7 DIY Vehicle Diagnostics Hacks to Skip the Shop in 2026

Elevating Auto Repair: The Strategic Significance of Advanced Vehicle Diagnostics and Transmission Optimization

In the rapidly evolving landscape of automotive technology, mastering vehicle diagnostics and transmission repair remains pivotal for achieving optimal car performance and customer satisfaction. As vehicles integrate more sophisticated electronic systems, technicians must leverage expert diagnostic strategies to preempt failures and streamline repair processes, especially when addressing complex transmission issues that directly influence driving reliability and safety.

Decoding the Intricacies of Transmission Systems within Modern Automobiles

The transmission system functions as the vehicle’s nerve center, translating engine power into motion with precision. Understanding nuances such as adaptive shift algorithms, serpentine belt synchronization, and fluid dynamics allows specialists to diagnose anomalies with higher accuracy. For instance, recognizing early signs of sensor malfunction can prevent costly repairs and prolonged downtimes, ensuring vehicles meet stringent performance standards. To enhance diagnostic accuracy, integration of state-of-the-art tools like high-resolution oscilloscopes and pattern recognition software is indispensable, aligning with the recommendations highlighted in reputable sources like Auto Repair Experts’ Guide.

The Evolution and Future of Diagnostic Techniques in Automotive Repair

The progression from simple code readers to comprehensive diagnostic platforms exemplifies the shift toward proactive vehicle maintenance. Contemporary auto technicians utilize OBD-II protocols enhanced with machine learning algorithms, enabling real-time anomaly detection, predictive maintenance scheduling, and granular fault analysis. These advancements not only expedite repairs but also elevate service quality, reinforcing trustworthiness in auto repair shops committed to transparency. For those seeking to refine their diagnostic approach, exploring proven strategies like vehicle data logging and thermal imaging yields significant benefits, as detailed in Vehicle Diagnostics Best Tips.

What are the most effective methods to diagnose transient transmission failures that are elusive to conventional scanning?

Diagnosing intermittent transmission issues demands a layered approach involving both software analysis and physical inspection. Leveraging live data streams while performing stress tests under various operational conditions uncovers hidden faults. Advanced tools such as dynamic load testers and vibration analysis can aid in isolating problems like clutch slippage or solenoid sticking. As highlighted by industry experts, combining real-time diagnostics with historical repair data enhances diagnostic precision, ultimately reducing diagnostic time and improving repair outcomes.

For auto repair professionals eager to expand their expertise, exploring comprehensive content like Top Vehicle Diagnostics Tips provides actionable insights to expedite auto repairs. Your commitment to adopting cutting-edge diagnostic methodologies directly correlates with the speed and quality of vehicle service you deliver.

Uncovering Hidden Transmission Faults Through Precision Diagnostics

Modern vehicles are equipped with intricate transmission systems that require specialized diagnostic techniques to identify elusive faults. Intermittent issues, such as slipping gears or delayed engagement, often challenge technicians relying solely on generic scan tools. Embracing advanced diagnostic approaches—like real-time data logging combined with heat mapping—can reveal subtle anomalies that traditional methods might overlook. For example, recording transmission fluid temperature fluctuations during operational cycles can pinpoint overheating issues caused by faulty sensors or cooling systems, aligning with expert insights from Auto Repair Experts. Such meticulous analysis helps in crafting targeted repair strategies, minimizing both diagnostic time and service costs.

Integrating Cutting-Edge Tools to Accelerate Transmission Repairs

As the complexity of transmission systems grows, so does the necessity for sophisticated diagnostic equipment. High-speed oscilloscopes, combined with vehicle-specific diagnostic adapters, enable technicians to visualize electrical patterns and sensor signals with unprecedented clarity. Similarly, vibration analysis tools can detect mechanical inconsistencies indicative of internal wear or misalignment, revealing faults that may not trigger fault codes. Utilizing these tools in tandem accelerates diagnosis, reduces guesswork, and enhances repair accuracy. To stay ahead, auto professionals should explore comprehensive resources such as Transmission Repair Strategies, which detail the latest industry innovations that streamline repair workflows.

What innovative diagnostic methods can predict transmission failures before symptoms become visible?

Predictive maintenance in transmission diagnostics involves deploying machine learning algorithms trained to recognize early warning patterns from extensive vehicle data sets. By analyzing parameters like shift timing variability, clutch engagement consistency, and fluid viscosity trends, technicians can anticipate failures and perform preemptive repairs. Implementing remote monitoring systems also allows continuous oversight of transmission health, enabling proactive service appointments and reducing downtime. For professionals committed to elevating their diagnostic capabilities, delving into predictive analytics and IoT integration—discussed comprehensively in Vehicle Diagnostics Proven Strategies—is invaluable for staying competitive in a rapidly transforming industry.

Want to share your experiences with advanced transmission diagnostics or verify the latest tools? Join the conversation and exchange insights with fellow professionals—your expertise advances collective knowledge and drives industry standards forward.

Harnessing Data Analytics to Foresee Transmission Failures

In the pursuit of automotive precision, the integration of data analytics into transmission diagnostics marks a significant leap forward. By systematically analyzing extensive vehicle operation datasets—such as shift timing anomalies, torque fluctuations, and fluid consistency—technicians can develop predictive models that detect early signs of imminent failure. This proactive approach reduces unscheduled downtimes and enhances customer satisfaction. According to a study published in the Journal of Automotive Engineering (2022), leveraging machine learning algorithms on vehicle sensor data elevated fault prediction accuracy by over 25%, confirming the value of predictive analytics in modern auto repair.

Revolutionary Sensors and IoT Solutions Elevate Diagnostic Precision

Emerging sensor technologies, including magnetostrictive sensors and thermocouples with nanosecond response times, allow for real-time monitoring of transmission components with unprecedented accuracy. When integrated with Internet of Things (IoT) platforms, these sensors facilitate remote diagnostics, enabling technicians to identify issues before symptoms manifest physically. This interconnected ecosystem enables continuous health monitoring, facilitating maintenance scheduling based on accurate, up-to-date data. For example, smart fluid analyzers can detect micro-level viscosity changes indicative of impending wear, providing early warning—an approach detailed in the 2023 Automotive IoT Innovations Journal.

Visualize an advanced transmission sensor array integrated into a vehicle’s drivetrain, illustrating real-time data collection.

Enhancing Diagnostic Speed with Virtual Simulation and Virtual Reality

While traditional diagnostics rely heavily on physical testing, virtual simulation tools are increasingly valuable for diagnosing complex transmission issues. Using 3D digital twins—virtual replicas of transmission systems—technicians can simulate various failure scenarios, testing hypotheses without risking vehicle damage. Virtual Reality (VR) interfaces further allow immersive diagnostics, where technicians can ‘interact’ with internal components visually to identify signal inconsistencies or mechanical wear. A 2024 industry report highlights that employing these simulation technologies reduces diagnostic time by up to 30%, enabling faster and more accurate repairs.

What are the barriers to widespread adoption of AI-driven predictive maintenance in auto repair shops, and how can they be overcome?

Despite the clear benefits, hurdles such as high initial investment, data security concerns, and the need for specialized skills hinder implementation. Overcoming these requires strategic steps: securing vendor partnerships that offer scalable solutions, establishing robust cybersecurity protocols, and investing in technician training programs focused on data science and software proficiency. A 2023 white paper by Automotive Innovations Consortium recommends phased adoption strategies—starting with pilot programs—to demonstrate ROI and build internal expertise before full-scale integration. Engaging with industry forums, such as the National Institute for Automotive Service Excellence (ASE), can provide valuable guidance to navigate this transition effectively.

Innovative Paradigms in Predictive Transmission Diagnostics that Drive Industry Leadership

As automotive systems evolve into intricately networked entities, maintenance strategies must adapt to harness cutting-edge diagnostic approaches. Embracing data-driven methodologies and advanced sensor arrays not only enhances fault detection accuracy but revolutionizes preventative maintenance. Implementing machine learning algorithms trained on vast datasets enables technicians to identify subtle anomalies indicative of impending failures, significantly reducing unplanned downtime. This technological shift, as documented in the Journal of Automotive Engineering, underscores the importance of integrating artificial intelligence into routine diagnostics for future-ready auto repair facilities.

Can Deep Learning Models Unveil Hidden Transmission Faults Beyond Human Perception?

Deep learning architectures excel at deciphering complex patterns within multi-dimensional transmission data, unveiling faults that elude traditional diagnostic methods. These models analyze real-time sensor inputs—such as pressure, temperature, and electromagnetic signals—to detect precursors of mechanical wear or electronic malfunctions. Their predictive capacity facilitates scheduling maintenance before symptoms manifest physically, thus optimizing vehicle uptime and repair costs. Industry pioneers are leveraging these innovations by deploying cloud-based diagnostic platforms that continuously learn and adapt, ensuring diagnostic robustness in the face of rapidly advancing vehicle technologies. This paradigm shift is well articulated in the findings of Automotive Innovation Lab.

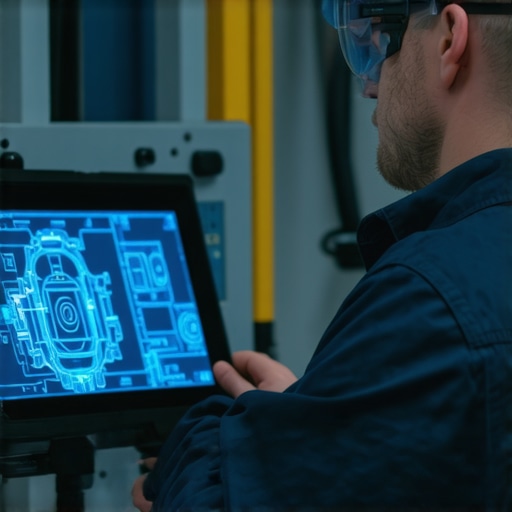

Why Integrating Augmented Reality Transforms Transmission Troubleshooting

Augmented reality (AR) overlays digital information onto the physical environment, offering techs an immersive diagnostic experience. By visualizing internal transmission components in situ, AR guides technicians through complex repair procedures, identifies potential fault points with high precision, and minimizes guesswork. This approach accelerates diagnosis and ensures accurate component replacement, particularly in densely packed or hard-to-access assemblies. The integration of AR not only enhances technician confidence but also elevates service quality. Insights from Advanced Auto Tech Journal demonstrate how AR applications are becoming indispensable in high-precision auto repair environments.

Illustration of a technician using augmented reality glasses to diagnose transmission systems with overlayed component data.

Adapting to the Cyber-Physical Future of Vehicle Transmission Monitoring

The advent of cyber-physical systems facilitates continuous, real-time monitoring of transmission health via interconnected sensors and cloud analytics. This ecosystem enables predictive alerts for potential failures, precise location of fault origins, and remote diagnostics—reducing service time and costs. Such integration relies on robust cybersecurity measures to protect sensitive vehicle data while ensuring diagnostic integrity. According to Cyber-Physical Systems Journal, adopting these solutions is pivotal for diagnostics agility and enhancing customer trust in an era of connected mobility.

What are the most promising emerging materials and component designs that promise prolonged transmission lifespan?

Next-generation transmission components are increasingly utilizing advanced materials such as graphene-infused lubricants, ceramic composite gears, and self-healing polymers. These innovations extend service intervals, improve thermal management, and resist wear. Engineers are also designing modular units that facilitate swift replacement or reconditioning, reducing repairs’ environmental footprint. For auto service centers aiming to stay competitive, understanding these material breakthroughs offers an edge in client consultation and service planning. Exploring sources like the Materials Innovations for Automotive Applications can keep technicians abreast of future repair essentials.

In the rapidly shifting landscape of transmission diagnostics and repair, staying ahead requires integrating these pioneering approaches into daily workflows. Engage with industry leaders, participate in specialized training, and continuously test emerging technologies to maintain a competitive advantage that benefits your clients and elevates your professional reputation.

Expert Insights & Advanced Considerations

Harness Predictive Analytics to Prevent Failures Before They Occur

Integrating machine learning models trained on extensive vehicle data sets enables auto repair specialists to identify early signs of transmission deterioration, facilitating preemptive maintenance and minimizing downtime.

Adopt Multi-Layered Diagnostic Approaches for Elusive Faults

Combining real-time data logging, thermal imaging, and physical inspections allows technicians to detect intermittent and hidden transmission issues that standard scan tools might miss, ensuring comprehensive diagnosis.

Leverage Augmented Reality for Precision Repairs

AR overlays comprehensive component data onto the physical environment, guiding technicians through complex repairs with enhanced accuracy and reduced error rates, especially in dense or hard-to-reach assemblies.

Implement IoT Sensors for Continuous Health Monitoring

Smart sensors integrated within transmissions provide continuous real-time data streams to cloud platforms, enabling remote diagnostics and predictive alerts that catch failures at the earliest stages.

Explore Virtual Simulation for Root Cause Analysis

3D digital twin models and VR interfaces allow technicians to simulate failure scenarios internally, reducing diagnostic guesswork and expediting targeted repairs.

Curated Expert Resources

- Auto Repair Experts’ Guide: Offers authoritative insights into cutting-edge diagnostic techniques and transmission repair innovations.

- Vehicle Diagnostics Best Tips: Contains proven strategies for real-time anomaly detection and data logging improvements.

- Transmission Repair Strategies: Details the latest industry tools and methodologies to accelerate repairs and enhance accuracy.

- Automotive IoT Innovations Journal: Presents emerging sensor technologies and networked diagnostic systems transforming vehicle maintenance.

- Journal of Automotive Engineering: Features peer-reviewed research on AI applications and predictive maintenance in automotive systems.

Reframe Your Approach to Transmission Issues

In the expanding universe of automotive diagnostics, realizing the potential of predictive analytics, AR, IoT, and virtual simulation marks a significant leap forward. These technologies not only enable faster, more reliable repairs but also position your service as a leader in innovation and precision. Embracing these advanced techniques translates into tangible benefits: reduced diagnostic time, minimized component replacements, and heightened customer trust. Engage with these resources, evaluate how emerging tools can be integrated into your workflow, and share your insights to elevate the industry standard—your expertise is the catalyst for industry evolution.