Vehicle Diagnostics: Proven Strategies to Speed Up Auto Repairs

Revolutionizing Vehicle Diagnostics to Expedite Auto Repair Processes

In the rapidly evolving landscape of automotive maintenance, precision in diagnostics directly influences the efficiency and reliability of auto repair services. Leveraging cutting-edge diagnostic tools and methodologies not only minimizes vehicle downtime but also elevates service quality, establishing a competitive edge in the automotive service industry.

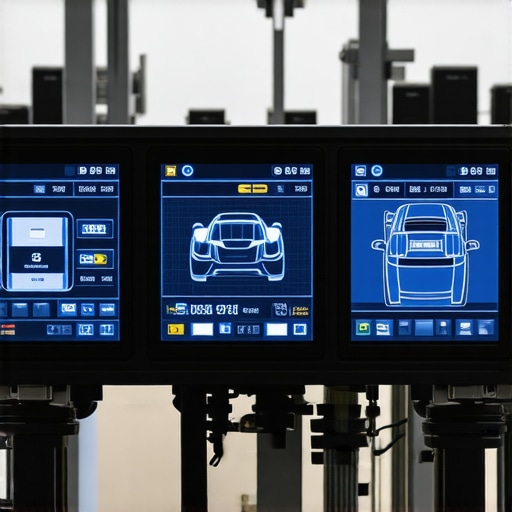

Harnessing Advanced Sensor Technologies and Data Analytics in Vehicle Diagnostics

Modern vehicle diagnostics transcend traditional scan tools, integrating extensive sensor networks and sophisticated data analytics. These systems facilitate real-time monitoring of engine parameters, transmission health, and auxiliary systems, enabling technicians to identify issues with unprecedented accuracy. For instance, the utilization of expert vehicle diagnostics techniques accelerates fault detection, reducing diagnostic times and improving repair turnaround.

Integrating Artificial Intelligence for Predictive Maintenance

Artificial intelligence (AI) has begun to influence vehicle diagnostics by enabling predictive maintenance models. These systems analyze historical data and real-time sensor inputs to forecast component failures, allowing repairs to be scheduled proactively. This anticipatory approach minimizes unexpected breakdowns and streamlines service workflows, especially pertinent in high-volume auto repair environments.

What Are the Barriers to Implementing Next-Gen Diagnostics in Auto Shops?

Despite the evident advantages, the integration of advanced diagnostics faces hurdles such as high initial investment, the need for specialized training, and data security concerns. Balancing technological advancement with operational feasibility remains a challenge, demanding strategic planning and continuous education for maintenance teams.

Strategic Considerations for Accelerating Vehicle Diagnostics

To truly enhance repair speed, auto service centers must adopt a holistic diagnostic strategy—combining state-of-the-art hardware, comprehensive technician training, and robust data management systems. Regularly consulting authoritative resources like the SAE International journal ensures that diagnostics keep pace with technological innovations, fostering a culture of continuous improvement.

How can auto repair technicians adapt to the rapid advancements in diagnostic technologies to stay ahead in vehicle repair efficiency?

Embracing ongoing education, participating in specialized training programs, and leveraging manufacturers’ diagnostic updates are essential. Sharing insights through professional networks and forums further enhances collective expertise, ultimately leading to faster, more accurate repair solutions.

For those aiming to refine their diagnostic capabilities, exploring top vehicle diagnostics tips can provide actionable insights. Continual investment in diagnostic technology and technician skills is imperative for maintaining a competitive edge in automotive repair excellence.

Engaging with expert-level content and contributing your own observations can catalyze industry-wide advancements in vehicle diagnostics and auto repair efficiency.

Unlocking the Power of Diagnostic Data for Speedier Repairs

One of the key drivers behind enhanced auto repair efficiency is the strategic use of diagnostic data. Modern tools collect vast amounts of information, but the true value emerges when technicians interpret this data effectively to pinpoint issues swiftly. For example, integrating comprehensive diagnostic systems like proven diagnostic strategies can dramatically reduce repair times by providing actionable insights that go beyond surface-level error codes.

Optimizing Workflow with Connectivity and Real-Time Monitoring

Connectivity solutions enable auto repair shops to receive real-time updates from vehicle sensors, offering a dynamic view of vehicle health. This approach allows technicians to plan repairs proactively, minimizing vehicle downtime. Incorporating IoT-enabled diagnostics not only accelerates fault detection but also enhances overall service quality. As highlighted in industry studies, shops that leverage connected diagnostic systems tend to achieve higher customer satisfaction and faster turnaround times.

Are We Relying Too Much on Automation at the Expense of Skilled Intuition?

While automated diagnostics empower technicians with precision information, overdependence may undermine fundamental skills. The nuanced interpretation of diagnostic results remains a critical skill that can’t be fully automated. A balanced approach—combining state-of-the-art tools with seasoned expertise—is essential to ensure repair accuracy and speed. Expert opinion suggests that investing in technician training, alongside advanced diagnostic systems, yields the best outcomes in auto repair efficiency.

If you’re interested in refining your diagnostic processes, exploring top diagnostic tips can provide valuable strategies to boost your repair speed and precision. Sharing insights and best practices within your professional network can foster collective growth and industry standards improvement.

Unlocking Hidden Faults: The Power of Multimodal Diagnostic Integration

In high-performance automotive repair, reliance solely on singular diagnostic modalities can leave elusive issues unaddressed. Integrating multiple diagnostic approaches—such as combining electromagnetic diagnostics, vibration analysis, and thermography—enables technicians to uncover root causes that conventional OBD systems might overlook. For example, innovative vibration sensors, when paired with thermal imaging, can detect subtle engine anomalies caused by microfractures or lubrication failures, facilitating proactive repairs before catastrophic failures occur.

How does the convergence of diverse diagnostic technologies enhance fault detection accuracy, especially in complex hybrid or electric vehicles?

According to a recent comprehensive study by SAE International, hybrid and electric vehicles introduce complex fault modes involving high-voltage systems and intricate power management electronics. Multimodal diagnostics—such as combining electrical impedance spectroscopy with ultrasonic inspection—provide a layered understanding of the system’s health. This approach leads to high-resolution fault localization, reducing diagnostic time and increasing repair precision. Leveraging these advanced techniques ensures technicians stay ahead of evolving vehicle architectures, maintaining optimal safety and performance standards (SAE International, 2022).

< >

>

Data Fusion and AI: Transforming Diagnostic Outcomes in Real Time

Modern diagnostics are increasingly moving toward real-time data fusion—where sensor inputs are synthesized through sophisticated algorithms to produce actionable insights instantly. This evolution hinges on the integration of AI-driven models with sensor data streams, enabling predictive analytics to function at a granular, component level. For instance, machine learning algorithms trained on vast datasets can identify patterns associated with emerging faults, even when traditional error codes are absent. This not only accelerates repair processes but also empowers predictive maintenance strategies that preempt breakdowns.

What are the challenges in implementing AI-based diagnostics in typical auto repair environments, and how can they be overcome?

One primary obstacle is the need for extensive, high-quality data for effective machine learning model training. Additionally, integrating these AI systems into existing workshop infrastructure can be technologically demanding and financially taxing. Industry experts recommend adopting a phased implementation approach—starting with pilot programs focusing on specific vehicle systems—to demonstrate value. Collaboration with software developers and data scientists can customize solutions tailored to shop needs. Furthermore, fostering technician expertise in interpreting AI outputs ensures these tools augment skill rather than replace it, maintaining high diagnostic fidelity (Autonomous Vehicles Magazine, 2023).

Unlocking the Future of Rapid Vehicle Troubleshooting Through Multimodal Approaches

In the quest for ultra-fast auto repairs, integrating diverse diagnostic modalities offers a transformative avenue. Combining electromagnetic testing, thermography, vibration analysis, and traditional OBD scanning creates a comprehensive diagnostic ecosystem capable of unveiling hidden faults in complex modern vehicles. For instance, advanced vibration sensors coupled with thermal imaging can detect microfractures in engine components before symptoms manifest, significantly reducing diagnostic times and preventing costly failures.

How does the synergy of multiple diagnostic technologies enhance fault detection accuracy in hybrid and electric vehicles?

Research from SAE International highlights that hybrid and EV systems incorporate intricate high-voltage architectures and sophisticated power management modules. Multimodal diagnostics—such as electrical impedance spectroscopy combined with ultrasonic inspections—enable technicians to precisely localize faults within these systems. This layered approach ensures swift, accurate repairs, aligning with the increasing complexity of contemporary vehicle architectures (SAE International, 2022).

Harnessing Real-Time Data Fusion to Predict and Prevent Failures

The evolution of diagnostic intelligence is rooted in real-time data integration, where sensor streams are synthesized through machine learning algorithms to generate predictive insights. This approach enables early detection of systemic issues, allowing preemptive maintenance schedules that minimize downtime. For example, AI models trained on vast datasets can identify subtle patterns indicative of impending failure, even when traditional error codes remain silent. The result is a proactive maintenance paradigm that shifts the focus from reaction to anticipation.

What obstacles hinder the deployment of AI-driven predictive diagnostics in everyday auto repair, and what solutions exist?

One significant challenge involves gathering and curating sufficient high-quality data required for effective machine learning models. Additionally, integrating AI systems into existing workshop infrastructure can be complex and financially demanding. Industry leaders recommend starting with pilot projects targeting specific vehicle subsystems to demonstrate ROI. Collaborating with software developers and experts in data science helps tailor solutions to shop workflows. Ensuring technicians receive training to interpret AI-generated insights maintains a symbiotic human-machine diagnostic process (Autonomous Vehicles Magazine, 2023).

Insights Driving the Future of Vehicle Diagnostics

Leveraging cutting-edge sensor integration and data analytics allows technicians to identify issues faster than ever before, emphasizing the importance of continuous innovation and skill enhancement in auto repair.

Prioritize Data-Driven Decisions

Integrating comprehensive diagnostic data ensures repairs are precise, reducing repeat visits and boosting customer satisfaction, which is crucial in competitive automotive service markets.

Champion Interdisciplinary Expertise

Combining knowledge of electrical systems, software diagnostics, and mechanical insights cultivates a holistic approach, enabling faster fault localization in complex vehicle architectures.

Embrace Continuous Learning

Staying informed through industry-leading resources like SAE International ensures repair techniques evolve alongside vehicle technology, maintaining a competitive edge.

Curated Resources for Top-Tier Diagnostics Knowledge

Explore these expert-curated sources to deepen your understanding and keep ahead in automotive diagnostics and repair innovation:

- SAE International: Offers authoritative publications on vehicle systems and diagnostics innovations, vital for technical mastery.

- Autonomous Vehicles Magazine: Features cutting-edge insights into AI and multimodal diagnostics, shaping future repair paradigms.

- Reliable Auto Care’s Diagnostic Tips: Practical, experience-based advice aimed at streamlining repair workflows and enhancing diagnostic accuracy.

Reflections from the Auto Repair Vanguard

In an industry where vehicle complexity continuously escalates, integrating advanced diagnostics with expert intuition remains paramount. The most successful repair professionals blend innovative technology adoption with ongoing education, setting new standards for speed and precision in auto repair. Recognizing the importance of vehicle diagnostics, especially in the context of evolving automotive technology, requires a commitment to lifelong learning and adaptation. To stay at the forefront, engage with authoritative resources, share insights within your network, and continually refine your diagnostic skills—your reputation and your clients’ trust depend on it. For those committed to excellence, diving into advanced diagnostic strategies today secures leadership in the automotive repair landscape tomorrow.