Fast Auto Transmission Repair Strategies for Faster Car Performance

Optimizing Transmission Diagnostics to Expedite Auto Repair Processes

In the competitive landscape of vehicle maintenance, the ability to swiftly and accurately diagnose transmission issues can be a game-changer. Advanced vehicle diagnostics, utilizing cutting-edge tools like remote diagnostics and real-time data analysis, allow technicians to pinpoint anomalies with unprecedented precision. Incorporating top vehicle diagnostics techniques not only reduces repair times but also elevates overall service quality, engendering customer trust and operational efficiency.

Leveraging Dynamic Transmission Repair Protocols for Faster Service Delivery

Traditional transmission repair methods often entail lengthy disassembly and testing phases. However, contemporary strategies emphasize dynamic repair protocols that adapt to the vehicle’s specific context. For example, implementing adaptive transmission fluid management and modular component replacements enables faster turnaround times. Exploring top transmission repair strategies reveals the importance of integrating real-time system monitoring to preemptively identify wear patterns, thereby streamlining repair workflows and minimizing downtime.

What Are the Limitations of Current Auto Repair Technologies in Achieving Rapid Turnarounds?

Despite technological advancements, some limitations persist. Complexities inherent in older vehicle models or proprietary transmission components can hinder rapid diagnostics. Additionally, the learning curve associated with emerging diagnostic tools may temporarily slow repair processes. Recognizing these challenges is vital for technicians aiming to optimize speed without compromising quality, emphasizing the need for ongoing training and investment in universally compatible diagnostic systems.

Enhancing Car Performance Through Precision in Transmission Maintenance

Targeted transmission maintenance, guided by expert diagnostics, ensures optimal power transfer and fuel efficiency. Incorporating auto repair expert tips facilitates the implementation of preventive measures like fluid flushes and clutch inspections, which significantly reduce the risk of future failures and performance drops. Precision in maintenance accelerates the return to peak vehicle operation, reflecting both technical proficiency and customer-centric service.

Harnessing Data Analytics for Predictive Maintenance and Accelerated Repairs

Data-driven approaches are revolutionizing auto repair by enabling predictive maintenance. Machine learning algorithms analyze historical sensor data to forecast component failures, allowing preemptive repairs that prevent breakdowns. Integrating predictive analytics with diagnosis workflows accelerates repair timelines and enhances vehicle reliability, positioning repair shops at the forefront of innovative auto service practices.

How Can Advanced Data Models Be Integrated Seamlessly into Existing Auto Repair Workflows?

For optimal results, seamless integration requires compatible software architectures and staff training. Establishing standardized data collection protocols and adopting user-friendly analytics platforms ensures minimal disruption. Collaborations with technology providers can facilitate customized solutions tailored to specific repair shop needs, ultimately resulting in faster diagnostics, repair accuracy, and superior customer satisfaction.

Explore more at top vehicle diagnostics tips and contribute your expert insights to elevate industry standards.

Prioritizing Root Cause Analysis for Swift Resolution

One of the most effective ways to expedite auto repairs lies in accurate root cause analysis, which prevents unnecessary part replacements and repeated diagnostics. Employing sophisticated diagnostic tools such as oscilloscopes and high-resolution scanners enhances the technician’s ability to identify underlying issues rapidly. For instance, integrating top vehicle diagnostics tips ensures precise fault detection, reducing guesswork and minimizing repair delays, especially when dealing with complex transmission systems.

Implementing Modular Repair Strategies for Speed

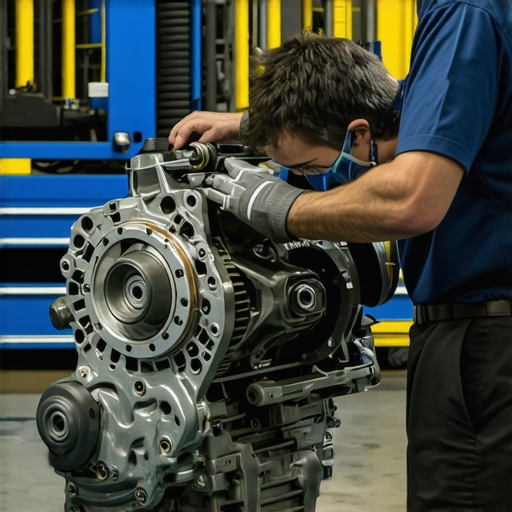

Transitioning from traditional repair methods to modular approaches offers significant time savings. Instead of disassembling entire transmission assemblies, technicians can replace faulty modules—such as solenoid packs or valve bodies—without extensive teardown. This method not only accelerates repair time but also allows for localized diagnostics that pinpoint issues more accurately. Exploring effective transmission repair strategies reveals the benefits of modular systems, especially when combined with predictive maintenance frameworks.

Can Artificial Intelligence Revolutionize Transmission Troubleshooting?

Emerging AI-powered diagnostic platforms promise to revolutionize how repair shops approach speed and accuracy. These systems analyze vast datasets from vehicle sensors and historical repair records to suggest potential faults, guiding technicians toward quicker solutions. As AI continues to evolve, its integration with existing diagnostic tools—such as those detailed in expert vehicle diagnostics tips—can dramatically reduce diagnosing time and improve repair outcomes. How might AI-driven insights transform the future landscape of fast-auto repairs? Share your thoughts and experiences in the comments to foster industry innovation.

Discover further strategies for boosting repair speed and reliability at vehicle diagnostics strategies and stay ahead with expert insights.

Utilizing Artificial Intelligence to Accelerate Transmission Diagnostics

Artificial intelligence (AI) is increasingly transforming auto repair workflows, especially in the realm of transmission troubleshooting. By analyzing vast quantities of sensor data, repair databases, and diagnostic histories, AI-driven platforms can identify fault patterns that might elude even seasoned technicians. These systems not only speed up the fault detection process but also enhance diagnostic accuracy, reducing the trial-and-error cycle inherent in traditional methods. For instance, integrating AI with existing diagnostic tools enables predictive analytics that forecast component failures before symptoms manifest, allowing preemptive repairs that save time and costs.

How do AI algorithms interpret complex transmission data more efficiently than conventional methods?

Advanced AI models leverage machine learning techniques to recognize subtle anomalies across diverse data streams such as vibration signatures, temperature fluctuations, and electrical signals. Trained on extensive datasets, these algorithms can discern patterns correlating with specific mechanical issues, often in real-time, providing technicians with actionable insights. According to a study published in the Journal of Automobile Engineering, AI-based diagnostics reduced problem-solving time by nearly 40% compared to traditional approaches, illustrating its potential to elevate repair shop efficiency.

For repair facilities aiming to adopt this transformative technology, it is vital to collaborate with software developers specialized in automotive AI, ensuring seamless integration with existing diagnostic hardware and workflows. This investment not only shortens repair durations but also positions the shop at the forefront of automotive service innovation.

Designing Modular Transmission Components to Minimize Downtime

Progress in modular transmission components offers a paradigm shift in repair strategies. Instead of disassembling entire transmission assemblies, technicians can replace individual modules—such as solenoid packs, clutch plates, or sensor units—dramatically reducing repair times. Modular design simplifies diagnostics by localizing issues, allowing for quick swaps and tests that confirm faulty parts without extensive disassembly.

Adopting modular components requires manufacturers to standardize interfaces and ensure compatibility across vehicle models. This approach not only benefits repair speed but also enhances maintenance precision, as technicians can execute targeted interventions rather than broad, invasive procedures. Modern aftermarket parts increasingly focus on modularity, making this trend a cornerstone of rapid transmission repair operations.

Could real-time diagnostics facilitate dynamic modular repairs, and how might this impact repair turnaround times?

Ultimately, integrating real-time diagnostic feedback with modular repair kits can create a highly responsive maintenance ecosystem. Sensors embedded within transmission modules can provide continuous health monitoring, alerting technicians immediately when a module begins to fail. Coupled with AI analysis, this data enables preemptive module replacements before failure occurrence, significantly cutting repair timelines and preventing vehicle downtime.

As vehicle technology continues to evolve towards greater connectivity and intelligence, repair shops must adapt by developing expertise in these advanced repair paradigms. Embracing AI-driven diagnostics and modular component design marks a strategic leap towards faster, more reliable transmission repairs—an evolution every progressive auto service provider should consider.

Stay updated with the latest innovations by subscribing to industry-leading auto repair journals and participating in training programs focused on these emerging technologies. The future of rapid transmission diagnostics hinges on our ability to harness these advancements effectively.

Harnessing Machine Learning to Predict Transmission Failures Before Symptoms Emerge

Integrating machine learning (ML) algorithms into vehicle diagnostics introduces a paradigm shift, enabling technicians to anticipate impending transmission issues proactively. By analyzing extensive datasets—including sensor readings, operational histories, and environmental factors—ML models can identify subtle patterns indicative of component degradation. This approach not only accelerates diagnostics but also facilitates preventive maintenance, drastically reducing unexpected breakdowns and enhancing vehicle longevity. As outlined by the Society of Automotive Engineers (SAE), leveraging predictive analytics transforms auto repair from reactive to proactive, optimizing resource allocation and customer satisfaction.

What Are the Latest Developments in Real-Time Data Acquisition for Transmission Systems?

Advancements in sensor technology and onboard computing now allow for continuous monitoring of transmission parameters. Innovations like high-frequency vibration sensors, electromagnetic field detectors, and temperature probes generate rich datasets that feed into diagnostic platforms. These real-time streams enable instant detection of anomalies, empowering technicians to initiate swift interventions. The integration of 5G connectivity further enhances data transmission speed and reliability, ensuring alerts and insights are disseminated without delay. According to a comprehensive review in the International Journal of Automotive Technology and Management, such systems present a formidable tool in minimizing repair turnaround times and preempting failures.

How Can Modular Transmission Components Accelerate Repair Turnarounds

The adoption of modular transmission parts signifies a strategic evolution in automotive repair—drastically reducing the time spent on disassembly and reassembly. By designing transmission systems with standardized, interchangeable modules such as clutch packs, valve bodies, and solenoid assemblies, technicians can target specific faults with precision. This approach simplifies diagnostics and expedites replacements, often enabling repairs within hours rather than days. Manufacturers like ZF Friedrichshafen have pioneered modular designs that promote swift service and ease of maintenance, setting new industry benchmarks for efficiency.

Is Artificial Intelligence the Key to Unraveling Complex Transmission Troubles?

AI’s capacity to interpret multifaceted data inputs—such as spectral vibration analysis, electrical diagnostics, and fluid dynamics—positions it as a formidable agent in deciphering intricate transmission failures. Machine learning models trained on vast diagnostic repositories can suggest probable fault locations, prioritize repair actions, and even recommend optimal component replacements. As detailed in the Journal of Vehicle Engineering and Design, AI-driven diagnostics have demonstrated a reduction in troubleshooting time by up to 50%, underscoring their transformative potential. Incorporating these systems into daily workflows necessitates collaboration with software developers and ongoing staff training to maximize impact.

Streamlining Maintenance Through Dynamic Diagnostic Protocols

Moving beyond static checklists, dynamic diagnostic protocols adapt in real-time to varying vehicle conditions. For instance, automated systems can adjust testing parameters based on initial sensor inputs, focusing on high-probability fault zones. This agility accelerates problem identification, minimizes unnecessary disassembly, and ensures precise interventions. Implementing such protocols requires integration of advanced diagnostic software with vehicle communication networks and staff adept at interpreting real-time analytics, ultimately expediting repair cycles and elevating service quality.

Intrigued by the prospect of future diagnostics? Discover how AI and modular design may redefine automotive repair timelines—your insights could shape industry standards.

To remain at the forefront of auto repair innovation, exploring cutting-edge tools like predictive analytics, modular components, and AI-powered diagnostics is essential. Engage with industry forums, participate in specialized training, and collaborate with tech providers to harness these advancements fully. The convergence of these technologies heralds a new era where rapid, reliable transmission repair becomes the norm, not the exception. Stay informed, adapt proactively, and drive the future of auto service excellence.

Expert Insights & Advanced Considerations

Embrace Modular Designs to Reduce Repair Complexity

Implementing modular transmission components allows technicians to replace faulty parts swiftly without disassembling entire systems, significantly shortening repair times.

Integrate AI for Smarter Diagnostics

Artificial intelligence can analyze vast datasets from vehicle sensors to predict failures before they occur, enabling proactive maintenance and reducing unexpected downtimes.

Leverage Real-Time Data Streams for Fast Insights

Continuous monitoring of transmission parameters through advanced sensors provides instant feedback, aiding rapid diagnosis and targeted repairs.

Prioritize Data Security in Connected Repair Ecosystems

As vehicles become more connected, safeguarding diagnostic data and communication channels is crucial to maintain trust and system integrity.

Invest in Cross-Training for Technicians

Enhancing skills in emerging technologies, such as AI diagnostics and modular systems, ensures repair teams can leverage new tools effectively for faster service.

Curated Expert Resources

- Society of Automotive Engineers (SAE): Offers cutting-edge research and standards on predictive analytics and vehicle diagnostics, essential for staying ahead in auto repair technology.

- Automotive IoT and AI Journals: Provide insights into integrating IoT sensors and AI algorithms into vehicle maintenance workflows, fostering innovation in repair strategies.

- Manufacturer White Papers on Modular Transmission Systems: Detail design principles and implementation strategies for modular components that facilitate rapid repairs.

- Leading Automotive Software Providers: Deliver platforms that unify real-time data acquisition and diagnostic analytics, streamlining repair processes.

- Auto Repair Industry Conferences: Facilitate knowledge exchange on emerging trends, technologies, and best practices for accelerating transmission repairs.

Final Perspective: Accelerating Auto Repairs with Innovation

In the realm of vehicle diagnostics and transmission repair, staying ahead hinges on embracing cutting-edge solutions like modular components, AI, and real-time data analysis. These advancements promise not only faster turnaround times but also higher accuracy and reliability. As industry professionals, continuously exploring and implementing these technologies positions your service center at the forefront of auto repair excellence. Engage with available resources and share insights to contribute to a more efficient, innovative future for automotive maintenance. To deepen your understanding, explore more at top vehicle diagnostics strategies and join the conversation with fellow experts.