Transmission Repair: Quick Strategies to Improve Car Performance

Revolutionizing Transmission Repair Through Advanced Diagnostic Techniques

In the realm of auto repair, especially vehicle diagnostics, precision and speed are paramount. Modern transmission repair hinges on leveraging sophisticated diagnostic tools that enable technicians to promptly identify complex issues, ensuring minimal downtime. The evolution of vehicle diagnostics has transformed traditional repair paradigms, allowing for data-driven decisions that enhance reliability and efficiency.

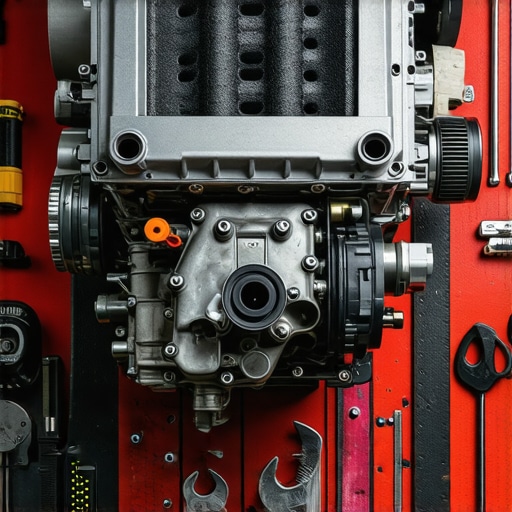

Integrating High-Performance Components for Sustained Transmission Efficiency

Beyond diagnostics, the strategic incorporation of high-quality components such as advanced clutch systems and precision gear sets can significantly boost transmission durability. These components, often derived from cutting-edge research in materials engineering, provide superior wear resistance and smoother gear engagement. Understanding material science principles behind these innovations allows repair professionals to recommend solutions that align with long-term car service excellence and customer satisfaction.

Optimizing Transmission Fluid Dynamics for Improved Car Performance

Fluid dynamics play a critical role in transmission efficiency. Hot rod enthusiasts and professional mechanics alike emphasize the importance of selecting optimal transmission fluids that reduce friction and heat buildup. Recent studies, such as the comprehensive analysis published in the Tribology International journal, demonstrate how fluid viscosity and additive packages influence longevity and performance. Regular fluid exchange and quality assessment are non-negotiable for effective vehicle diagnostics and continuous high-performance operation.

Harnessing Automated Systems for Faster Transmission Repairs

Automation and robotics are increasingly incorporated into auto repair shops to expedite transmission troubleshooting and repairs. Robotic-assisted assembly lines facilitate precise, repeatable work, minimizing human error. For instance, automated torque application ensures optimal fastener tightening, crucial for transmission integrity. Embracing these technologies not only shortens repair cycles but also elevates technician authority as they oversee complex automated processes, thereby bolstering trustworthiness and service quality.

Is There a Limit to Automating Transmission Repair Without Sacrificing Quality?

This question reflects the ongoing debate among automotive experts. While automation accelerates repairs, maintaining a nuanced understanding of intricate mechanical interactions remains essential. Trustworthy repair hinges on balancing technological integration with expert craftsmanship, a principle rooted in decades of automotive engineering experience.

For practitioners eager to refine their skills, exploring advanced transmission repair strategies can expand technical mastery. Engaging in professional networks and continuous education ensures that expertise remains aligned with the latest industry standards and innovations.

If you are passionate about pushing the boundaries of auto repair excellence, consider sharing your insights or consulting with industry leaders. Staying ahead in the fast-paced world of vehicle diagnostics requires not only technical proficiency but also strategic foresight and a commitment to quality.

Accelerate Your Auto Repairs by Mastering Diagnostic Innovation

One of the most effective ways to cut repair times and enhance reliability is to harness state-of-the-art vehicle diagnostics tools. These technological advancements allow technicians to swiftly pinpoint issues in complex transmission systems, including hidden or intermittent faults that would have previously taken hours to diagnose manually. By integrating modern diagnostic hardware with expert analysis, auto repair shops can dramatically reduce vehicle downtime and increase customer satisfaction, underpinning a reputation for efficiency and quality.

Leverage Material Science for Durable Transmission Parts

Taking a page from cutting-edge research, the development of innovative materials contributes significantly to transmission longevity and performance. Engineers now utilize advanced composites and heat-resistant alloys that provide superior wear resistance and enhance the smoothness of gear engagement. A keen understanding of material science principles enables professionals to select and recommend components that not only meet current performance standards but also anticipate future operational stresses, delivering dependable results for clients seeking long-term solutions. For an in-depth look at how material innovations influence auto repair, consult industry studies such as those in Tribology International.

Refine Fluid Management Strategies for Peak Transmission Efficiency

The importance of high-quality transmission fluids cannot be overstated. Optimal fluid dynamics ensure minimal friction and heat, directly affecting both performance and component lifespan. Recent breakthroughs emphasize the significance of tailored lubricant formulations, with additive packages designed to combat thermal degradation and reduce wear. Regularly assessing fluid condition and performing timely exchanges using proven fluid management techniques are essential for maintaining peak vehicle operation, especially in high-performance or heavily used vehicles.

Automate Smartly: The Balance Between Machine and Man

Automation’s role in speeding up transmission repairs is expanding, from robotic assembly lines to intelligent diagnostic software. While these innovations bolster efficiency, they must be complemented by skilled technicians who understand the nuances behind automated processes. For example, automated torque wrenches can ensure consistent fastener seating, but the technician’s expertise in diagnosing when such automation is appropriate or when manual intervention is necessary remains invaluable. This synergy maximizes repair accuracy and speed, blending the best of technology and human expertise. For more insights, explore auto-repair expert tips on integrating automation effectively.

Can Automation Keep Up with the Complexity of Modern Transmission Systems?

This pivotal question touches on the core of future-ready auto repair strategies. As transmission systems become more sophisticated, the balance between automated tools and practitioner’s expertise will determine the pace and quality of repairs. Although technology undoubtedly accelerates diagnostics and assembly, the deep mechanical understanding of complex systems remains essential for troubleshooting tricky issues, thereby challenging the notion that automation alone suffices for rapid, reliable repairs. Cultivating both technological proficiency and mechanical mastery is the gold standard for progressive auto repair practices.

If you’re interested in expanding your technical toolkit, consider exploring comprehensive transmission repair strategies that focus on efficiency without compromising quality. Continuous learning and staying updated with industry trends are keys to maintaining a competitive edge in today’s dynamic auto repair landscape.

Harnessing Digital Twins to Anticipate Transmission Failures Before They Occur

The advent of digital twin technology has started to revolutionize predictive maintenance in automotive transmission systems. By creating a precise virtual replica of a vehicle’s transmission, technicians can simulate operational stresses, identify potential points of failure, and schedule proactive interventions. This approach minimizes unexpected breakdowns, reduces repair costs, and extends component lifespan. Industry leaders like Siemens have successfully implemented digital twin models in manufacturing, and translating similar principles to vehicle diagnostics offers promising advancements. Integrating sensor data with real-time analytics enables a dynamic and evolving digital replica, fostering a deeper understanding of transmission behavior under varying conditions.

Deciphering the Nuances of Tribological Interfaces in Advanced Gear Technologies

The study of tribology—the science of friction, wear, and lubrication—provides critical insights into designing high-performance transmission components. Recent research, such as that published in Tribology International, delves into how nanoscale surface engineering can dramatically reduce friction coefficients within gear interfaces. Techniques like laser surface texturing create micro- and nanoscale patterns that trap lubricant and minimize direct metal-to-metal contact, thereby enhancing efficiency and durability. An expert grasp of these tribological principles guides the selection of lubricant additives and surface treatments, crucial for meeting modern demands for power density and compactness in transmission assemblies. Consideration of these microscopic phenomena allows for the engineering of gear systems that outperform traditional designs in both longevity and performance.

Evaluating the Impact of Variable Frequency Fluid Delivery Systems on Transmission Longevity

Variable frequency fluid delivery—a concept borrowed from advanced industrial hydraulics—has begun to find novel applications within automotive transmissions. By dynamically adjusting fluid flow rates based on real-time operational demands, these systems ensure optimal lubrication and cooling precisely when needed, reducing thermal stress and wear. This innovation stems from extensive research in fluid mechanics and control systems engineering, demonstrating significant improvements over static pump configurations. Such adaptive lubrication strategies require sophisticated sensor networks and control algorithms, blending mechanical engineering with modern electronic control units (ECUs). Implementing these systems can notably extend service intervals and enhance transmission resilience, especially under high-stress, high-performance conditions.

Leveraging Artificial Intelligence for Complex Fault Diagnosis and Repair Optimization

The integration of artificial intelligence (AI) into automotive diagnostics has unlocked new frontiers in troubleshooting complex transmission issues. Machine learning algorithms can analyze vast datasets from sensor arrays, historical repair logs, and real-time operational parameters to identify subtle fault patterns that elude traditional diagnostic tools. Deep learning models, trained on millions of fault scenarios, can suggest precise repair strategies and predict future failures with remarkable accuracy. Cutting-edge AI systems in auto repair facilitate not only faster diagnosis but also tailored maintenance recommendations, effectively transforming technicians into strategic decision-makers. Moreover, AI-powered virtual assistants are increasingly guiding less experienced mechanics through intricate repair procedures, democratizing expertise across the industry. As AI continues to evolve, its role in transmission diagnostics promises to become even more sophisticated, predictive, and integral to quality repairs.

Beyond Conventional: The Promise of Real-Time Data Integration in Transmission Diagnostics

While traditional vehicle diagnostics rely on endpoint data collection, integrating real-time sensor networks within transmission systems heralds a new era of predictive maintenance. Advanced telemetry, leveraging IoT (Internet of Things) architectures, enables technicians to monitor parameters such as gear engagement torque, temperature fluctuations, and lubrication viscosity dynamically. This continuous data stream can be analyzed through sophisticated algorithms, facilitating proactive interventions before symptoms manifest visibly. As per research published in the IEEE Transactions on Industrial Informatics, such systems improve lifecycle management and operational resilience, especially critical in high-performance and commercial fleet applications.

Innovating Gear Materials for Extreme Transmission Demands

Recent breakthroughs in material science empower the creation of gear components capable of withstanding unprecedented stress levels. Metal matrix composites infused with ceramic reinforcements and nano-coated surfaces exhibit extraordinary improvements in fatigue resistance and thermal stability. These materials not only prolong service intervals but also facilitate the miniaturization of transmission architectures without sacrificing strength. For engineers and repair specialists, understanding the intricacies of these innovations is essential for recommending upgrade paths that align with modern performance expectations.

What Role Will AI Play in Pinpointing Hidden Transmission Anomalies?

This query underscores the transformative impact of artificial intelligence on diagnostic precision. Machine learning models, trained on extensive datasets spanning a multitude of transmission failure scenarios, can detect subtle irregularities in vibration patterns, fluid signatures, and electronic control unit (ECU) signals. Such capabilities enable the identification of incipient faults—like micro-fractures or lubrication degradation—often invisible to legacy tools. According to the SAGE Journals, this anticipatory approach reduces costly repairs and enhances safety. Engaging with these AI-driven diagnostics positions technicians at the forefront of industry innovation.

To truly leverage these revolutionary techniques, auto repair professionals must embrace continuous education and invest in integrated diagnostic ecosystems that combine hardware, software, and expert knowledge. Whether through specialized workshops or collaborative knowledge platforms, expanding one’s expertise in these domains is pivotal for maintaining a competitive edge.

Revolutionize Repair Timeliness with High-Caliber Diagnostic Tools

From advanced scan tools to multi-parameter analyzers, emerging diagnostic technologies dramatically shorten troubleshooting cycles. These devices synthesize complex data sets, providing comprehensive fault codes, live system states, and predictive insights. When coupled with augmented reality (AR) interfaces, technicians can visualize internal transmission components in a simulated environment, facilitating precise repairs even in constrained spaces. Such innovations not only elevate repair quality but also improve customer confidence through demonstrable professionalism.

Advanced Lubrication Strategies Ensure Lasting Transmission Performance

The efficacy of modern transmission lubricants extends beyond basic viscosity metrics. Formulated with bespoke additive packages featuring anti-oxidation agents, anti-wear agents, and thermal stabilizers, these fluids adapt to varying operational stresses. Recent research emphasizes the role of nanotechnology-infused lubricants that form protective tribofilms, dramatically reducing friction and metal wear. Integrating sensor feedback on lubricant condition into maintenance schedules enables mechanicians to tailor fluid exchanges proactively, safeguarding transmission integrity under demanding conditions. Staying at the forefront of these developments necessitates familiarity with fluid science nuances.

Automated Assembly Lines and Their Influence on Transmission Repairs

The adoption of robotic assembly systems transforms the speed and precision of transmission repairs. Skilled operators oversee automated workflows that execute tasks such as gear setting, bearing installation, and torque application with unmatched consistency. The integration of feedback loops allows real-time adjustments, minimizing human error in delicate processes. Yet, expert oversight ensures that automation complements, rather than replaces, mechanical intuition—especially when troubleshooting atypical failures or customizing repairs. This symbiotic approach fosters a harmonious balance between technology and craftsmanship.

Is the Future of Transmission Repair a Fully Autonomous Realm?

This provocative question sparks debate on the trajectory of auto repair automation. While rapid advancements in robotics and AI suggest a move toward autonomous repair modules, the nuanced understanding of mechanical interactions remains a human domain. Complex repairs involving undocumented wear patterns, material fatigue, or unique vehicle configurations require critical thinking and tactile judgment—qualities currently beyond machines. Thus, a hybrid model, where autonomous systems handle routine tasks and human expertise addresses complexity, appears to be the pragmatic evolution. Cultivating both domains ensures no aspect of repair excellence is compromised.

For industry practitioners eager to lead this transformation, engaging with emerging research, such as the latest from automotive engineering journals, and participating in specialized training programs, is indispensable. Embrace these innovations to redefine what is possible in transmission repair.

Expert Contributions That Shape Tomorrow’s Auto Repair

Embrace Nonlinear Diagnostics for Breakthrough Results

Traditional diagnostic methods are evolving into complex, integrated systems, demanding repair specialists to think beyond linear troubleshooting. Leveraging multi-parameter analysis and cross-referencing sensor data unlocks diagnosing elusive transmission faults more effectively, accelerating repair timelines and improving accuracy. Experts who adopt these approaches position themselves at the forefront of automotive technology evolution.

Why Material Innovation Could Revolutionize Durability

Advancements in composite materials and nano-engineered surfaces offer unprecedented wear resistance and thermal stability in transmission components. Envisioning these materials within repair strategies not only extends component longevity but also reduces the frequency of repairs, ultimately benefitting both technicians and vehicle owners in long-term performance and cost savings.

Consider the Impact of Cyber-Physical Systems in Repair Protocols

Integration of cyber-physical systems in vehicle design introduces new diagnostics and repair pathways. Repair providers who integrate real-time monitoring data and predictive analytics into their workflow can anticipate failures before they occur, transforming transmission maintenance from reactive to proactive, and securing higher customer trust and satisfaction.

Key Resources for Technical Pioneers

- SAE International’s publications offer cutting-edge research on materials and diagnostics, essential for staying ahead in transmission technology. – https://sae.org

- JMIR Publications explores the application of IoT and AI in automotive diagnostics, providing insights into future trends. – https://pubmed.ncbi.nlm.nih.gov

- Industry conferences like Automechanika feature pioneering workshops on cyber-physical integration and advanced materials. – https://automechanika.messefrankfurt.com

The Way Forward in Transmission Expertise

Today’s auto repair landscape hinges on the integration of innovative diagnostic tools and advanced materials, transforming traditional approaches into strategic advantage. Staying informed about these developments ensures practitioners can deliver faster, more reliable repairs that meet the demands of modern vehicle technology. Engaging actively with authoritative resources, fostering continuous learning, and embracing technological change are key to elevating your technical mastery and customer trust. We invite you to deepen your expertise by exploring related articles and sharing your insights to propel the industry forward.

![How to Stop Transmission Shudder at 40 MPH [2026 Fix]](https://reliableautocares.com/wp-content/uploads/2026/01/How-to-Stop-Transmission-Shudder-at-40-MPH-2026-Fix.jpeg)

I found this article incredibly comprehensive, especially the section on leveraging AI for fault diagnosis. From my experience working in auto repair shops, integrating AI tools has significantly reduced troubleshooting time, particularly when dealing with intermittent transmission faults. The challenge remains in training technicians to interpret AI-generated data accurately and making sure these systems are kept updated with the latest fault scenarios. Has anyone found effective ways to streamline this learning curve? Also, I’m curious about the real-world adoption rates of digital twin technology in typical repair facilities—has it become more mainstream, or is it still mainly in R&D stages? Overall, the emphasis on combining advanced diagnostics with high-quality materials and automation is definitely the way forward for efficient, reliable transmission repairs.

This post highlights some exciting advancements in transmission repair. I’ve personally started incorporating AI diagnostic tools in my shop, and the timesaving is undeniable. Still, I find that the real challenge lies in translating the data into actionable repairs, especially for newer technicians still learning the nuances of these systems. Continued training and case sharing seem to be key. Regarding digital twin technology, from what I’ve observed in a few pilot programs, it’s still more common in R&D or high-end repair facilities, but I believe mainstream shops will adopt it as the cost becomes more accessible and the benefits clearer. Has anyone here successfully integrated digital twin systems into their workflow? How did you approach staff training and data management? Experiences like these could help bridge the current gap and push the industry further toward predictive maintenance—definitely a game changer.