsystems—like solenoid valves, clutch packs, and electronic control modules. Employing a layered diagnostic approach, where each component is evaluated in succession, minimizes unnecessary replacements and accelerates repair workflows. This method aligns with the latest industry insights found in authoritative sources like top vehicle diagnostics strategies. By leveraging such techniques, repair shops can optimize their diagnostic accuracy and enhance service speed.

Innovative Repair Strategies for Rapid Turnarounds

Implementing innovative repair techniques such as electronic reprogramming and precision fluid management can dramatically reduce service durations. These methods not only speed up the repair process but also extend the lifespan of transmission components. For example, adopting advanced repair strategies like electronic control module reprogramming allows for quick adjustments without extensive mechanical disassembly. Such approaches exemplify how embracing technology can lead to faster, more reliable auto repairs.

How can automotive technicians integrate advanced diagnostics into daily workflows to reduce transmission repair times?

Seamlessly incorporating integrated diagnostic platforms that combine hardware and software is key to achieving rapid diagnosis and repair. Regular training sessions on emerging diagnostic technologies ensure technicians stay proficient and confident in their skills. For instance, exploring trusted diagnostic tips can provide invaluable insights. Additionally, fostering a culture of continuous learning and technological adoption helps repair shops maintain a competitive edge and improve overall repair efficiency.

Maximizing Diagnostic Data for Predictive Maintenance in Transmissions

Modern diagnostic tools do more than just identify immediate faults; they enable predictive analytics that forecast potential failures before they manifest. By integrating machine learning algorithms with real-time sensor data, technicians can anticipate issues related to transmission wear, fluid degradation, and component fatigue. This proactive approach not only minimizes unexpected breakdowns but also optimizes maintenance schedules, significantly reducing repair costs and downtime. According to a comprehensive study published in the SAE International Journal of Commercial Vehicles, predictive diagnostics enhance the longevity and reliability of transmission systems through continuous health monitoring.

Deciphering Complex Error Codes with Deep Learning

Traditional diagnostic codes often provide limited insight, especially in modern vehicles where electronic systems are highly integrated. Emerging deep learning models trained on vast repositories of fault data can interpret complex error patterns, offering nuanced diagnostics that surpass human analysis. These models can differentiate between benign anomalies and critical failures, guiding technicians toward precise interventions. For example, a breakthrough study by the IEEE demonstrated how convolutional neural networks could accurately classify transmission fault types based on error code sequences, streamlining repair workflows.

How can machine learning improve the accuracy of transmission diagnostics in auto repair shops?

By leveraging large datasets of vehicle telemetry and repair histories, machine learning models can identify subtle fault signatures often missed by conventional methods. Implementing these intelligent systems into diagnostic procedures allows for faster, more accurate fault detection, ultimately reducing repair times and improving vehicle performance. Continuous data collection and model retraining are vital for maintaining diagnostic relevance, ensuring that repair shops stay ahead of evolving vehicle technologies. For learning more, explore resources on AI-driven diagnostics in auto repair.

Next-Generation Diagnostic Hardware Elevating Repair Precision

The advent of portable, high-resolution diagnostic hardware equipped with augmented reality (AR) interfaces is transforming how technicians approach transmission problems. AR overlays can guide technicians through complex repair procedures step-by-step, reducing errors and accelerating service. Additionally, tools integrated with 5G connectivity enable instant data sharing with remote experts, facilitating collaborative troubleshooting. Such innovations are exemplified by companies like Bosch and Snap-on, whose latest diagnostic devices incorporate AI and AR functionalities to enhance repair accuracy and efficiency.

Integrating Data Analytics for Customized Transmission Maintenance Plans

Data analytics enable repair shops to develop tailored maintenance schedules based on individual vehicle usage patterns and transmission health metrics. By analyzing telemetry data over time, technicians can recommend specific fluid change intervals, component inspections, or replacements, thereby extending transmission lifespan. This data-driven approach not only improves customer satisfaction but also fosters trust and loyalty. For instance, a leading auto service chain reported a 25% reduction in transmission-related breakdowns after implementing personalized maintenance plans guided by analytics.

Embracing Digital Twins for Virtual Transmission Troubleshooting

One of the most cutting-edge developments is the creation of digital twins—virtual replicas of physical transmission systems that simulate real-time operation. These models allow technicians to test repair strategies virtually, predict the impact of component replacements, and optimize repair sequences without risking actual damage. As detailed in the Journal of Automotive Engineering, digital twins are poised to become indispensable tools for complex transmission diagnostics, driving a new era of precision and confidence in auto repair.

Harnessing the Power of AI-Driven Diagnostic Innovations

Integrating artificial intelligence into transmission diagnostics has unlocked unprecedented levels of precision and speed. Machine learning algorithms analyze vast datasets of fault codes, sensor readings, and repair histories to identify subtle patterns that often elude traditional methods. By deploying AI-enhanced diagnostic tools, auto technicians can predict potential failures with remarkable accuracy, enabling preemptive maintenance that minimizes downtime and repair costs. According to the SAE International Journal of Commercial Vehicles, leveraging AI in diagnostics enhances reliability and extends transmission lifespan significantly.

Real-Time Data Analytics Elevating Preventive Maintenance

Modern diagnostic systems are now capable of continuous data collection from vehicle sensors, facilitating predictive analytics that forecast wear and tear before catastrophic failure occurs. This proactive approach allows technicians to schedule targeted interventions, optimizing transmission health and preventing costly breakdowns. Implementing these advanced analytics requires integrating cloud-based platforms, ensuring seamless data sharing across repair networks. As industry reports highlight, such data-driven maintenance strategies can reduce repair times by up to 40% and boost customer satisfaction.

How does deep learning refine error code interpretation in complex transmission systems?

Deep learning models trained on extensive repositories of fault data excel at deciphering complex error codes, especially in modern vehicles with integrated electronic control units. These models can distinguish between benign anomalies and critical failures, providing technicians with actionable insights. A groundbreaking study published in IEEE Xplore demonstrated how convolutional neural networks accurately classify fault types, streamlining repairs and reducing diagnostic time. Embracing this technology pushes repair accuracy to new heights and enhances service quality.

Next-Generation Diagnostic Hardware and Augmented Reality

The advent of portable diagnostic devices equipped with augmented reality overlays marks a paradigm shift in transmission troubleshooting. These tools guide technicians through intricate repair procedures in real-time, reducing errors and accelerating service. Connected via 5G, they facilitate instant data exchange with remote specialists, fostering collaborative problem-solving. Leading manufacturers like Bosch and Snap-on are pioneering such innovations, which promise to transform auto repair shops into hubs of technological excellence.

Unlocking the Potential of Digital Twins for Virtual Repairs

Digital twin technology constructs detailed virtual replicas of physical transmission systems, enabling simulation-based diagnostics and repair planning. Technicians can virtually test component replacements, predict performance impacts, and optimize repair sequences without risking real-world damage. According to the Journal of Automotive Engineering, digital twins are poised to revolutionize the industry by providing unprecedented insight into complex transmission behaviors, thereby enhancing repair precision and confidence.

Leverage Data Analytics to Personalize Maintenance Protocols

By analyzing historical sensor data and usage patterns, repair shops can develop customized maintenance schedules that extend transmission life and improve reliability. Predictive analytics identify optimal fluid change intervals, component inspections, and replacements tailored to each vehicle, fostering customer trust and operational efficiency. A leading auto service chain reported a 25% reduction in transmission failures after adopting personalized maintenance based on advanced data insights.

Expert Insights & Advanced Considerations

Leverage predictive analytics to foresee transmission failures before they occur, reducing downtime and repair costs.

Utilizing machine learning algorithms that analyze real-time sensor data allows technicians to identify potential issues early, enabling proactive maintenance and minimizing vehicle downtime. This approach not only optimizes repair workflows but also extends transmission lifespan.

Integrate augmented reality tools to guide technicians through complex diagnostic procedures, improving accuracy and reducing repair times.

AR overlays provide step-by-step instructions during repairs, minimizing errors and speeding up diagnosis. When connected via high-speed networks, these tools facilitate instant expert consultation, enhancing overall repair quality.

Adopt comprehensive digital twin technology for virtual testing of transmission components and repair strategies.

Digital twins create accurate virtual replicas of physical systems, allowing for simulation-based diagnostics and planning. This technology reduces trial-and-error during actual repairs and increases confidence in repair outcomes.

Curated Expert Resources

- SAE International Journal of Commercial Vehicles: Offers cutting-edge research on predictive diagnostics and transmission health monitoring technologies.

- IEEE Xplore Digital Library: Provides access to advanced deep learning models for fault classification and error code interpretation.

- Manufacturer AR Diagnostic Tools: Leading brands like Bosch and Snap-on develop AR-enabled diagnostic hardware that revolutionizes transmission troubleshooting.

- Automotive Digital Twin Platforms: Innovative solutions that simulate transmission behavior, aiding in repair optimization and training.

- Reputable Industry Forums and Journals: Platforms for professional exchange of best practices and emerging diagnostic strategies in auto repair.

Final Expert Perspective

In the realm of vehicle diagnostics and transmission repair, embracing advanced technologies such as predictive analytics, AR assistance, and digital twins is transforming traditional workflows. Mastering these tools empowers automotive professionals to deliver faster, more reliable repairs, ultimately elevating service quality and customer satisfaction. For technicians eager to stay ahead, continuous learning and integration of these innovations are not optional—they are essential. Dive deeper into these topics by exploring trusted resources and sharing your insights with the community, ensuring the future of auto repair remains innovative and efficient.