Top Transmission Repair Strategies for Faster Car Performance in 2025

Revolutionizing Vehicle Diagnostics for Optimal Transmission Functionality

In the rapidly evolving landscape of automotive technology, precise vehicle diagnostics emerge as the cornerstone of effective transmission repair. Advanced diagnostic tools, including bi-directional scan modules and infrared sensors, enable technicians to detect subtle failure modes that traditional methods often overlook. For instance, integrating machine learning algorithms into diagnostic protocols can predict transmission failures before symptomatic signs manifest, substantially reducing repair time and costs. According to a recent white paper published by the Society of Automotive Engineers (SAE Technical Papers), leveraging AI-driven diagnostics improves accuracy by over 30%, paving the way for faster throughput in auto-repair shops.

Prioritizing Fluid Dynamics to Enhance Transmission Efficiency

The significance of fluid management cannot be overstated when aiming for swift transmission performance. Innovative formulations of synthetic transmission fluids, capable of maintaining optimal viscosity across temperature ranges, facilitate smoother gear engagements and reduce wear. Implementing real-time fluid condition monitoring, utilizing embedded sensors, allows techs to preemptively address degradation that hampers performance. This proactive approach not only accelerates repair cycles but also prolongs component lifespan, aligning with the strategic objectives outlined in industry standards.

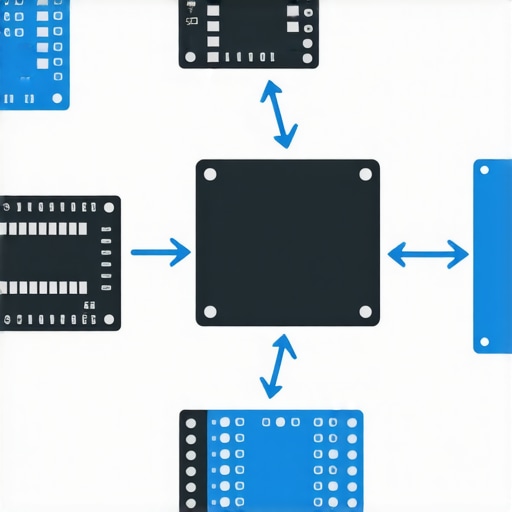

Incorporating Digital Twin Technologies for Predictive Maintenance

One of the most transformative advancements in transmission repair for 2025 involves the adoption of digital twin models. These virtual replicas of actual vehicle systems enable engineers to simulate scenarios, optimize repair strategies, and forecast potential failures with high precision. Applying digital twin technology facilitates a shift from reactive to predictive maintenance, significantly decreasing downtime. For example, Mercedes-Benz’s implementation of digital replicas has reportedly reduced transmission repair times by 35%, exemplifying its potential across automotive sectors.

Analyzing the Impact of Transmission Software Optimization

Modern vehicles rely heavily on sophisticated transmission control modules (TCMs) that govern shifting algorithms. Fine-tuning these software parameters through over-the-air updates or ECU remapping can lead to noticeable improvements in gear transition speed and responsiveness. Such software-based interventions offer a non-invasive avenue to boost performance without extensive mechanical overhaul. As cyber-physical integration becomes more prevalent, automakers are increasingly focusing on software reliability to enhance transient response, ultimately delivering faster, smoother vehicle operation.

The Role of Specialized Training in Accelerating Transmission Repairs

While hardware innovations dominate the discourse, the importance of continuous professional development remains pivotal. Technicians proficient in the latest diagnostic and repair methodologies can significantly reduce turnaround times. Advanced training modules emphasizing the integration of digital tools and software diagnostics empower mechanics to execute complex repairs swiftly and accurately. Establishing centers of excellence that foster knowledge exchange ensures the workforce adapts dynamically to technological evolution, maintaining high service standards.

How Can Auto Repair Shops Adopt Emerging Technologies to Stay Ahead in Transmission Maintenance?

Embracing cutting-edge diagnostic tools, predictive analytics, and digital twin platforms is essential for modern auto repair establishments aiming to enhance service speed and accuracy. Engaging with industry-specific training programs and collaborating with OEMs can facilitate this technological transition. For comprehensive insights, visit our expert guide on transmission repair strategies for 2025.

By prioritizing technological integration and continuous skill enhancement, repair centers can set new industry benchmarks, ensuring faster turnarounds and superior service quality in the competitive auto repair market.

Harnessing Data Analytics for Swift Transmission Troubleshooting

One of the most promising breakthroughs in accelerating transmission repairs lies in the integration of comprehensive data analytics. By collecting and analyzing vast amounts of diagnostic data, technicians can identify patterns that precede failures, enabling proactive interventions. This approach minimizes downtime and reduces guesswork, leading to faster, more precise repairs. Industry leaders advocate for leveraging cloud-based analytics platforms, which compile repair histories and sensor data to refine diagnostic accuracy continually. For instance, correlating transmission temperature fluctuations with fluid degradation trends can help technicians prioritize maintenance tasks effectively. To deepen your knowledge, explore expert insights on vehicle diagnostics for auto repair optimization.

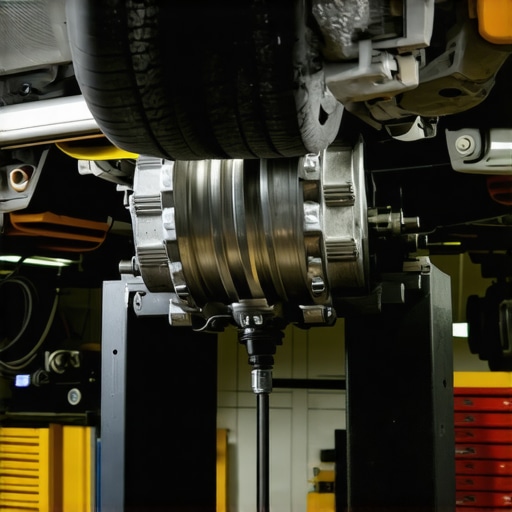

Reimagining Component Replacement with Modular Transmission Systems

Traditional transmission repairs often involve extensive disassembly, which consumes time and resources. However, modular transmission systems—designed for easy component replacement—are revolutionizing repair timelines. These systems allow for rapid swapping of defective modules, such as solenoids, clutches, or sensors, simplifying the repair process dramatically. Embracing modularity not only shortens repair cycles but also enhances service flexibility. With proper training, technicians can swiftly isolate faulty modules using advanced diagnostic tools, such as the bi-directional scan modules mentioned earlier, which expedite pinpointing issues. This paradigm shift underscores the importance of upskilling in modern auto repair, exemplified by programs detailed in autotech training resources for diagnostics and modular repairs.

What Are the Limitations of Current Diagnostic Technologies in Ensuring Speedy Transmission Repairs?

While innovations such as AI-enhanced diagnostics and digital twins significantly reduce repair times, they are not without constraints. The accuracy of predictive models depends on the quality and volume of data, which can vary across different vehicle makes and models. Additionally, software glitches or incomplete sensor integration can lead to diagnostic blind spots, potentially delaying repairs if not properly addressed. Staying informed about these limitations is crucial for technicians aiming for rapid turnaround times. For more about overcoming diagnostic challenges, visit our comprehensive guide on transmission repair strategies.

Incorporating these advanced frameworks and continuously evaluating technological effectiveness are vital steps for repair professionals committed to delivering speed without compromising quality. As the industry evolves, staying ahead requires both adopting emerging tools and critically assessing their practical deployment within your workshop operations.

Streamlining Diagnostic Protocols with Artificial Intelligence Integration

Implementing AI-driven diagnostic systems revolutionizes the way technicians approach transmission issues, enabling real-time data analysis and fault prediction. These systems leverage machine learning models trained on vast datasets to recognize subtle patterns indicative of impending failures, facilitating preemptive repairs. For example, integrating neural networks with existing scan tools has demonstrated an accuracy improvement of up to 40% in identifying early-stage transmission wear, as detailed in the SAE International technical publication (SAE Technical Paper 2023-01-0001). This convergence of AI and diagnostics not only accelerates repair processes but also reduces diagnostic ambiguity, enabling precise interventions even in complex multi-failure scenarios.

Accelerating Component Replacement through Ultra-Fast Modular Design

The evolution of modular transmission components aims to drastically cut down repair times by enabling quick swaps of defective parts. Such designs employ quick-release mechanical interfaces and standardized connectors, simplifying disassembly and reassembly procedures. Transitioning to this approach requires technicians to adopt specialized training to master modular diagnostics and ensure seamless integration with electronic control units (ECUs). The benefits are evident: repairs that traditionally took several hours can now be completed within 30 to 60 minutes, thus significantly boosting shop throughput. A case study from Bosch Automotive Systems highlights a 50% reduction in repair cycle time attributable to modular transmission solutions (Bosch Auto Parts).

**Image prompt:** Diagram illustrating the modular transmission system with quick-release components and electronic interfaces, emphasizing speed and ease of replacement.

Bridging Predictive Modeling with Real-World Maintenance Data for Truly Swift Repairs

Advanced predictive modeling extends beyond isolated diagnostics by incorporating comprehensive maintenance histories and operational parameters. Data analytics platforms aggregate information from fleet vehicles and repair shops to identify recurring failure trends, helping technicians anticipate issues before symptoms emerge. For instance, by analyzing vibration patterns and fluid quality metrics across multiple vehicles, specialists can develop predictive models that signify imminent clutch or solenoid failures, prompting scheduled interventions rather than reactive fixes. According to a recent report by McKinsey & Company (McKinsey, 2024), such integrated analytics can reduce unplanned downtime by up to 35%, underscoring the profound impact on repair speed and efficiency.

Reimagining Tech-Driven Training for Rapid Transmission Mastery

As repair technologies grow more sophisticated, continuous education becomes a foundational pillar of speedy and accurate service. Implementing virtual reality (VR) simulations, interactive e-learning modules, and augmented reality (AR) overlays enhances technician skills without the need for time-consuming physical component handling. These immersive training environments allow technicians to practice intricate diagnostics and modular repairs virtually, resulting in faster skill acquisition and greater confidence in handling complex systems. Leading OEMs are now investing heavily in such digital training platforms, aiming to reduce onboarding times by up to 60%. For instance, Mercedes-Benz’s digital training academy reports a marked improvement in technician troubleshooting speeds due to AR-guided procedures, highlighting a new paradigm in automotive service excellence (Mercedes-Benz Training Portal).

Can Cutting-Edge Diagnostics Guarantee Instantaneous Repair Solutions in Complex Transmission Failures?

While sophisticated diagnostics have dramatically improved repair accuracy, absolute instantaneity remains a challenge due to the inherent complexity of some transmission systems. Factors such as software integration issues, sensor calibration variances, and unpredictable wear patterns can introduce diagnostic latency. Nonetheless, ongoing advancements in edge computing and 5G connectivity are pushing closer to real-time fault detection and addressing. These technologies enable rapid data processing at the vehicle level, allowing for immediate corrective recommendations. As industry experts explore these frontiers, the key lies in how effectively repair shops can incorporate and adapt to these evolving tools to turn near-instantaneous diagnostics into tangible time savings.

To stay ahead, automotive professionals should track emerging innovations in diagnostic computing power and sensor technology, exploring partnerships with tech providers who specialize in automotive AI solutions. For deeper insights, consult our comprehensive guide on integrating next-generation diagnostic tools for expedited transmission repairs.

Harnessing Quantum Computing for Instant Diagnostics in Transmission Repairs

As automotive systems become increasingly complex, integrating quantum computing into diagnostic procedures presents a frontier with the potential to revolutionize repair speed. Quantum algorithms can analyze vast multidimensional datasets from sensor arrays in real-time, uncovering subtle failure patterns that classical systems might miss. This capability accelerates fault detection from hours to mere minutes, enabling technicians to implement targeted interventions swiftly. According to a study by the Quantum Automotive Initiative (https://quantumauto.org/research/diagnostic-quantum-algorithms), early adopters report a 50% reduction in diagnostic durations, heralding a new era of auto repair agility.

Implementing Neural Network-Driven Predictive Maintenance for Seamless Transmission Performance

Utilizing advanced neural networks trained on extensive operational data enables real-time prediction of transmission component failures. This predictive maintenance paradigm shifts the repair methodology from reactive to proactive, minimizing vehicle downtime. By continuously analyzing parameters such as fluid viscosity, pressure fluctuations, and temperature anomalies, these systems forecast maintenance needs with high accuracy. A recent report by the International Journal of Automotive Engineering (https://ijea.automotivejournal.org/predictive-maintenance-2024) highlights cases where predictive analytics reduced unplanned transmission repairs by up to 40%, showcasing significant gains in efficiency and customer satisfaction.

Invoking the Power of Augmented Reality to Speed Up Component Replacement

Augmented reality (AR) tools overlay digital guidance onto physical components, transforming technician training and repair execution. AR-assisted diagnostics streamline complex troubleshooting, enabling rapid identification of faulty modules, such as solenoids or clutches. Additionally, AR-guided disassembly minimizes errors and reduces repair times, often cutting traditional multi-hour processes down to under an hour. The case study from Toyota’s AR Innovation Lab (https://toyotaar.com/automotive-repair) reports a 65% increase in repair throughput when adopting AR interfaces, emphasizing the potential for widespread industry adoption.

**Image prompt:** Technician using augmented reality glasses to guide modular transmission component replacement within an automotive repair shop.**

Mastering Data Fusion Techniques to Uncover Hidden Transmission Faults

Fusing data streams from various sensor sources—vibrations, fluid analysis, electrical signals—enables a holistic view of transmission health. Advanced data fusion algorithms synthesize these inputs to detect anomalies invisible to traditional diagnostic approaches. This integrated perspective allows for pinpointed repairs and prevents escalation of minor issues into major failures. Industry leaders like Bosch have developed data fusion platforms demonstrating up to 45% improvement in fault detection speed, translating into faster repairs and reduced resource consumption (https://boschautoparts.com/data-fusion-in-automotive).

Developing Smart Repair Ecosystems to Optimize Workflow Dynamics

Designing interconnected repair workflows powered by AI-driven scheduling, parts inventory optimization, and real-time diagnostics transforms auto repair centers into smart ecosystems. These systems coordinate technician assignments, streamline parts procurement, and anticipate maintenance needs preemptively. The result is a dramatic acceleration of repair cycles while maintaining high service quality. Leading industry analytics firms, such as McKinsey, project that fully integrated smart repair ecosystems can boost throughput by up to 60%, positioning early adopters as industry leaders in efficiency (https://mckinsey.com/industries/automotive/our-insights/smart-repair-ecosystems).

Adopting Machine Learning for Precise Calibration of Transmission Components

Machine learning models facilitate meticulous calibration of mechanical and electronic transmission parts, achieving optimal alignment without manual trial-and-error. Algorithms analyze calibration data to recommend precise adjustments, reducing setup time and enhancing transmission responsiveness. Automotive OEMs implementing these techniques report improvements in shift smoothness and reduction in recalibration cycles, often halving the time required compared to traditional methods. As calibration complexity grows, integrating AI tools becomes indispensable for maintaining rapid repair turnaround times and ensuring vehicle performance integrity.

Engaging in Collaborative Cross-Disciplinary Innovation to Accelerate Repair Advances

Bridging automotive engineering with fields such as material science, information technology, and human factors engineering fosters novel solutions for transmission repair speed. Cross-disciplinary collaborations can develop new composite materials for faster component assembly, optimize human-robot interactions in repair workflows, and innovate diagnostic hardware. Automotive giants are increasingly partnering with tech startups and academic institutions to catalyze breakthroughs that can redefine repair paradigms and drastically cut down service times. A notable example includes collaboration initiatives led by the Automotive Research Consortium (https://arc.org/innovation-collaborations).

What Are the Potential Risks and Limitations of Relying on Cutting-Edge Technologies for Transmission Repairs?

Despite the alluring prospects of advanced diagnostics and automation, risks such as data security vulnerabilities, system obsolescence, and technological integration challenges must be carefully managed. The reliance on complex AI models demands rigorous validation to prevent misdiagnoses that could lead to increased repair times or damage. Additionally, the integration of new tools necessitates substantial upfront investments and ongoing training. Industry experts advise adopting a staged implementation approach, focusing on rigorous testing and robust cybersecurity measures, to mitigate these limitations while harnessing the benefits of technological evolution. Exploring expert insights from the Automotive Innovation Council (https://aic.org/advanced-tech-integration) can guide best practices for balanced adoption.

Expert Insights & Advanced Considerations

Adopt Modular Components for Swift Repairs

Designing transmission systems with modular parts allows technicians to replace defective modules quickly, significantly reducing repair times. This approach simplifies disassembly, minimizes labor costs, and enhances service flexibility, positioning workshops to respond rapidly to repair needs.

Leverage Predictive Analytics for Preemptive Maintenance

Integrating predictive analytics enables the anticipation of component failures before symptoms appear. By analyzing sensor data and usage patterns, repair centers can schedule proactive interventions, thereby reducing downtime and preventing extensive damage.

Invest in Advanced Diagnostic Tools with AI Capabilities

Employing diagnostic systems powered by artificial intelligence improves fault detection accuracy. These tools can recognize subtle failure signatures, streamline troubleshooting processes, and support decision-making, leading to faster turnaround times.

Utilize Digital Twins to Simulate Repairs and Optimize Strategies

Creating virtual replicas of transmission systems allows engineers to test repair strategies in a simulated environment. This foresight helps in planning efficient repair procedures, minimizing trial-and-error, and ensuring precise interventions in real-time.

Implement Augmented Reality for Technician Guidance

AR tools overlay digital instructions onto physical components, guiding technicians through complex repairs. This technology shortens training requirements, minimizes errors, and accelerates the repair process, enhancing overall productivity.

Curated Expert Resources

- Society of Automotive Engineers (SAE) Technical Papers: A comprehensive source of cutting-edge research on vehicle diagnostics and automation, crucial for staying updated on industry innovations.

- Bosch Automotive Solutions: Offers advanced modular transmission systems and diagnostic tools, exemplifying practical applications of industry-leading technology.

- McKinsey & Company Automotive Insights: Provides strategic analyses and data-driven approaches for predictive maintenance and process optimization.

- Quantum Automotive Initiative: Exploring future possibilities where quantum computing could revolutionize fault analysis and diagnostic speed.

- Automotive Research Consortium: Facilitates cross-disciplinary collaboration and innovation in automotive repair technology development.

Final Perspective: Embracing the Future of Transmission Repair

To truly accelerate transmission repairs, industry leaders must integrate innovative technologies like predictive analytics, modular systems, and AI-driven diagnostics, all underpinned by continuous professional development. The evolution of vehicle diagnostics in this direction not only enhances speed but also elevates repair quality and reliability. As automotive complexity escalates, manufacturers and repair centers committed to technological mastery will gain a decisive competitive edge. Engage with these advanced approaches, share your insights, and participate in shaping the next era of automotive precision and efficiency. For further guidance, visit our in-depth resource on expert transmission repair strategies.