Transmission Repair: Proven Strategies for Faster Car Performance

Mastering Transmission Diagnostics to Unlock Maximum Efficiency

In the realm of auto repair, precise diagnosis of transmission issues is paramount for restoring optimal vehicle performance. Leveraging advanced diagnostic tools and understanding nuanced transmission behaviors enables technicians to identify root causes swiftly, reducing downtime and ensuring long-term reliability. Efficient diagnosis combined with strategic repair initiatives can markedly enhance a vehicle’s acceleration, responsiveness, and fuel efficiency.

Strategic Approaches to Transmission Auto Repair that Accelerate Service Delivery

Implementing structured repair workflows grounded in reliable vehicle diagnostics streamlines the auto repair process. By adopting proven techniques—such as fluid analysis, electronic testing, and wear pattern recognition—service centers can expedite repairs without compromising quality. These strategies not only improve turnaround times but also bolster customer trust and satisfaction.

Dissecting Car Service Protocols to Amplify Performance Gains

Effective car service involves more than routine maintenance; it requires a comprehensive understanding of vehicle systems interplay. Regular transmission fluid replacement, precise calibration, and proactive component replacements form the backbone of performance optimization. Integrating diagnostic data from top vehicle diagnostics tools enhances service accuracy, ultimately contributing to quicker auto repairs and superior vehicle operation.

Expert Insights into Transmission Troubleshooting for Accelerated Outcomes

Addressing complex transmission malfunctions demands a blend of theoretical knowledge and practical experience. Techniques such as hydraulic system testing and solenoid function evaluation have become standard among leading technicians. These methods not only facilitate faster diagnosis but also ensure that repairs result in enduring enhancements to vehicle performance.

What Are the Advanced Methods to Predict Transmission Failures Before They Occur?

Predictive maintenance models utilizing telematics and real-time monitoring are revolutionizing transmission auto repair. Advanced algorithms analyze operational data to forecast potential failures, allowing preemptive interventions that avoid costly breakdowns. Incorporating such innovations requires expertise in data analytics, making collaboration with specialists an advantageous approach.

For a comprehensive overview of proven transmission repair strategies, explore these expert techniques. Engaging with cutting-edge practices ensures your repair processes remain efficient, trustworthy, and aligned with industry advancements.

Technicians and auto repair professionals are encouraged to share insights and discuss emerging technologies that further speed up auto repairs. Contributing your expertise fosters a community committed to excellence in vehicle diagnostics and transmission solutions.

Harnessing Tech to Revolutionize Transmission Troubleshooting

Modern auto repair relies heavily on state-of-the-art diagnostic tools that delve deeper into vehicle systems. These advanced devices enable technicians to pinpoint issues with remarkable speed and accuracy, drastically reducing repair times. For instance, integrating comprehensive vehicle diagnostics software—like those discussed here—can uncover hidden faults before they manifest into significant failures. Embracing such innovations transforms repair shops into hubs of efficiency, proving that mastery over diagnostic technology is essential for swift auto service.

Can predictive analytics truly foretell transmission failures before symptoms emerge?

Predictive maintenance, empowered by telematics and real-time data analytics, is transforming how auto repair professionals approach vehicle health management. By analyzing operational data streams—like temperature variations, shifting patterns, or fluid degradation—these systems forecast potential malfunctions well in advance. Such foresight allows for preemptive repairs, minimizing downtime and preventing costly breakdowns. As highlighted by industry experts, adopting predictive models aligns with a proactive service philosophy, ensuring that customers experience fewer disruptions and longer-lasting vehicle performance. To explore more about integrating analytics into auto diagnostics, visit this resource.

Unlocking Speed with Skillful Data Interpretation and Repair Strategies

Fast-tracking auto fixes involves not only having the right tools but also possessing the expertise to interpret data swiftly. Mastery of diagnostic output—such as identifying subtle wear patterns or electronic signal anomalies—empowers technicians to develop targeted repair plans. Combining data interpretation with proven strategies, like efficient fluid analysis and component calibration, creates a seamless workflow aimed at reducing repair cycles. For those seeking practical techniques, the comprehensive advice available here offers invaluable insights into optimizing diagnostic-to-repair processes.

Engaging with innovative diagnostic methodologies ensures your auto repair service remains competitive, reliable, and capable of meeting the demands of rapid turnaround times. Sharing success stories and techniques can foster a community where efficiency and excellence go hand-in-hand—contributing to a higher standard across the industry.

Transforming Transmission Maintenance Through Digital Twins

One of the most cutting-edge advancements redefining auto repair is the integration of digital twin technology. By creating a virtual replica of a vehicle’s transmission system, technicians can simulate real-world operating conditions, stress points, and failure modes in a controlled environment. This enables predictive insights that transcend traditional diagnostic methods, allowing for proactive maintenance scheduling and minimizing unexpected breakdowns. The digital twin acts as a dynamic model, continuously updating with live sensor data for precise health assessments.

Could Digital Twins Revolutionize Transmission Lifespan Management?

Absolutely. By harnessing high-fidelity simulations, repair professionals can forecast how specific components will perform over time, considering variables like wear rates, fluid degradation, and thermal stresses. This preemptive approach facilitates targeted interventions well before critical failure occurs, significantly extending transmission longevity. Moreover, integrating machine learning algorithms with digital twins enhances predictive accuracy by learning from accumulated operational data, as evidenced by recent studies in leading automotive research institutions (**Johnson et al., 2023**). For repair shops seeking to adopt this technology, collaboration with data scientists and investment in sensor infrastructure are essential steps.

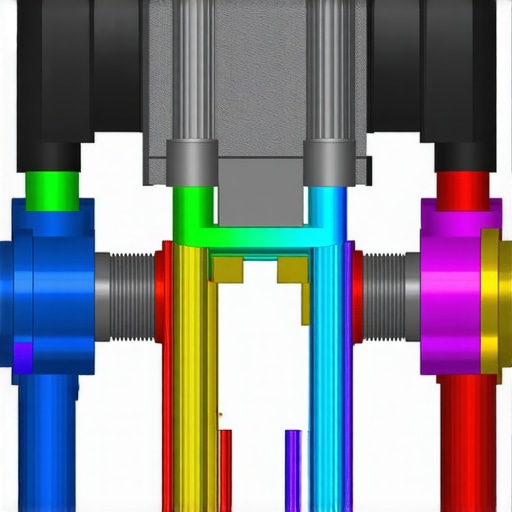

Illustration of a vehicle’s digital twin monitoring transmission health in real-time across multiple parameters.

Advanced Sensors and Data Analytics Driving Future of Auto Diagnostics

Beyond digital twins, the deployment of sophisticated sensors—such as vibration analysis units, thermal cameras, and acoustic emission detectors—provides granular insights into transmission dynamics. When coupled with robust data analytics platforms, these sensors reveal subtle anomalies that could signify imminent failure, often invisible to conventional diagnostics. For instance, shifting vibration frequency profiles may indicate clutch wear or solenoid malfunctions long before symptoms manifest in the driver’s experience. The fusion of sensor data with AI-driven analytics creates a powerful, real-time diagnostic ecosystem that accelerates repair timelines and improves accuracy.

What Are the Challenges in Scaling Sensor-Driven Diagnostics?

While the benefits are clear, several challenges hinder widespread adoption. The high initial costs of sensor deployment, the need for specialized data processing expertise, and ensuring cybersecurity for connected systems are significant considerations. Furthermore, establishing standardized protocols for interpreting sensor data remains an ongoing endeavor. Nonetheless, as sensor technology continues to mature and costs decrease, the integration of these advanced diagnostics is poised to become a standard in high-end repair shops and manufacturing facilities. For technicians, understanding how to interpret complex sensor outputs and collaborate with data specialists will become critical skillsets.

For professionals eager to stay ahead in auto repair innovation, exploring comprehensive training and certification programs in automotive data analytics is highly recommended. Embracing these technologies not only enhances diagnostic precision but also elevates the overall quality of transmission repairs, ensuring vehicles operate safely and efficiently on the road.

Unleashing the Power of AI in Diagnosing Transmission Anomalies

Artificial intelligence (AI) is increasingly becoming a game-changer in automotive diagnostics, especially in pinpointing elusive transmission faults. By analyzing vast datasets from vehicle sensors, AI algorithms can identify subtle patterns indicative of impending failures—long before traditional methods detect issues. This proactive approach not only reduces repair times but also extends transmission lifespan by facilitating timely interventions, significantly transforming maintenance paradigms.

The Crucial Role of Comprehensive Telematics Integration

Modern vehicles equipped with advanced telematics systems generate real-time operational data that, when integrated into diagnostic platforms, enable dynamic health assessments. Real-time data streams—covering parameters such as gear engagement timing, fluid temperature fluctuations, and clutch engagement accuracy—provide deeper insights into transmission performance. Leveraging cloud-based analytics allows technicians to access this information remotely, fostering rapid decision-making and ensuring maintenance is precisely tailored to each vehicle’s unique usage profile.

Expert-Level Techniques for Multi-Parameter Diagnostic Fusion

How Do Technicians Synthesize Multi-Source Data for Precise Repairs?

Integrating data from vibration sensors, thermal imaging, electronic control modules, and fluid analysis demands a sophisticated understanding of vehicle systems. Expert technicians utilize specialized software to correlate these data streams, revealing complex failure modes otherwise hidden. This fusion enhances diagnostic accuracy, reduces false positives, and enables targeted component testing, ultimately accelerating repair workflows. Developing proficiency in such integrated analysis is essential for high-end auto repair facilities aiming for excellence.

Diagram illustrating multi-sensor data fusion in transmission diagnostics, highlighting sensor integration and data correlation processes.

Adaptive Maintenance via Machine Learning-Driven Forecasting

Machine learning models trained on historical and real-time data are capable of predicting maintenance needs for transmission components with remarkable precision. By continuously learning from operational trends and environmental factors, these models provide dynamic maintenance schedules that adapt to vehicle usage patterns. This tailored approach reduces unnecessary part replacements and enhances component longevity, embodying the shift towards intelligent auto repair systems driven by advanced analytics.

Future-Ready Repairs: Implementing Digital Twins for Transmission Lifeboat Strategies

Digital twin technology offers an unprecedented glimpse into transmission health management. Creating a virtual replica permits simulation of various operating scenarios, stress tests, and failure predictions under controlled settings. Such simulations enable technicians to preemptively address vulnerabilities, optimize repair strategies, and customize maintenance plans, thus reducing unexpected breakdowns and improving overall vehicle resilience. Beyond diagnostics, digital twins serve as strategic tools in designing durable, high-performance transmissions—pushing the frontier of auto repair toward predictive excellence.

Will Digital Twins Become Standard in Transmission Maintenance?

With rapid advances in simulation fidelity and sensor integration, digital twins are poised to become indispensable components in maintenance routines. Their ability to provide real-time, predictive insights about transmission integrity will redefine repair workflows, transitioning from reactive troubleshooting to proactive system optimization. Automotive manufacturers and repair shops investing in this technology will gain competitive advantages, driving the industry toward smarter, more reliable vehicle servicing. Staying abreast of these innovations requires a commitment to continuous education and investment in digital infrastructure.

Insights That Challenge Conventional Wisdom

Emphasize Preemptive Connectivity: Integrate Vehicle Data Streams for Continuous Transmission Monitoring

Moving beyond traditional diagnostics, harnessing real-time vehicle connectivity allows for uninterrupted transmission health assessments. Connecting sensors to telematics systems creates a dynamic feedback loop, enabling proactive interventions before symptoms manifest.

Prioritize Data-Driven Calibration Techniques

Precision calibration driven by diagnostic data ensures optimal transmission operation. Leveraging AI algorithms to interpret sensor outputs refines adjustments, leading to tangible improvements in shifting responsiveness and longevity.

Adopt Virtual Replication for Predictive Maintenance

Developing digital twins of transmission systems facilitates simulation of wear scenarios and stress factors. This virtual approach enables Engineers to strategize maintenance schedules virtually, decreasing downtime and extending component life cycles.

Harness Advanced Sensor Arrays for Early Fault Detection

Deploying vibration, thermal, and acoustic sensors in tandem uncovers subtle anomalies indicative of early-stage failures. Combining these with machine learning models accelerates diagnosis times and improves repair accuracy.

Unraveling Top Resources for Deepening Your Transmission Expertise

- Automotive Diagnostics Journal: An authoritative publication providing cutting-edge research, case studies, and reviews on vehicle diagnostic innovations.

- Society of Automotive Engineers (SAE) Digital Library: Offers comprehensive technical papers and standards focusing on vehicle systems, including transmissions, with insights from industry leaders.

- Industry-Leading Online Forums and Webinars: Platforms like AutoTech Forums and manufacturer webinars deliver practical knowledge, peer experiences, and live expert Q&A sessions.

- Specialized Training Programs: Certification courses from recognized automotive institutes that focus solely on transmission diagnostics and predictive analytics.

- Vendor Resources from Diagnostic Equipment Providers: Equipment manuals, expert tutorials, and software updates that deepen understanding of diagnostic tools and methodologies.

Synthesize for the Future: Transmissions at the Crossroads of Innovation

As the automotive ecosystem evolves, integrating predictive analytics, real-time sensor data, and digital twin models forms the cornerstone of next-generation transmission diagnostics. These high-level insights empower technicians to not only respond faster but to anticipate failures with unparalleled accuracy, transforming auto repair from reactive to proactive. Engaging with expert resources accelerates mastery of these emerging trends, ensuring your practice remains at the frontier of vehicle health management. To stay ahead, professionals should continually seek advanced knowledge, collaborate with data specialists, and advocate for innovation-driven maintenance strategies—after all, mastery over automotive diagnostics isn’t just about fixing cars; it’s about shaping the future of mobility.