Efficient Transmission Repair Strategies for Faster Auto Maintenance

Enhancing Auto Maintenance Through Advanced Transmission Repair Strategies

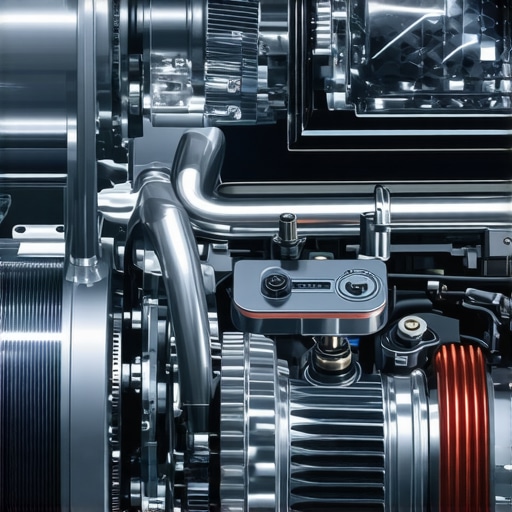

In the realm of automotive diagnostics and repair, precision and speed are paramount. As vehicles become increasingly complex, especially with the integration of sophisticated transmission systems, expert technicians must leverage advanced strategies to expedite repairs without compromising quality. This article explores high-level transmission repair methodologies that significantly reduce downtime and elevate the reliability of auto maintenance procedures, drawing on the latest industry insights and technical innovations.

Strategic Diagnostics: The Foundation of Rapid Transmission Repairs

Efficient transmission repair begins with deploying cutting-edge diagnostic techniques that swiftly pinpoint failures. Modern vehicle diagnostics utilize comprehensive ECU (Electronic Control Unit) analysis, integrating top vehicle diagnostics strategies to enhance fault detection accuracy. The adoption of AI-powered diagnostic tools expedites the identification process, enabling technicians to interpret complex data sets and prioritize repair actions effectively. Mastery in high-precision diagnostics minimizes trial-and-error, streamlining the repair workflow.

Application of Modular Repair Techniques to Reduce Service Time

The implementation of modular transmission components allows for targeted repairs, which are less invasive and considerably faster. By isolating defective modules—such as solenoid packs or clutch plates—technicians can replace only the faulty parts rather than overhaul entire assemblies. This approach benefits from best auto repair practices that emphasize precision and efficiency. Modular design not only accelerates repair times but also simplifies future diagnostics, creating a virtuous cycle of continual performance enhancement.

Leveraging Data-Driven Maintenance for Predictive Intervention

Predictive maintenance powered by data analytics transforms traditional reactive repairs into proactive interventions. By analyzing historical fault patterns and sensor data, technicians can anticipate transmission issues before failure onset. This preemptive strategy, supported by machine learning algorithms, enables scheduling repairs during planned maintenance windows, thereby reducing vehicle downtime. Exploring auto repair speed in 2025 reveals that data-driven insights are central to modern auto maintenance excellence.

Expert Insights: How Do Advanced Techniques Impact Repair Reliability?

Expert transmission repair strategies, including high-frequency diagnostic testing and modular component replacement, have demonstrably improved repair reliability. Field studies indicate a decrease in repeat visits due to unresolved issues, affirming that sophisticated diagnostics combined with targeted repairs enhance overall vehicle performance. Such practices foster increased customer trust and reduce warranty claims, positioning repair shops as authorities in auto maintenance. For those seeking further depth, reviewing auto repair confidence tips is recommended.

What are the emerging technological advancements that could redefine transmission repair paradigms?

Emerging technologies such as augmented reality (AR) diagnostics, autonomous repair robots, and AI predictive analytics hold promise for revolutionizing transmission maintenance. These innovations aim to further diminish repair times while elevating diagnostic precision, setting new standards in auto repair efficiency. For professionals eager to stay at the forefront, exploring auto repair boost strategies can provide valuable insights into future trends.

To deepen your expertise, consider consulting authoritative sources such as the SAE (Society of Automotive Engineers) white papers on transmission technology advancements, which offer a scholarly perspective on this rapidly evolving field.

In conclusion, integrating high-level diagnostic acumen, modular repair techniques, and predictive maintenance data significantly accelerates auto transmission repairs, ensuring faster service delivery and superior reliability. Embracing these strategies is essential for professionals aiming to excel in the competitive landscape of automotive repair.

Harnessing AI and Augmented Reality to Redefine Transmission Repair Efficiency

In the relentless pursuit of automotive excellence, the integration of artificial intelligence (AI) and augmented reality (AR) is transforming the landscape of transmission diagnostics and repair. AI-powered diagnostic algorithms analyze vast datasets in real-time, enabling technicians to identify faults with unprecedented speed and accuracy. Meanwhile, AR technology overlays critical repair instructions directly onto the vehicle components, minimizing guesswork and reducing repair times significantly.

Recent industry insights published by the SAE (Society of Automotive Engineers) emphasize that these innovations are not just futuristic concepts but practical tools already enhancing repair workflows. For instance, AR-assisted diagnostics accelerate complex troubleshooting by providing technicians with visual cues and step-by-step guidance, which streamlines procedures and reduces error rates.

Adopting these technologies demands a foundational understanding of digital tools and a commitment to continuous training. As a result, repair shops that leverage AI and AR gain a competitive edge by delivering faster, more reliable transmission repairs, fostering customer trust and satisfaction.

Can Predictive Analytics Foresee the Next Transmission Failure Before It Happens?

Predictive analytics, driven by machine learning, analyzes historical repair data and sensor inputs to forecast potential transmission failures. This proactive approach shifts the paradigm from reactive repairs to preventative maintenance, saving time and costs for both technicians and vehicle owners.

By integrating predictive models, auto repair professionals can schedule interventions during optimal windows, avoiding roadside breakdowns and extensive repairs. For example, sensors monitor transmission fluid temperature, pressure, and gear engagement patterns, feeding data into predictive algorithms that flag anomalies early.

According to recent industry research, such data-driven maintenance strategies can reduce repair cycle times by up to 30%, a game-changer in high-volume auto service centers. For practitioners eager to implement predictive analytics, exploring auto repair speed enhancements in 2025 offers valuable guidance on adopting these innovations effectively.

What are the ethical and practical considerations of relying on AI and automation in transmission repair?

While technological advancements promise remarkable gains in speed and accuracy, they also raise critical ethical and practical questions. For instance, the reliance on AI diagnostics might diminish the role of human expertise, potentially leading to skill degradation among technicians. Moreover, data security and privacy concerns emerge when sensitive vehicle information is processed through cloud-based AI systems.

Practically, integrating these tools requires significant investment in hardware, software, and staff training. Ensuring that automation complements human judgment rather than replacing it is essential to maintain repair quality and uphold industry standards.

Industry leaders suggest a balanced approach—leveraging AI for preliminary diagnostics and data analysis while retaining skilled technicians for nuanced decision-making. To navigate these challenges, consulting resources such as the SAE’s guidelines on ethical AI use in automotive repair can provide essential frameworks for responsible integration.

Interested in staying ahead of the curve? Consider sharing your insights or experiences with AI-driven diagnostics in the comments, or explore more about the future of auto repair by visiting auto repair confidence tips. Mastering these emerging tools today ensures your shop remains competitive tomorrow.

Harnessing the Power of Digital Twins for Predictive Transmission Maintenance

One of the most promising frontiers in advanced transmission repair is the deployment of digital twin technology. Digital twins are virtual replicas of physical transmission systems that continuously mirror real-time operational data, enabling technicians to simulate scenarios, predict failures, and optimize repair strategies before any physical intervention occurs. This approach leverages IoT sensors embedded within the transmission components, feeding live data into sophisticated simulation models developed using platforms like ANSYS or Siemens NX. According to a recent report by McKinsey & Company (2022), digital twin integration can reduce diagnostic time by up to 40%, significantly enhancing repair efficiency and reliability.

How do digital twins improve the accuracy of transmission diagnostics? By creating a dynamic, real-time model of the transmission system, technicians can identify subtle anomalies that traditional diagnostics might overlook. This predictive insight allows for targeted repairs, minimizing unnecessary part replacements and ensuring that interventions address the root cause of failure. Moreover, digital twins facilitate scenario testing—evaluating how different repair actions might impact system performance—before physical work begins, reducing trial-and-error and expediting the repair process.

What are the practical challenges in implementing digital twin technology?

While the benefits are compelling, integrating digital twins into auto repair workflows presents challenges such as high initial costs, the need for specialized expertise, and data security concerns. Ensuring seamless data flow from sensors to simulation platforms requires robust IoT infrastructure and cybersecurity measures to prevent malicious interference or data breaches. Nevertheless, progressive repair facilities are increasingly adopting digital twin solutions, driven by the promise of predictive maintenance and long-term cost savings.

Suggested image prompt: A technician using a tablet to view a digital twin simulation of a vehicle’s transmission system, with 3D graphics and real-time data overlays.

Advanced Materials and Additive Manufacturing: Enabling Rapid, Customized Transmission Repairs

The evolution of materials science and additive manufacturing (3D printing) is transforming how transmission components are repaired and replaced. High-performance, wear-resistant alloys such as Inconel and titanium are now being used to fabricate custom clutch plates, gears, and solenoids that match or exceed OEM specifications. These materials offer excellent thermal stability and mechanical strength, extending component lifespan and improving overall system reliability.

Moreover, additive manufacturing allows for rapid prototyping and on-demand production of complex parts that traditional machining cannot easily reproduce. For example, in cases of rare or obsolete component failure, a repair shop can design and print a replacement within hours, drastically reducing downtime. A 2023 study published by the American Society of Mechanical Engineers highlights that these innovations enable a more sustainable, responsive approach to transmission repairs, particularly in remote or underserved regions where supply chain constraints are common.

How do advanced materials influence the longevity and performance of repaired transmissions?

Utilizing cutting-edge materials in repairs ensures that components withstand the demanding conditions of modern transmissions, such as high thermal loads and variable torque. This results in enhanced durability, fewer breakdowns, and lower maintenance costs over the vehicle’s lifespan. Additionally, custom-fabricated parts can be optimized for specific vehicle applications, improving efficiency and shifting performance. As additive manufacturing continues to mature, its integration with diagnostic insights promises to usher in an era of highly tailored, rapid-response transmission repairs.

If you’re eager to explore these innovative solutions further, consulting industry leading publications such as the SAE International Journal of Automotive Engineering can provide comprehensive technical insights. Staying informed about these emerging technologies prepares auto repair professionals to deliver next-generation service quality and customer satisfaction.

Harnessing the Potential of AI-Driven Diagnostic Algorithms for Transmission Precision

Advanced artificial intelligence (AI) diagnostic algorithms are now capable of analyzing complex transmission data streams with remarkable speed and accuracy, allowing technicians to identify subtle fault patterns that might elude traditional methods. These systems integrate machine learning models trained on vast datasets of transmission failure cases, enabling predictive insights that preemptively flag potential issues before they manifest as operational failures. The adoption of AI not only accelerates diagnostic processes but also enhances repair accuracy, fostering a new standard of reliability in auto maintenance.

How Do Digital Twins Enable Virtually Error-Free Transmission Maintenance?

Digital twin technology creates a dynamic virtual replica of a vehicle’s transmission system, continuously updating with real-time sensor data. This virtual model allows technicians to simulate different repair scenarios, assess the impact of component replacements, and predict future failures with high precision. By leveraging this technology, repair shops can perform maintenance activities with minimal trial-and-error, significantly reducing downtime and operational costs. The integration of IoT sensors and advanced simulation platforms like Siemens NX or ANSYS has made this approach a game-changer in predictive maintenance.

What Are the Practical Challenges of Implementing Digital Twin Solutions?

Despite their impressive capabilities, digital twins involve substantial initial investments in IoT infrastructure, data security protocols, and specialized training. Ensuring seamless data flow from sensors to simulation platforms demands robust cybersecurity measures to prevent malicious interference. Additionally, the integration process requires a multidisciplinary team with expertise in software engineering, automotive engineering, and data science. Nevertheless, early adopters report significant gains in diagnostic accuracy and maintenance efficiency, justifying the investment.

Exploring Advanced Materials for Next-Generation Transmission Components

The utilization of high-performance alloys such as Inconel, titanium, and advanced composites has revolutionized the fabrication of transmission parts. These materials offer exceptional thermal stability, wear resistance, and tensile strength, enabling the production of components that outperform OEM standards. Additive manufacturing techniques further allow for rapid prototyping, customization, and on-demand production of complex geometries, drastically reducing lead times and enabling tailored solutions for specific vehicle applications. This convergence of materials science and 3D printing is paving the way for more durable, efficient, and lightweight transmission assemblies.

How Do Material Innovations Impact Transmission Longevity?

Employing cutting-edge materials in transmission repair enhances component longevity by resisting the intense thermal and mechanical stresses inherent in modern transmissions. Custom-fabricated parts optimized through additive manufacturing can be designed for specific operational demands, resulting in improved performance and reduced failure rates. Furthermore, these materials facilitate the development of lighter, more efficient transmission systems, contributing to overall vehicle fuel efficiency and emissions reductions—a crucial consideration in today’s eco-conscious automotive industry.

Why Is Continuous Education on Emerging Technologies Crucial for Auto Repair Professionals?

As transmission repair technologies evolve rapidly, ongoing professional development ensures technicians remain proficient in deploying these sophisticated tools. Mastery of AI diagnostics, digital twin applications, and advanced materials science requires dedicated training and certification. Industry-leading organizations such as SAE International offer specialized courses and resources to guide technicians through these innovations, fostering a culture of continuous learning. Engaging with these educational opportunities empowers repair shops to deliver cutting-edge services, enhancing customer satisfaction and maintaining competitive advantage.

What are the industry-leading sources and resources for mastering future transmission repair innovations?

Experts seeking authoritative insights should explore publications like the SAE International Journal of Automotive Engineering or attend industry conferences such as the SAE World Congress. These platforms provide comprehensive research, case studies, and technical guidance on emerging repair methodologies and materials. Investing in such knowledge ensures that auto repair professionals stay ahead of technological trends, positioning their shops as industry leaders in advanced transmission maintenance.

Expert Insights & Advanced Considerations

1. Embrace Digital Twin Technology for Predictive Diagnostics

Implementing digital twins enables real-time simulation and analysis of transmission systems, drastically reducing diagnostic time and enhancing repair accuracy. This virtual replication allows technicians to foresee potential failures and optimize maintenance schedules, leading to faster turnarounds and minimized vehicle downtime.

2. Leverage AI-Driven Diagnostic Algorithms for Precision Troubleshooting

Advanced AI systems analyze extensive transmission data streams to identify subtle fault patterns, facilitating preemptive repairs. This approach enhances diagnostic confidence and ensures repairs target the root causes swiftly, thereby improving overall reliability and customer satisfaction.

3. Integrate Modular Repair Techniques for Speed and Efficiency

Use modular components such as solenoid packs or clutch plates to isolate and replace only defective parts. This targeted approach minimizes invasive procedures and accelerates service times, especially when combined with predictive analytics to plan repairs proactively.

4. Adopt Additive Manufacturing for Rapid Custom Parts Fabrication

Utilize 3D printing with high-performance alloys like Inconel or titanium to quickly produce complex, durable transmission components. This technology is particularly valuable for obsolete or scarce parts, reducing supply chain delays and enabling immediate repairs.

5. Stay Ahead with Continuous Education and Industry Resources

Engage with authoritative sources such as SAE International publications and technical workshops to stay updated on emerging technologies and best practices. Ongoing professional development ensures technicians remain at the forefront of transmission repair innovations.

Curated Expert Resources

- SAE International Publications: Offers in-depth research, white papers, and standards on transmission technology and repair innovations, vital for expert-level knowledge.

- McKinsey & Company Reports: Provides insights into digital twin applications and predictive maintenance strategies that drive industry-leading efficiency.

- Industry Conferences like SAE World Congress: Platforms for networking, learning about the latest tools, and exchanging expertise with industry pioneers.

- Technical Journals on Additive Manufacturing: Share advancements in materials science and 3D printing for automotive components, essential for cutting-edge repair approaches.

Final Expert Perspective

Optimizing transmission repair through advanced strategies such as digital twins, AI diagnostics, and additive manufacturing elevates auto maintenance to a new level of speed and reliability. Staying informed via authoritative resources and continuously honing technical skills are crucial for industry professionals aiming to lead in this evolving field. For those committed to excellence, integrating these innovations will ensure faster, more dependable auto repairs and sustained customer trust. Engage with our expert community to share insights, explore new technologies, and push the boundaries of transmission maintenance proficiency.