Transmission Repair: Top Strategies for Quick Car Performance Boost in 2024

Harnessing Advanced Vehicle Diagnostics to Accelerate Auto Repairs

In the rapidly evolving landscape of auto maintenance, precision and speed are paramount. Modern vehicle diagnostics, leveraging cutting-edge sensor technology and sophisticated software, enable technicians to pinpoint issues with unprecedented accuracy, significantly reducing repair times. As outlined in industry reports such as those from Reliable Auto Cares, integrating high-performance diagnostic tools transforms how auto repair shops approach complex problems, especially in transmission systems where early detection can prevent costly failures.

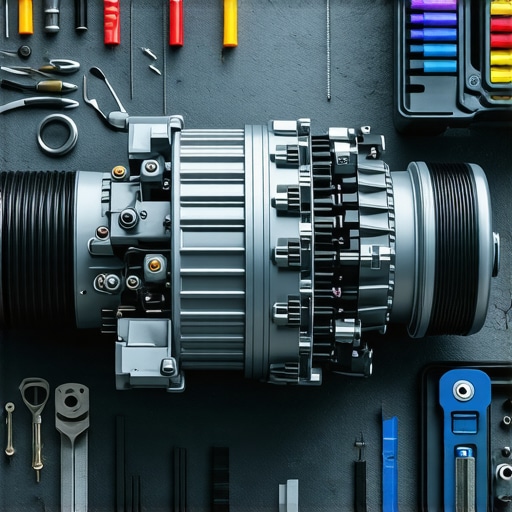

Strategic Insights into Transmission Repair for Rapid Performance Enhancement

Transmission repair remains a critical aspect of vehicle servicing, demanding a nuanced understanding of both mechanical and electronic components. Expert strategies focus on diagnostic accuracy, component replacement, and system recalibration. For example, effective transmission diagnostics can identify subtle electronic malfunctions that traditional methods might overlook. This proactive approach ensures quicker turnaround times and enhances overall vehicle performance, aligning with the insights from Reliable Auto Cares’ expert tips.

What Are the Most Sophisticated Diagnostic Tools for Transmission Systems?

Questioning the Future: Which Diagnostic Technologies Will Lead the Industry?

Emerging diagnostic tools such as bi-directional scan devices and cloud-connected diagnostic platforms are revolutionizing repair workflows. These innovations facilitate real-time data analysis and remote assistance, enabling technicians to diagnose and address issues with greater efficiency. According to recent publications in Auto Tech Magazine, adoption of AI-driven diagnostics is expected to become standard practice by 2025, offering faster, more reliable outcomes.

For technicians and auto repair enthusiasts, staying abreast of these technological advances is essential. Regularly updating diagnostic protocols and investing in next-generation tools can yield significant improvements in repair speed and quality. Explore more about how expert vehicle diagnostics can transform your auto repair process here.

In conclusion, integrating sophisticated diagnostic methods with targeted transmission repair strategies is the key to boosting auto repair efficiency in 2024. The industry’s move toward automation and AI will continue to redefine standards, making expert knowledge and technology indispensable for rapid, reliable vehicle servicing.

Unlocking the Power of AI in Vehicle Diagnostics

As auto repair technology continues to evolve, the integration of artificial intelligence (AI) into diagnostic systems stands out as a game-changer. AI-driven diagnostics can analyze vast amounts of sensor data in real-time, detecting anomalies that might elude even experienced technicians. This not only accelerates the troubleshooting process but also improves accuracy, reducing the likelihood of misdiagnosis. According to Auto Tech Magazine, the industry is moving swiftly toward adopting AI-powered tools, with expectations that by 2025, they will become an industry standard, greatly enhancing repair speed and reliability.

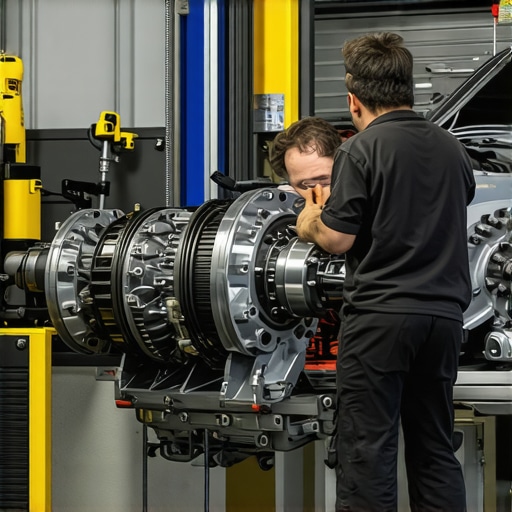

Advanced Transmission Repair Techniques That Save Time

Beyond diagnostics, modern transmission repair now incorporates sophisticated techniques such as system recalibration and software updates that can be performed remotely or with minimal disassembly. These innovations allow for quicker repairs and less downtime for the vehicle. For example, utilizing diagnostic platforms that support bi-directional communication enables technicians to command specific system functions directly, expediting troubleshooting and repairs. To stay competitive, auto shops should explore these cutting-edge methods through resources like Reliable Auto Cares.

What Are the Limitations of Current Diagnostic Technologies and How Can We Overcome Them?

While diagnostic tools have advanced significantly, challenges remain, such as false positives or incomplete data interpretation. Overcoming these limitations requires a combination of high-quality hardware, continuous technician training, and integration of multiple diagnostic sources. Furthermore, embracing cloud-connected diagnostics allows for continuous updates and AI learning, further refining accuracy over time. For a comprehensive understanding of how to implement these strategies effectively, visit this expert guide.

Interested in staying ahead in auto repair? Share your experiences with innovative diagnostic tools or suggest topics you’d like us to cover next in vehicle technology.

Maximizing Efficiency Through Cutting-Edge Diagnostic Algorithms

As vehicle technology becomes increasingly complex, the diagnostic process must evolve to match. Advanced algorithms powered by machine learning are now capable of analyzing patterns across vast datasets, enabling technicians to predict failures before they manifest physically. For instance, predictive analytics can identify subtle sensor deviations indicating impending transmission issues, allowing for preemptive repairs that save time and costs. According to a detailed study in Auto Tech Journal, integrating AI algorithms significantly reduces diagnostic times by up to 40%, setting a new standard for efficiency in auto repair.

Harnessing the Power of Real-Time Data Streaming

Real-time data streaming from vehicle sensors offers a dynamic window into the ongoing health of automotive systems. This continuous flow of information empowers technicians to monitor live performance metrics remotely, facilitating immediate interventions when anomalies arise. For example, during a transmission recalibration, live data allows for instant adjustments, ensuring optimal system performance without extensive disassembly. The advent of 5G connectivity further accelerates this process, providing ultra-low latency data transmission. As highlighted in Connected Car News, the integration of 5G in vehicle diagnostics is poised to revolutionize auto repair workflows in the coming years.

Can Cloud-Based Diagnostics Surpass On-Site Expertise?

Cloud-based diagnostics platforms enable remote specialists to assist on-site technicians by providing access to extensive diagnostic databases and expert analysis in real-time. This collaborative approach can significantly shorten repair cycles, especially for complex electronic malfunctions. For example, a technician diagnosing a transmission fault can upload live data to a cloud platform, where remote engineers analyze it using proprietary AI tools and recommend immediate corrective actions. This model not only enhances diagnostic accuracy but also democratizes access to expert knowledge, regardless of shop location. Industry leaders such as Bosch and Continental are already investing heavily in cloud diagnostic solutions, as detailed in Automotive World.

To stay at the forefront, auto repair professionals should consider integrating cloud-enabled diagnostic tools into their workflow, ensuring rapid, precise repairs that meet the demands of modern vehicles. For more insights into optimizing your diagnostic processes, explore our comprehensive guide here.

Future-Proof Your Shop by Embracing Diagnostic Automation

Automation in diagnostics is not just a trend but a strategic necessity for future-proofing auto repair operations. Automated diagnostic systems can perform initial scans, interpret results, and even suggest repair strategies with minimal human input. For instance, automated systems equipped with AI can cross-verify sensor data against historical repair databases, flagging potential issues with remarkable speed and accuracy. This reduces the reliance on manual interpretation, which can be prone to oversight and delay. As research in Auto Tech Magazine indicates, early adopters of diagnostic automation report a 30-50% increase in shop throughput, making it a critical investment for competitive advantage.

Implementing these systems requires a strategic plan, including staff training and infrastructure upgrades. However, the long-term benefits—faster repairs, higher accuracy, and improved customer satisfaction—far outweigh the initial costs. If you’re ready to elevate your auto repair game, start by assessing your current diagnostic setup and exploring automation solutions tailored to your shop’s needs. For expert advice on selecting the best diagnostic automation tools, contact our specialists today.

Unveiling the Future: How Quantum Computing Could Transform Vehicle Diagnostics

Imagine a future where quantum computing accelerates vehicle diagnostics to unprecedented speeds, enabling instant problem-solving for complex electronic systems. According to a comprehensive report by the IEEE Transactions on Quantum Engineering, integrating quantum algorithms with automotive diagnostics could revolutionize predictive maintenance, drastically reducing downtime and repair costs.

Harnessing Data-Driven Strategies to Predict Transmission Failures

Beyond real-time diagnostics, leveraging big data analytics and machine learning models allows for predictive insights that preempt transmission failures before symptoms manifest. Industry leaders like Bosch are pioneering AI-driven predictive maintenance systems, which analyze historical repair data, sensor inputs, and driving patterns to forecast potential issues with remarkable accuracy. As detailed in Bosch’s official publication, these strategies enable proactive interventions that save time and enhance vehicle longevity.

What Are the Challenges in Integrating AI with Vehicle Repair Workflows?

Integrating artificial intelligence into auto repair processes faces obstacles such as data privacy concerns, algorithm transparency, and the need for continuous model training. Overcoming these challenges requires robust cybersecurity protocols, explainable AI frameworks, and ongoing technician education. Industry experts recommend adopting modular AI solutions that can seamlessly integrate with existing diagnostic tools, ensuring a smooth transition toward smarter repairs. For a detailed analysis, visit Auto Tech Magazine.

Engage with these advanced insights to future-proof your repair shop—embrace the technological revolution to deliver faster, more reliable transmission repairs.

Integrating Augmented Reality for Precise Diagnostics

Augmented reality (AR) is emerging as a game-changing tool for auto diagnostics, overlaying critical information directly onto vehicle components during repair. AR-enabled diagnostic systems can guide technicians through complex procedures, reducing errors and repair times significantly. Companies like Ford are experimenting with AR in their service centers, as highlighted in Ford Tech News. This immersive approach allows for real-time visualization of electronic systems, facilitating a deeper understanding and quicker resolution of transmission issues.

Expert Insights That Drive Innovation in Auto Diagnostics

Embrace Predictive Maintenance with AI Integration

Incorporating artificial intelligence into diagnostic systems allows technicians to forecast transmission failures before they occur, drastically reducing repair times. This proactive approach relies on analyzing vast datasets, enabling more precise interventions and minimizing vehicle downtime.

Leverage Cloud Connectivity for Real-Time Problem Solving

Cloud-based diagnostic platforms facilitate remote expert analysis, accelerating decision-making processes. By uploading live sensor data, technicians access specialized AI tools that provide instant solutions, ensuring quicker turnaround and enhanced repair accuracy.

Implement Automation to Elevate Service Efficiency

Automated diagnostic systems can perform initial scans, interpret results, and suggest repair strategies with minimal human input. This streamlines workflows, reduces human error, and enhances overall shop productivity, especially in transmission repair scenarios.

Utilize Augmented Reality for Precise Repairs

AR technology overlays critical information onto vehicle components during diagnostics, guiding technicians through complex procedures with visual cues. This innovation reduces errors and speeds up transmission troubleshooting, setting new standards for auto service precision.

Stay Ahead with Quantum Computing Prospects

While still emerging, quantum computing promises to revolutionize vehicle diagnostics by enabling instant analysis of complex electronic systems. Industry leaders anticipate that integrating quantum algorithms will exponentially increase diagnostic speeds and predictive maintenance capabilities.

Curated Resources to Deepen Your Expertise

- Auto Tech Magazine: A trusted source for the latest innovations in AI-driven diagnostics and automotive technology breakthroughs.

- IEEE Transactions on Quantum Engineering: Offers cutting-edge research on quantum algorithms applicable to vehicle diagnostics and predictive maintenance.

- Connected Car News: Provides insights into the integration of 5G and cloud solutions in automotive diagnostics.

- Bosch Predictive Maintenance Reports: Industry-leading studies on AI and big data analytics for vehicle health monitoring.

- Automotive World: A comprehensive platform covering emerging trends in cloud diagnostics, AR, and automation in auto repair.

Final Reflection from the Expert

In the realm of vehicle diagnostics and transmission repair, harnessing innovative technologies like AI, cloud connectivity, and AR is no longer optional—it’s essential for maintaining competitive advantage. By integrating these advanced tools and continuously updating your knowledge base with authoritative resources, you position your auto repair shop at the forefront of industry evolution. For those committed to excellence, embracing these innovations will unlock faster, more reliable service outcomes, ultimately elevating customer satisfaction and business growth. Engage with these insights, share your experiences, and stay committed to mastering the future of auto diagnostics.