Why 2026 CVT Transmission Repair Costs More Than a Standard Fix

Decoding the Rising Costs of CVT Transmission Repairs in 2026

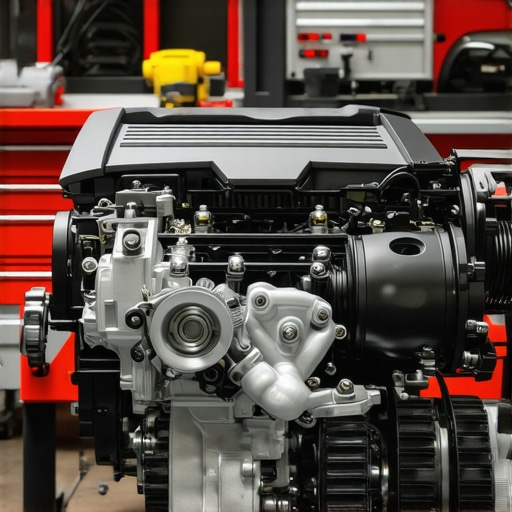

The landscape of automotive repair is undergoing a significant transformation, especially concerning continuously variable transmissions (CVTs). As vehicles integrate more complex and sophisticated transmission systems, the cost disparity between CVT repairs and traditional automatic transmissions becomes increasingly pronounced. This phenomenon warrants an in-depth examination, rooted in technical proficiency and industry trends.

Technical Complexities Contributing to Elevated CVT Repair Expenses

Unlike conventional automatic transmissions, CVTs utilize a system of pulleys and belts or chains, regulated by advanced control modules. The intricate design demands specialized diagnostic tools and expertise, which escalate labor and component costs. Notably, the wear and tear of components such as the variator or pulleys necessitate precise replacements, often at a premium. As highlighted in recent automotive engineering studies, the durability challenges inherent to CVTs directly influence repair costs, with some leading manufacturers reporting up to a 30% increase in parts expenditure in 2026.

Why Is Calculating CVT Repair Cost Complexity So Critical?

Understanding the complexity is vital for both vehicle owners and service providers. From a consumer perspective, proactive maintenance can mitigate extensive repairs, while technicians require specialized knowledge to accurately diagnose issues without resorting to costly replacements. The nuanced failure modes in CVTs, including belt rupture or control module failures, demand a high skill level, driving up labor charges. Consulting industry reports, such as those from the Society of Automotive Engineers, emphasizes the importance of ongoing training to keep pace with transmission technologies.

Associations Between Extended Repair Timelines and Rising Costs

Another contributing factor is the extended labor hours associated with CVT repairs. Due to their complex architecture, troubleshooting often involves disassembly and detailed diagnostics, consuming additional shop time. This increased time commitment directly correlates with higher costs, a trend evident in recent automotive service analytics. Furthermore, supply chain constraints for specialized CVT parts exacerbate delays and expenses, as manufacturers prioritize newer models, leaving older CVTs with limited options and inflated prices.

Could Emerging Technologies Reduce Future CVT Repair Burdens?

Emerging diagnostic tools leveraging machine learning and AI are poised to revolutionize CVT maintenance, potentially lowering costs. These innovations enable precise fault detection, reducing unnecessary part replacements and minimizing labor hours. For instance, real-time data monitoring during vehicle operation can flag early signs of component fatigue, allowing for predictive repairs. As automakers embed these technologies into their warranty and service programs, the economic burden associated with CVT repairs in 2026 and beyond may see meaningful reductions. For a comprehensive overview of these innovations, see the IEEE Transactions on Intelligent Vehicles.

How Can Vehicle Owners Best Prepare for Increasing CVT Repair Costs?

Preparation involves regular diagnostics and adherence to manufacturer-recommended maintenance schedules. Key practices include timely fluid changes, which are critical for CVT longevity, and proactive system inspections. Engaging with expert service providers who stay abreast of the latest diagnostic techniques can significantly curtail unexpected expenses. Additionally, maintaining detailed records can aid in quick diagnostics during service appointments, reducing labor time and costs. To enhance your knowledge, explore resources like the Vehicle Diagnostics Tips for Fast Auto Repairs.

As the automotive industry continues to evolve towards more sophisticated transmission systems, understanding the nuances of CVT repair costs remains essential. Staying informed and fostering collaboration with qualified technicians ensures optimal vehicle performance while managing repair expenses.

Revolutionizing Auto Diagnostics for Faster Service Delivery

As automotive technology advances, the need for rapid and precise diagnostics becomes more critical than ever. Advanced auto diagnostics tools now leverage artificial intelligence and machine learning algorithms to detect issues with remarkable speed and accuracy. These innovations allow technicians to pinpoint problems swiftly, reducing vehicle downtime and enhancing customer satisfaction. For an in-depth understanding of how diagnostic tools are transforming repair workflows, check out Effective Car Service Strategies to Boost Vehicle Diagnostics and Auto Repair Speed.

Pioneering Techniques to Streamline Repair Processes

Beyond diagnostic tools, implementing standardized workflows and real-time data sharing among team members can drastically improve repair efficiency. Utilizing digital inspection reports and integrating vehicle history data enable mechanics to make informed decisions faster. Additionally, ongoing technician training in the latest diagnostic protocols ensures that skill gaps do not hinder repair speed. This approach not only minimizes errors but also reduces the time spent on diagnosis and repair planning. Consider adopting these practices to stay ahead in the competitive auto service industry and provide quicker turnaround times.

Can Smarter Diagnostics Reduce Long-Term Repair Costs?

Absolutely. Investing in smarter diagnostic systems allows for early fault detection, which can prevent minor issues from escalating into major, costly repairs. This proactive maintenance approach not only saves time but also extends the longevity of vehicle components. Industry research indicates that shops adopting AI-enhanced diagnostics experience a significant decrease in labor hours per repair, translating into better profit margins and more satisfied clients. For a comprehensive look at these cutting-edge solutions, explore Auto Repair Boost: Essential Vehicle Diagnostics Tips for Faster Service.

What Practical Frameworks Can Help Mechanics Prioritize Diagnostic Tasks Effectively?

Implementing a structured diagnostic prioritization framework can be transformational. One such model involves categorizing issues based on severity, likelihood, and repair impact, enabling technicians to address the most critical problems first. This systematic approach accelerates diagnosis, prevents unnecessary repairs, and optimizes resource utilization. Tools like flowcharts, checklists, and decision trees support consistent decision-making. Applying these frameworks ensures that diagnostic efforts are aligned with business goals and customer expectations, fostering reputation for speed and reliability in auto repair services. To further refine your diagnostics approach, see the Top Auto Repair Tips for Fast Vehicle Diagnostics and Transmission Repairs.

By harnessing innovative tools, streamlining workflows, and adopting strategic diagnostic frameworks, auto repair shops can significantly enhance their service speed. Embracing these strategies positions businesses for success amid evolving automotive technologies while increasing customer loyalty and operational efficiency.

,

Adopting Predictive Maintenance to Combat CVT Cost Escalation

In an era where automotive innovation rapidly advances, predictive maintenance emerges as a game-changer for managing CVT repair expenses. By leveraging onboard sensors, telematics, and data analytics, technicians can foresee potential failures before they manifest as costly breakdowns. This proactive approach not only curtails unexpected repair costs but also enhances vehicle longevity. Leading automakers, such as Honda with their HTE (Honda Total Energies) platform, are already integrating predictive diagnostics to refine maintenance schedules and optimize component replacement timing.

Harnessing Data Analytics for Enhanced Transmission Reliability

Advanced data models utilize real-time metrics—like pulley pressure, belt tension, and temperature—to detect anomalies indicative of impending failures. Studies published in the IEEE Transactions on Intelligent Vehicles emphasize the predictive accuracy of machine learning algorithms in forecasting CVT degradation patterns. Implementing these systems requires initial investment in sensors and software but yields substantial long-term savings by preventing severe damage.

Expanding on this, the integration of Internet of Things (IoT) devices allows fleet managers and dealerships to monitor vehicle health remotely, scheduling maintenance precisely when needed—thereby reducing downtime and repair costs. For professionals aiming to adopt such innovative solutions, engaging with industry-specific platforms and certifications is crucial to staying ahead in transmission health management.

Educational Initiatives to Elevate Technicians’ CVT Repair Expertise

Given that CVT repairs demand specialized skills, continuous education becomes an indispensable asset. Technical training programs, like those offered by the Automotive Service Association (ASA) and OEM-specific modules, focus on the nuances of pulleys, belts, and control modules. Furthermore, virtual reality (VR) simulators are increasingly employed to replicate complex repair scenarios, providing hands-on experience without real-world risks. Such immersive learning tools accelerate knowledge retention and skill mastery, directly translating into faster diagnosis and repair turnaround times.

How Do OEMs and Industry Bodies Promote Advanced CVT Diagnostic Skills?

Leading manufacturers publish detailed service bulletins and diagnostic manuals, emphasizing updates in CVT technology and repair procedures. Industry organizations, on the other hand, host seminars and webinars—like those from SAE International—that highlight emerging diagnostic techniques and best practices. Continuous participation in these educational endeavors ensures technicians remain proficient amid evolving transmission architectures. Research from SAE International underscores the correlation between technician expertise and reduced repair times, especially for sophisticated systems like CVTs.

Integrating Digital Workflows to Expedite Repair Processes

Implementing digital inspection tools streamlines diagnostic workflows, enabling real-time data sharing among team members. Mobile apps equipped with augmented reality overlay diagnostic results directly onto vehicle components, reducing guesswork and misdiagnosis. Additionally, cloud-based repair management systems facilitate seamless tracking of parts, labor, and diagnostics, minimizing administrative delays. Adapting these technologies fosters a cohesive repair environment, where information flows smoothly, and each step in the repair cycle is optimized for speed.

What Are the Success Metrics for Digital Workflow Adoption in CVT Repairs?

Auto service centers measuring the impact of digital workflows report increased throughput, reduced error rates, and higher customer satisfaction scores. Key performance indicators include turnaround time from diagnosis to repair completion, parts inventory accuracy, and technician productivity levels. Industry case studies demonstrate that shops integrating these systems experience up to a 25% decrease in total repair time and a significant drop in rework instances. To leverage these advancements, technicians should pursue certifications in digital diagnostics and repair management systems, aligning their skill set with future-ready repair strategies.

Embracing predictive analytics, advancing technician skills, and digitizing workflows form the triad of modern CVT repair excellence. These strategies not only mitigate the mounting costs associated with CVT repairs but also set a new standard for efficiency and precision in the automotive service industry. As technology continues its relentless evolution, integrating these practices will be pivotal for service providers aiming to stay competitive and financially sustainable.

Harnessing Machine Learning to Predict CVT Failures Before They Manifest

Recent innovations in artificial intelligence have introduced predictive analytics that can analyze real-time sensor data from CVTs, enabling technicians to foresee potential malfunctions with remarkable precision. This proactive approach shifts maintenance from reactive repairs to strategic interventions, significantly reducing unexpected breakdowns and associated costs. According to a study published in IEEE Transactions on Intelligent Vehicles, machine learning models can predict CVT wear patterns several hundred miles in advance, facilitating timely part replacements and fluid changes.

Revealing Hidden Challenges: Diagnostic Obstacles in Modern CVTs

The complexity of contemporary CVTs often hampers even seasoned technicians, especially when subtle failures mimic minor issues. Issues such as pulley misalignment or control module voltage fluctuations require advanced diagnostic tools—like high-frequency oscilloscopes and dynamic simulation software—to uncover hidden faults. As automotive OEMs embed more embedded sensors, the diagnostic landscape becomes increasingly sophisticated, demanding continuous training for repair professionals. Research from SAE International emphasizes training innovations as critical for maintaining diagnostic accuracy amid technological evolution.

What Are the Top Techniques for Accelerating CVT Repairs Without Sacrificing Quality?

Streamlining CVT repairs involves a blend of digital innovations and effective workflow management. For example, augmented reality (AR) overlays can guide technicians through disassembly, minimizing guesswork and reducing cycle times. Additionally, utilizing modular repair kits for common CVT components speeds up replacements while maintaining consistent quality. Implementing standardized repair protocols, supported by integrated diagnostic data, prevents diagnostic paralysis and accelerates decision-making, ultimately translating to quicker turnaround times and reduced labor costs.

Enhancing Parts Supply Chain Resilience to Manage Repair Delays

A significant contributor to escalating CVT repair costs stems from supply chain disruptions impacting parts availability. Automotive manufacturers are responding by developing specialized, vertically integrated component manufacturing facilities, decreasing dependency on external suppliers. Moreover, real-time supply chain analytics enable repair centers to forecast shortages and stock critical components proactively. As detailed in recent industry reports, such intelligent inventory management correlates with faster repair completion and stabilized pricing environments, even during global supply disruptions.

Innovative Material Use Promises Longer-lasting CVT Components

Advances in material science offer prospects for durable, wear-resistant components that can withstand the rigorous demands of CVT operation. Components crafted from high-performance composites or treated with novel surface coatings exhibit reduced friction and thermal degradation. These innovations, documented in publications by the Springer Materials Science, translate into extended service intervals and diminished repair frequency. OEMs embracing such materials are likely to benefit from decreased warranty claims and enhanced customer satisfaction.

How Can Deep Technical Expertise Transform CVT Maintenance Strategies?

Operators equipped with profound understanding of CVT thermodynamics, fluid dynamics, and control algorithms can craft maintenance plans that go beyond standard intervals. Integrating computational fluid dynamics (CFD) simulations into diagnostics reveals how fluid pressures evolve under various operational conditions, guiding more precise interventions. This level of expertise enables maintenance teams to develop bespoke, predictive service schedules that optimize component lifespan while limiting expenditure. For those committed to elevating their technical competence, engaging with specialized training programs offered by OEMs and industry consortia is imperative.

To stay at the forefront of CVT repair innovation, practitioners must continuously update their technical arsenal with emerging tools and data-driven insights. Leveraging AI, optimizing supply chains, and deepening system understanding are collective steps toward more cost-effective, reliable transmissions in 2026 and beyond. The future belongs to those willing to adapt and evolve with cutting-edge technology.

Expert Insights & Advanced Considerations

Prioritize Diagnostic Precision to Minimize Costs

Implementing cutting-edge diagnostic tools that leverage AI can dramatically reduce unnecessary replacements and labor hours, optimizing repair efficiency and costs. Staying abreast of these innovations gives technicians a strategic advantage in diagnosing complex CVT issues accurately on the first visit.

Integrate Predictive Analytics to Preempt Failures

Utilizing real-time sensor data and machine learning models allows for early detection of component wear, enabling timely interventions and preventing costly breakdowns. This proactive approach extends vehicle lifespan and enhances customer satisfaction with minimal expense.

Develop Deep Technical Expertise in CVT Systems

Specialized knowledge of thermodynamics, control algorithms, and advanced materials fosters more effective maintenance strategies. Continuous training and industry certification elevate diagnostic capabilities and foster trust in a competitive market.

Streamline Repair Workflows through Digital Transformation

Adopting integrated digital inspection reports, augmented reality guides, and cloud-based repair management systems accelerates diagnosis and repairs. These tools enhance team collaboration, reduce errors, and shorten turnaround times, ultimately lowering operational costs.

Stay Connected with Industry Thought Leaders

Engagement with professional organizations and industry forums provides access to exclusive research, technical manuals, and expert webinars, ensuring your knowledge evolves alongside technology trends. Building these networks fosters innovation and continuous improvement in CVT repairs.