Transmission Repair: Effective Strategies for Faster Car Performance

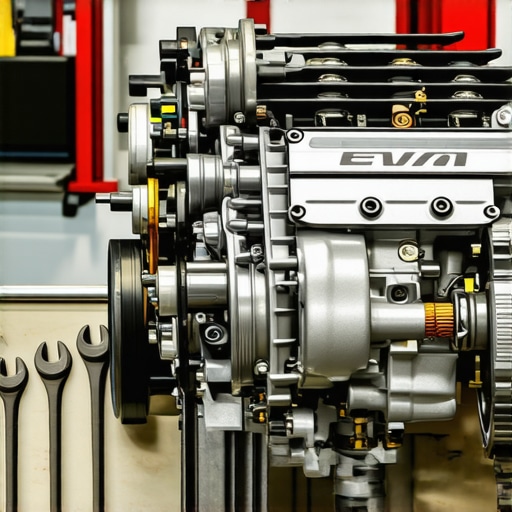

Enhancing Transmission Repair Efficiency: The Gateway to Optimal Vehicle Performance

In the competitive realm of auto diagnostics and auto repair, the ability to expedite transmission repair processes without compromising quality stands as a hallmark of automotive mastery. Leveraging cutting-edge diagnostic tools and understanding complex transmission behaviors enable technicians to diagnose issues swiftly and implement precise repairs, substantially reducing vehicle downtime and elevating customer satisfaction.

The Scientific Basis Behind Accelerated Transmission Diagnostics

Modern vehicle transmissions are intricate systems where mechanical, hydraulic, and electronic components interplay dynamically. Advanced diagnostic protocols employ machine learning algorithms and high-fidelity sensors to decode fault codes efficiently, providing a granular understanding of internal malfunctions. Such approaches transcend traditional trial-and-error methods, aligning with best practices detailed in authoritative studies like the AutoShop 3000 white paper on automatic transmission diagnostics.

Identifying Surprising Factors That Impede Transmission Service Speed

Could Outdated Fluid Really Be the Hidden Culprit?

While technicians often focus on mechanical wear and electronic faults, overlooked factors such as inexpensive transmission fluid degradation can significantly slow down repair procedures. Contemporary research underscores the importance of timely fluid analysis to prevent misdiagnoses and avoid unnecessary component replacements, streamlining overall auto repair workflow.

Strategic Integration of Transmission Repair and Vehicle Diagnostics

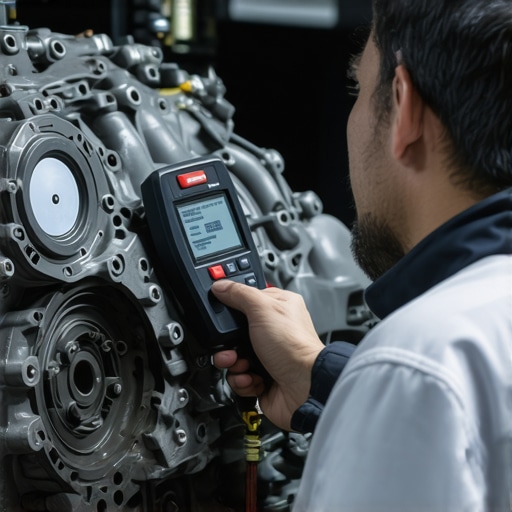

Integrating comprehensive diagnostic platforms with transmission repair workflows enhances procedural speed and accuracy. For instance, remote diagnostic systems can preemptively identify potential failures, enabling planning and precise resource allocation before physical repairs commence. This holistic approach is crucial for auto repair shops aiming to meet the surging demand for faster, dependable service here.

Accelerate Your Auto Service Skills: The Path to Expertise

Continual education, such as specialized transmission repair courses and staying updated with industry innovations, empowers auto repair professionals to execute repairs with surgical precision and speed. Fostering an environment of knowledge sharing and employing state-of-the-art diagnostic tools fundamentally transforms the auto repair experience for technicians and customers alike.

,

Revolutionize Your Approach with Proactive Vehicle Diagnostics

In the fast-paced world of automotive repair, staying ahead requires integrating anticipatory diagnostic methods into your workflow. Forward-thinking auto repair shops utilize predictive diagnostics that leverage real-time data and artificial intelligence to pre-emptively identify potential issues, drastically reducing repair times and enhancing customer satisfaction. Such strategies outperform traditional reactive techniques, enabling technicians to address problems before they escalate, as emphasized in industry-leading insights available here.

How Do Advanced Diagnostic Tools Transform Repair Speed?

Modern diagnostic devices, equipped with high-speed processors and comprehensive databases, provide instant fault code analysis and trend predictions. These tools can interpret complex transmission signals and mechanical behaviors with unprecedented accuracy, effectively decreasing diagnostic cycles. Incorporating such technology aligns with expert recommendations aimed at boosting repair efficiency. Moreover, integrating digital twin models allows technicians to simulate repairs virtually, clarifying potential failure points and enabling targeted interventions that save time and resources.

Challenging Assumptions: Is More Always Better in Diagnostics?

Contrary to common belief, deploying excessive diagnostic scans or overly complex systems can bog down repair processes, leading to analysis paralysis. Striking a balance between comprehensive data collection and practical application is essential. This nuanced approach involves selecting diagnostic protocols tailored to the specific vehicle and issue, avoiding unnecessary procedures that may delay repair timelines. It’s a delicate art mastered through ongoing education and experience, underscored by industry experts in effective repair strategies.

What innovative diagnostic techniques will set the next standard in auto repair speed?

Adopting machine learning algorithms capable of analyzing vast swathes of data instantly is poised to revolutionize auto diagnostics further. These advancements promise to refine fault detection accuracy and predict vehicle failures well before symptoms arise, leading to faster, more reliable repairs. Encouraging ongoing professional development ensures technicians can master these emerging tools and harness their full potential, ultimately delivering a superior auto repair experience.

Interested in elevating your repair shop’s diagnostic capabilities? Explore comprehensive training programs and latest diagnostic systems that integrate seamlessly with your workflow. Sharing insights and success stories in the community can accelerate collective knowledge, propelling the industry toward faster and more dependable auto repairs.

,

Harnessing AI and Data Analytics to Detect Transmission Anomalies Early

The evolution of diagnostic technology now empowers auto repair professionals to utilize artificial intelligence (AI) and data analytics for predictive maintenance. By analyzing vast datasets from vehicle sensors and historical repair records, technicians can identify subtle transmission irregularities before they manifest as critical failures. This proactive approach not only minimizes repair costs but also extends vehicle lifespan, fundamentally transforming traditional reactive maintenance models.

Integrating Virtual Reality into Transmission Repair Training

One of the most innovative advances shaping transmission repair proficiency is the incorporation of virtual reality (VR) simulations. These immersive training environments allow technicians to engage with complex transmission systems in a risk-free, controlled setting. Hands-on experience with virtual models accelerates skill acquisition, enhances understanding of intricate mechanisms, and reduces error rates during actual repairs. As industry leaders endorse, VR-powered training is becoming an indispensable asset in cultivating expert auto technicians.

Deciphering Complex Fault Codes with Machine Learning Algorithms

Traditional fault codes provide valuable insights, yet they often require interpretation aligned with context-specific variables. Machine learning algorithms elevate diagnostic accuracy by correlating fault codes with a multitude of operational parameters, environmental conditions, and driver behaviors. These intelligent systems adapt over time, refining their predictions and enabling technicians to pinpoint root causes with unprecedented precision. Embracing such technological sophistication positions repair shops at the forefront of automotive maintenance excellence.

Is Your Shop Ready to Transition to Automated Diagnostic Ecosystems?

Transitioning from manual diagnostics to fully automated ecosystems involves a significant shift, encompassing hardware upgrades, software integration, and staff training. Although initial investments may seem substantial, the long-term benefits include faster turnaround times, reduced human error, and improved diagnostic-consistency. Industry insights from authoritative sources like AutoTransportIntel highlight how early adoption of these systems can serve as a competitive advantage. Exploring modular, scalable diagnostic platforms enables repair facilities to adapt seamlessly as technology evolves.

What are the potential pitfalls of over-relying on automated diagnostics, and how can experts mitigate them?

While automation significantly enhances diagnostic speed and accuracy, over-reliance can obscure nuanced mechanical assessments and reduce the critical thinking skills of technicians. To mitigate these risks, it is vital to maintain a balanced approach that combines human expertise with machine efficiency. Continuous education, regular calibration of diagnostic tools, and fostering a culture of diagnostic skepticism ensure that technological aids complement rather than replace the technician’s judgment. Maintaining this synergy is crucial for delivering precise, reliable transmission repairs amidst rapidly advancing automotive technology.

Harnessing Predictive Analytics for Proactive Transmission Care

The automotive industry is witnessing a paradigm shift with the integration of predictive analytics in transmission diagnostics. By leveraging vast datasets collected from vehicle telematics and maintenance histories, technicians can preemptively identify looming failures, thereby reducing unscheduled repairs and enhancing vehicle longevity. This approach aligns with the principles outlined in the comprehensive study by the Transmission Industry Journal, emphasizing data-driven maintenance models that transform traditional reactive strategies.

Why Are Digital Twins Becoming Game-Changers in Transmission Repairs?

Digital twin technology offers a virtual replica of a vehicle’s transmission system, enabling detailed simulation of mechanical and electronic interactions under various operating conditions. This immersive model allows technicians to diagnose faults with remarkable precision, test repair scenarios virtually, and predict future component wear—ultimately streamlining workflows and minimizing trial-and-error in physical repairs. Industry leaders like Siemens have pioneered this integration, demonstrating its capacity to elevate auto repair standards and deliver faster, more accurate service.

Disrupting Diagnostic Norms with Quantum Computing

While still in nascent stages, quantum computing holds promise for revolutionizing transmission diagnostics by processing complex, high-dimensional data at unprecedented speeds. This technological leap could enable real-time analysis of mechanical vibrations, fluid dynamics, and electronic signals, uncovering issues that conventional systems might miss. As automotive R&D labs and tech giants explore this frontier, forward-thinking repair shops are encouraged to monitor these developments to stay ahead in diagnostic innovation.

Navigating the Ethical Landscape of Intelligent Diagnostics

The deployment of AI-driven diagnostic tools introduces ethical considerations around data privacy, algorithmic transparency, and technician oversight. Ensuring that machine learning models are free from biases and that customer data remains secure is paramount. Moreover, maintaining the technician’s role as a critical thinker and decision-maker safeguards professional integrity. Adhering to standards set forth by organizations like the Auto Safety Institute ensures responsible adoption of these powerful technologies.

Expert Tips for Seamless Integration of Advanced Diagnostics

To maximize the benefits of emerging diagnostic tools, auto repair facilities should invest in comprehensive staff training, foster a culture receptive to technological change, and develop standardized protocols that combine manual expertise with AI insights. Collaborating with industry consortia and participating in ongoing education initiatives accelerates adaptation and mitigates potential pitfalls associated with technological obsolescence. Remember, the true mastery lies in harmonizing human skill with machine intelligence, creating a synergy that sets new benchmarks in transmission repair excellence.

Expert Insights & Advanced Considerations

Leverage Real-Time Data for Precision Tuning

Integrating live vehicle data streams into diagnostics allows technicians to identify subtle transmission anomalies before they manifest as failures, enabling proactive interventions that save time and resources.

Utilize AI-Powered Predictive Models

Advanced machine learning algorithms analyze patterns from extensive sensor datasets, predicting potential malfunctions with remarkable accuracy and facilitating swift, targeted repairs.

Incorporate Virtual Reality for Skill Enhancement

VR simulations provide immersive training experiences, allowing technicians to familiarize themselves with complex transmission systems in a risk-free environment, accelerating proficiency and reducing repair errors.

Stay Ahead with Digital Twin Technology

Creating a virtual replica of transmission components enables virtual testing and diagnostics, reducing diagnostic cycles and enabling real-time troubleshooting with minimal vehicle downtime.

Balance Automation with Expertise

While automated diagnostics enhance speed and accuracy, maintaining human oversight ensures nuanced understanding and prevents over-reliance on technology, safeguarding repair quality.